Method for preparing cysteine/polyaniline composite anti-corrosion functional material

A cysteine and functional material technology, which is applied in the field of preparation of cysteine/polyaniline composite anti-corrosion functional materials, can solve the problems of hindering the migration of inhibitors, the anti-corrosion performance needs to be improved, and the polyaniline barrier performance is weakened. , to achieve the effect of improving solubility and dispersibility, improving corrosion protection effect, and improving poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

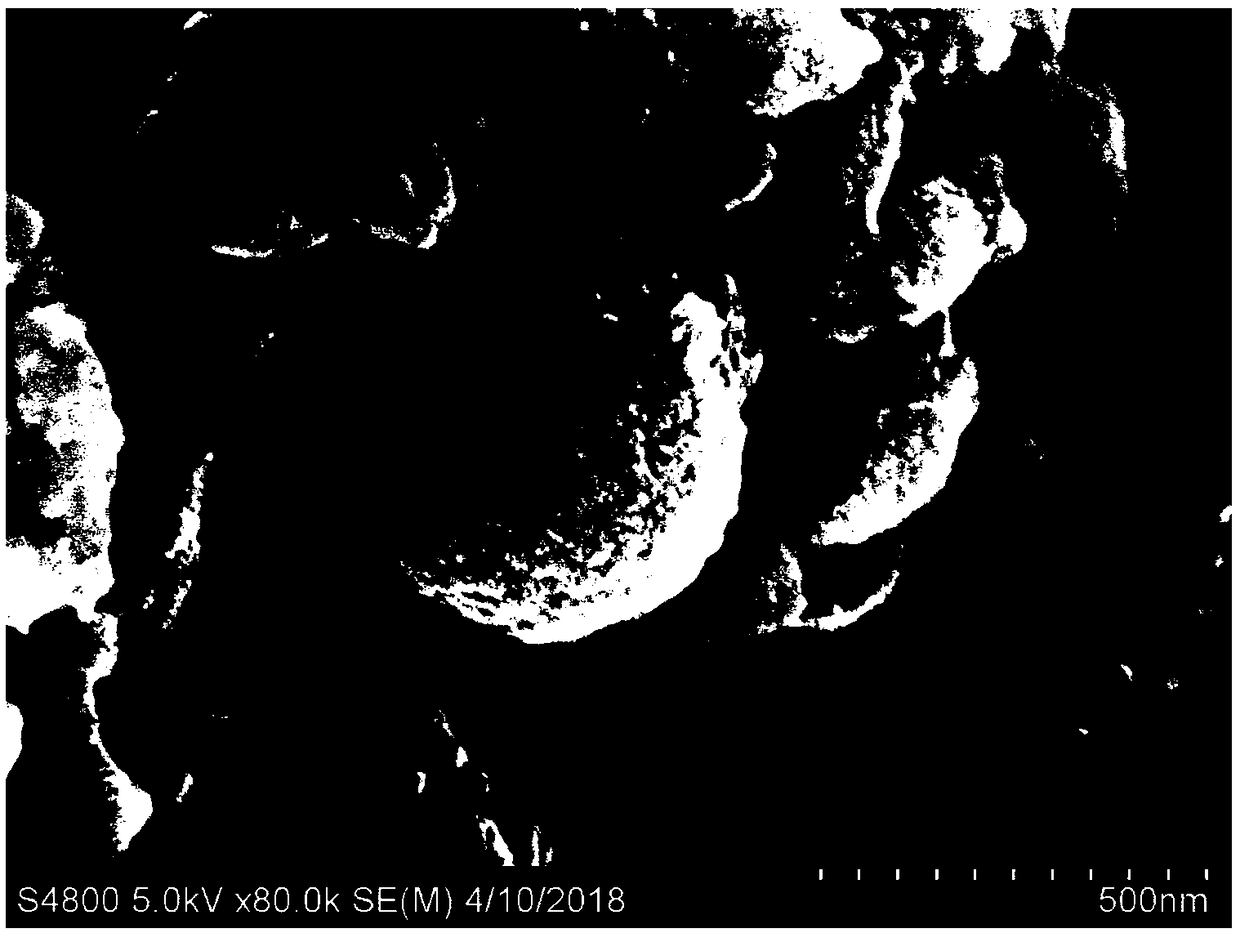

Image

Examples

Embodiment 1

[0028] Measure 0.49mL of aniline and 1.23mL of ethylbenzene respectively, mix and stir evenly, and use this as a hydrophobe, weigh 62.5mg of sodium lauryl sulfate, fully dissolve it in 6ml of deionized water, and use it as an emulsifier, add the emulsifier to the hydrophobic In the mixture, 7.5 mg of cysteine was weighed and added therein as an inhibitor. The mixed solution was fully stirred at room temperature at a stirring speed of 1200 rpm for 70 min, then the mixture was cooled in an ice bath and ultrasonically treated for 300 seconds to emulsify it. Add 15wt% polyvinyl alcohol aqueous solution into the microemulsion, then weigh 1.23g of ammonium persulfate, dissolve it completely in 1.67mL of deionized water, and add it dropwise into the microemulsion at room temperature. After the reaction was completed, it was washed several times with deionized water until the upper layer solution was clear. Centrifuge the above solution in a centrifuge at a high speed of 7000rpm fo...

Embodiment 2

[0031] Measure 0.49mL of aniline and 1.23mL of ethylbenzene respectively, mix and stir evenly, and use this as a hydrophobe, weigh 62.5mg of sodium lauryl sulfate, fully dissolve it in 6ml of deionized water, and use it as an emulsifier, add the emulsifier to the hydrophobic In the mixture, 15 mg of cysteine was weighed and added therein as an inhibitor. The mixed solution was fully stirred at room temperature at a stirring speed of 1200 rpm for 70 min, then the mixture was cooled in an ice bath and ultrasonically treated for 300 seconds to emulsify it. Add 15wt% polyvinyl alcohol aqueous solution into the microemulsion, then weigh 1.23g of ammonium persulfate, dissolve it completely in 1.67mL of deionized water, and add it dropwise into the microemulsion at room temperature. After the reaction was completed, it was washed several times with deionized water until the upper layer solution was clear. Centrifuge the above solution in a centrifuge at a high speed of 7000rpm for...

Embodiment 3

[0034] Measure 0.49mL of aniline and 1.23mL of ethylbenzene respectively, mix and stir evenly, and use this as a hydrophobe, weigh 62.5mg of sodium lauryl sulfate, fully dissolve it in 6ml of deionized water, and use it as an emulsifier, add the emulsifier to the hydrophobic In the mixture, 22.5 mg of cysteine was weighed and added therein as an inhibitor. The mixed solution was fully stirred at room temperature at a stirring speed of 1200 rpm for 70 min, then the mixture was cooled in an ice bath and ultrasonically treated for 300 seconds to emulsify it. Add 15wt% polyvinyl alcohol aqueous solution into the microemulsion, then weigh 1.23g of ammonium persulfate, dissolve it completely in 1.67mL of deionized water, and add it dropwise into the microemulsion at room temperature. After the reaction was completed, it was washed several times with deionized water until the upper layer solution was clear. Centrifuge the above solution in a centrifuge at a high speed of 7000rpm f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com