Rapid preparation method of three-dimensional ordered macroporous titanium dioxide

A titanium dioxide, three-dimensional ordering technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve problems such as incomplete filling, clogged pores on the surface of materials, and problems with the regularity of material morphology, achieving shortened time and simple structure effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

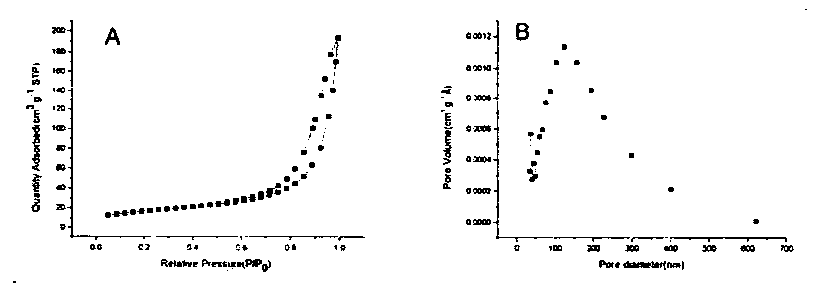

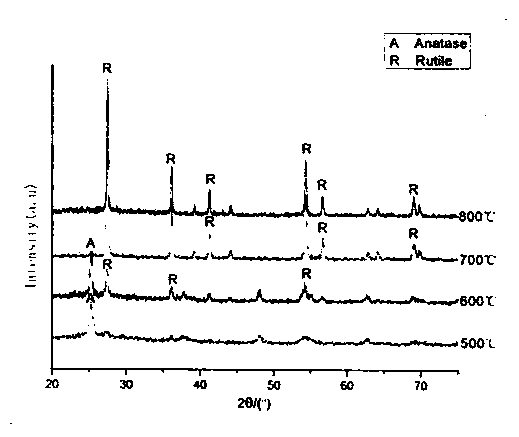

Embodiment 1

[0023] (1) Spread the aqueous solution of monodisperse polystyrene microspheres (particle size: 265nm, dispersion coefficient: 0.005) with a mass fraction of 5% on a clean glass slide, evaporate for 4 hours at a humidity of 40% and a temperature of 60°C to prepare polystyrene microspheres. Styrene colloidal crystal film;

[0024] (2) heat-treat the prepared colloidal crystal film at a temperature of 100°C for 30 minutes, and after cooling to room temperature, cover the surface with a layer of glass slides, and fix the two slides firmly with clips to form a "sandwich " double slide of the structure;

[0025] (3) Mix tetrabutyl titanate and absolute ethanol at a volume ratio of 1:5, and magnetically stir for 2 hours to obtain a uniform and transparent precursor solution;

[0026] (4) Put the double glass slide with "sandwich" structure vertically into the precursor solution, and take it out after keeping the vacuum at -0.07MPa for 1min;

[0027] (5) Put the filled double glass...

Embodiment 2

[0031] (1) Spread the aqueous solution of monodisperse polystyrene microspheres (particle size: 310nm, dispersion coefficient: 0.005) with a mass fraction of 5% on a clean glass slide, evaporate for 4 hours at a humidity of 40% and a temperature of 60°C to prepare polystyrene microspheres. Styrene colloidal crystal film;

[0032] (2) heat-treat the prepared colloidal crystal film at a temperature of 100°C for 30 minutes, and after cooling to room temperature, cover the surface with a layer of glass slides, and fix the two slides firmly with clips to form a "sandwich " double slide of the structure;

[0033] (3) Mix tetrabutyl titanate and absolute ethanol at a volume ratio of 1:10, and stir magnetically for 2 hours to obtain a uniform and transparent precursor solution;

[0034] (4) Put the double glass slide with "sandwich" structure vertically into the precursor solution, and take it out after keeping the vacuum at -0.07MPa for 1min;

[0035] (5) Put the filled double glas...

Embodiment 3

[0039] (1) Spread the aqueous solution of monodisperse polystyrene microspheres (particle size: 345nm, dispersion coefficient: 0.005) with a mass fraction of 5% on a clean glass slide, evaporate for 4 hours at a humidity of 40% and a temperature of 60°C to prepare polystyrene microspheres. Styrene colloidal crystal film;

[0040] (2) heat-treat the prepared colloidal crystal film at a temperature of 100°C for 30 minutes, and after cooling to room temperature, cover the surface with a layer of glass slides, and fix the two slides firmly with clips to form a "sandwich " double slide of the structure;

[0041] (3) Mix tetrabutyl titanate and absolute ethanol at a volume ratio of 1:15, and magnetically stir for 2 hours to obtain a uniform and transparent precursor solution;

[0042] (4) Put the double glass slide with "sandwich" structure vertically into the precursor solution, and take it out after keeping the vacuum at -0.07MPa for 1min;

[0043] (5) Put the filled double glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com