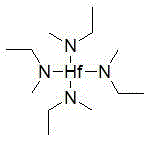

Tetrakis(ethylmethylamino)hafnium synthesis method

A synthetic method, ethylamino technology, applied in chemical instruments and methods, compounds of group 4/14 elements of the periodic table, organic chemistry, etc., can solve problems such as increasing operation difficulty and cost, reducing reaction efficiency, and difficulty in filtration and separation , to achieve the effect of saving reaction cost, simple operation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: the synthesis of hafnium tetramethylethylamino

[0025] (1) Under an inert atmosphere, add 130 g of methylethylamine and 600 mL of n-hexane into a 2000 mL three-necked flask, stir mechanically, and place the reaction flask at -10°C. Add 800 mL of 2.5 mol / L n-butyllithium in n-hexane solution dropwise into the reaction flask. After the dropwise addition, the reaction was stirred for 5 hours.

[0026] (2) Add 160 grams of hafnium tetrachloride into the above reaction system, and keep the temperature of the reaction system not higher than 60°C. After adding hafnium tetrachloride, let the reaction system react for 18 hours under the condition of mechanical stirring and inert gas protection.

[0027] (3) After the reaction is over, change the reaction device directly into a distillation device, remove the reaction solvent under normal pressure, wait for the solvent n-hexane to be completely removed, distill under reduced pressure, and collect the fraction at ...

Embodiment 2

[0028] Embodiment 2: the synthesis of hafnium tetramethylethylamino

[0029] (1) Under an inert atmosphere, add 236 g of methylethylamine and 500 mL of n-hexane into a 2000 mL three-necked bottle, stir mechanically, and place the reaction bottle at -50 °C. Add 800 mL of 2.5 mol / L n-butyllithium in n-hexane solution dropwise into the reaction flask. After the dropwise addition, the reaction was stirred for 12 hours.

[0030] (2) Add 160 grams of hafnium tetrachloride into the above reaction system, and keep the temperature of the reaction system not higher than 60°C. After adding the hafnium tetrachloride, let the reaction system react for 30 hours under the condition of mechanical stirring and inert gas protection.

[0031] (3) After the reaction is over, change the reaction device directly into a distillation device, remove the reaction solvent under normal pressure, wait for the solvent n-hexane to be completely removed, distill under reduced pressure, and collect the frac...

Embodiment 3

[0032] Embodiment 3: the synthesis of tetramethylethylamino hafnium

[0033] (1) Under an inert atmosphere, add 177 g of methylethylamine and 700 mL of n-hexane into a 2000 mL three-necked bottle, stir mechanically, and place the reaction bottle at -80 °C. Add 800 mL of 2.5 mol / L n-butyllithium in n-hexane solution dropwise into the reaction flask. After the dropwise addition, the reaction was stirred for 10 hours.

[0034] (2) Add 160 grams of hafnium tetrachloride into the above reaction system, and keep the temperature of the reaction system not higher than 60°C. After adding hafnium tetrachloride, let the reaction system react for 20 hours under the condition of mechanical stirring and inert gas protection.

[0035](3) After the reaction is over, change the reaction device directly into a distillation device, remove the reaction solvent under normal pressure, wait for the solvent n-hexane to be completely removed, distill under reduced pressure, and collect the fraction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com