A kind of method for preparing oil-soluble medicine slow-release capsule

A slow-release capsule and oil-soluble technology, which is applied in the field of preparing oil-soluble drug sustained-release capsules, can solve the problems of too fast release process, high toxicity and high drug cost, and achieves controllable release process, low production cost, and reduced drug concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

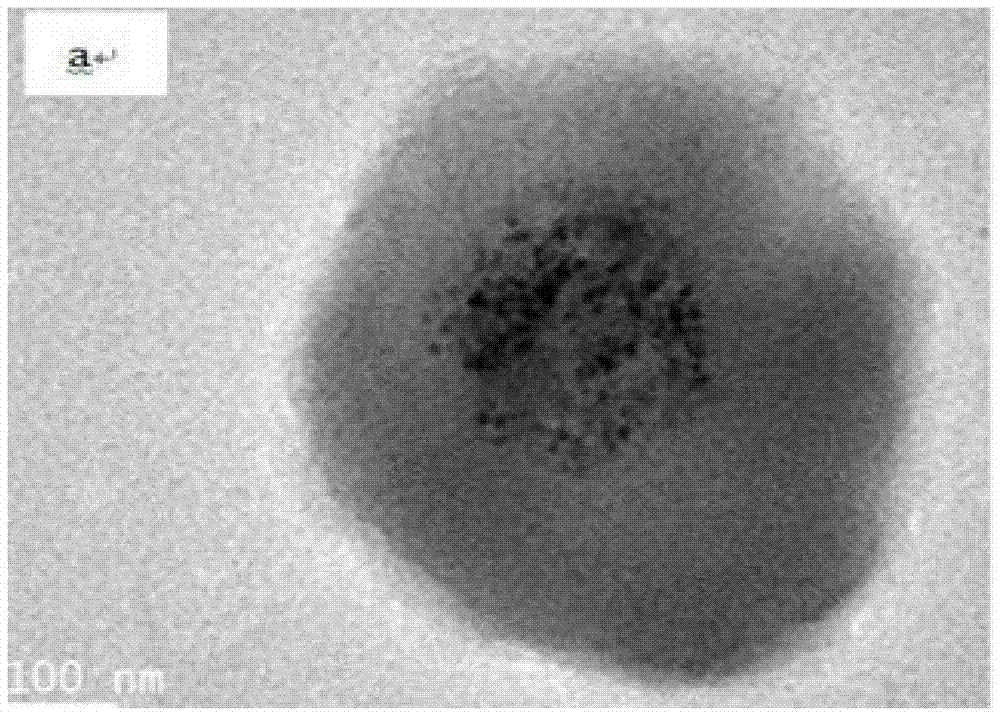

[0032] Weigh 25.0g of deionized water and 0.5g of surfactant in a 100ml small beaker, heat and stir after dissolving, set the temperature at 100°C, add 6.6g of 30% SiO2 drop by drop 2 (particle size is 3nm) in a small beaker, stir vigorously to make it uniform and form SiO 2 Emulsion: Weigh 5.2g of Sudan Red III, 1.1g of petroleum ether with a dissolution range of 90-120°C, and 6.3g of sliced paraffin wax with a dissolution range of 52-56°C, stir for 3 minutes to make it uniform; add the paraffin wax mixture to In the silicon dioxide emulsion, after vigorous stirring, the temperature was lowered for processing to form a Pickering emulsion.

[0033] Weigh 3.5g of Pickering emulsion, add 42.0g of silica sol (containing 0.6g of silicon dioxide) formed by sol-gel method and 4.5g of surfactant to further deposit and coat paraffin wax particles to form drug sustained release capsule.

[0034] After 6 hours, it was washed and filtered twice, and the powder was dried in a ventilat...

Embodiment 2

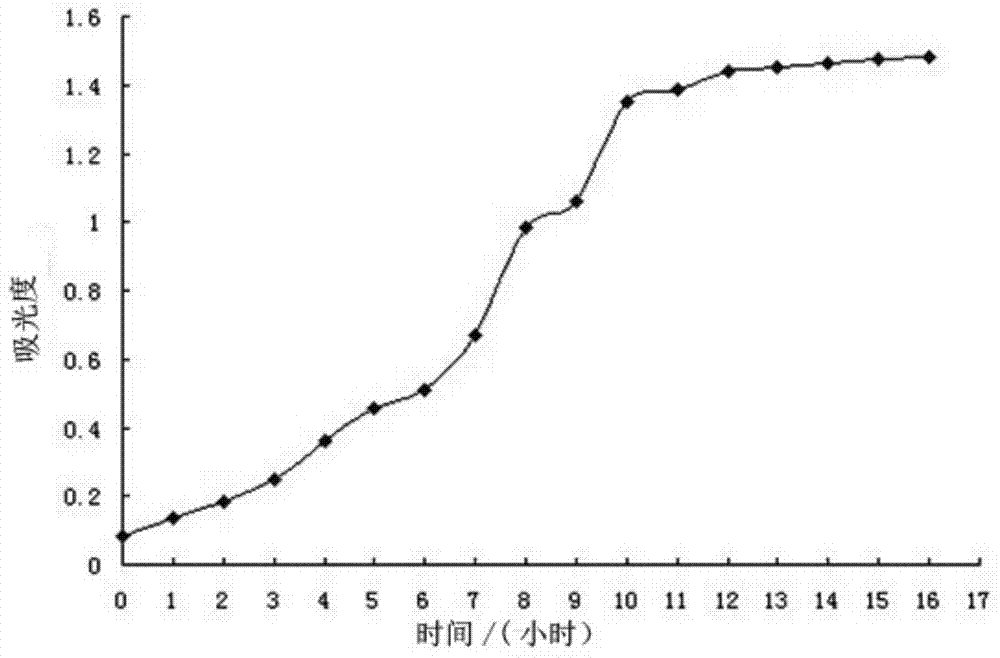

[0036] Weigh 25.0g of deionized water and 0.5g of surfactant in a 100ml small beaker, heat and stir after dissolving, set the temperature at 100°C, add 6.6g of 30% SiO2 drop by drop 2 (Particle size is 50nm) in a small beaker, stir vigorously to make it uniform and form SiO 2 Emulsion: Weigh 0.5mg of Sudan Red III, 0.1mg of petroleum ether with a dissolution range of 90-120°C and 12.6g of sliced paraffin wax with a dissolution range of 52-56°C, stir for 3 minutes to make it uniform; add the paraffin wax mixture to In the silicon dioxide emulsion, after vigorous stirring, the temperature was lowered for processing to form a Pickering emulsion.

[0037] Weigh 3.5g of Pickering emulsion, add 42.0g of industrial-grade silica sol (containing 1.0g of silicon dioxide) and 4.5g of surfactant to further deposit and coat the paraffin particles to form drug sustained-release capsules.

[0038] After 6 hours, it was washed with water and filtered twice, and the powder was dried and col...

Embodiment 3

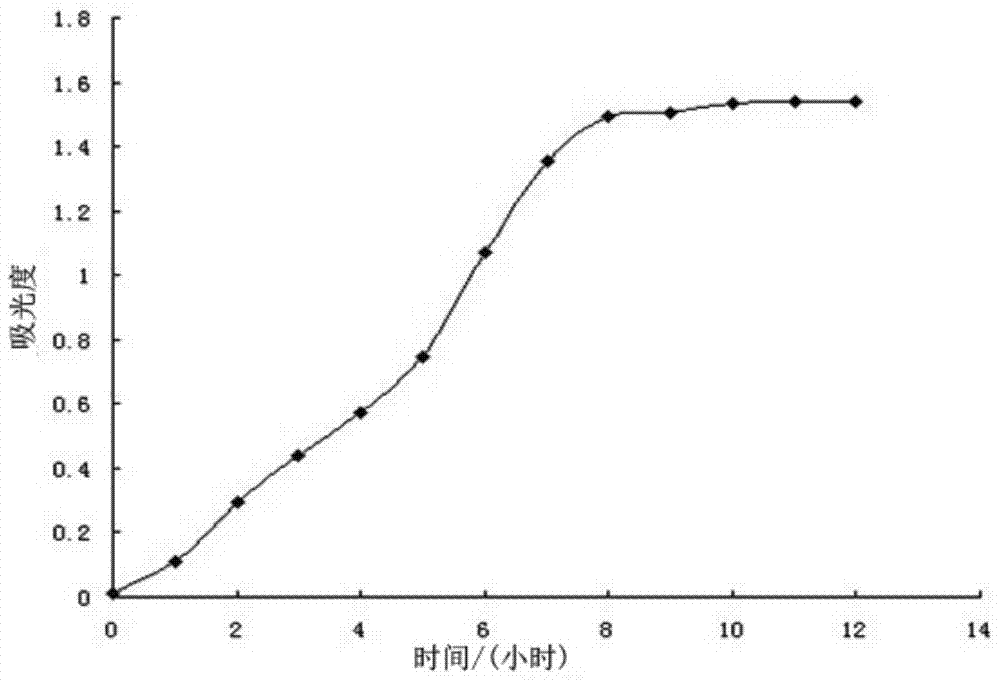

[0040] Weigh 25.0g of deionized water and 0.5g of surfactant in a 100ml small beaker, heat and stir after dissolving, set the temperature at 100°C, add 6.6g of 30% SiO2 drop by drop 2 (Particle size is 10nm) in a small beaker, stir vigorously to make it uniform and form SiO 2 Emulsion: Weigh 0.5mg of Sudan Red III, 0.1mg of petroleum ether with a dissolution range of 90-120°C and 12.6g of sliced paraffin wax with a dissolution range of 52-56°C, stir for 3 minutes to make it uniform; add the paraffin wax mixture to In the silicon dioxide emulsion, after vigorous stirring, the temperature was lowered for processing to form a Pickering emulsion.

[0041] Weigh 3.5g of Pickering emulsion, add 42.0g of industrial-grade silica sol (containing 0.6g of silicon dioxide) and 4.5g of surfactant to further deposit and coat the paraffin particles to form drug sustained-release capsules.

[0042] After 6 hours, it was washed with water and filtered twice, and the powder was dried and col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com