A fast-setting early-strength magnesium phosphate cement without additional retarder

A strong magnesium phosphate and retarder technology, which is applied in the field of building materials, can solve the problems of poor operability, high cost, and high calcination temperature, and achieve the effects of no shrinkage in the later stage, good retarding effect, and high early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The by-product of boron-containing magnesium oxide from salt lake lithium extraction comes from CITIC Guoan Group Corporation. The chemical composition is: MgO content 82.63%, B 2 o 3 Content 4.63%, Na 2 O content 1.24%, Li 2 O content 0.77%, K 2 O content 0.27%, CaO content 0.14%, SiO 2 Content 0.031%, SO 3 Content 0.76%, its main mineral composition is: MgO content 52.25%, Mg 3 B 2 o 6 Content 12.69%, Mg(OH) 2 Content 35.05%.

[0021] The boron-containing magnesium oxide, a by-product of lithium extraction from salt lakes, is calcined at 800°C for 3 hours to obtain sintered magnesia; after mixing 69 parts of sintered magnesia and 31 parts of potassium dihydrogen phosphate, they are ground and passed through a 180-mesh sieve to obtain sintered magnesia. Fast-setting early-strength magnesium phosphate cement with coagulant.

Embodiment 2

[0023] The by-product of boron-containing magnesium oxide from salt lake lithium extraction comes from CITIC Guoan Group Corporation. The chemical composition is: MgO content 82.63%, B 2 o 3 Content 4.63%, Na 2 O content 1.24%, Li 2 O content 0.77%, K 2 O content 0.27%, CaO content 0.14%, SiO 2 Content 0.031%, SO 3 Content 0.76%, its main mineral composition is: MgO content 52.25%, Mg 3 B 2 o 6 Content 12.69%, Mg(OH) 2 Content 35.05%.

[0024] The boron-containing magnesium oxide, a by-product of lithium extraction from salt lakes, is calcined at 1000°C for 3 hours to obtain sintered magnesia; 69 parts of sintered magnesia is mixed with 31 parts of potassium dihydrogen phosphate, ground and passed through a 180-mesh sieve to obtain sintered magnesia without additional retardation fast-setting early-strength magnesium phosphate cement.

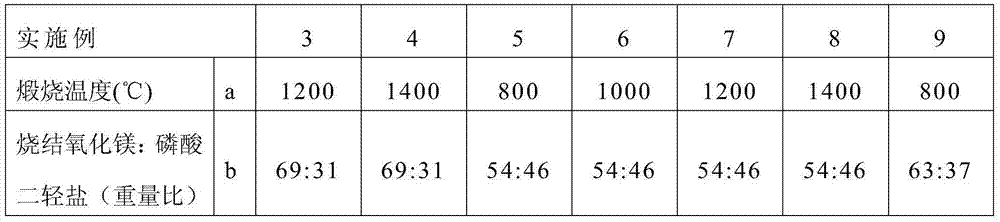

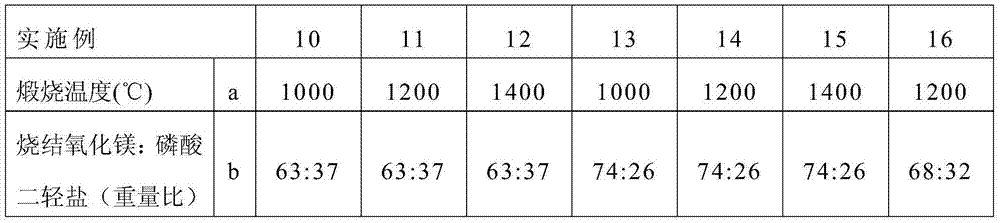

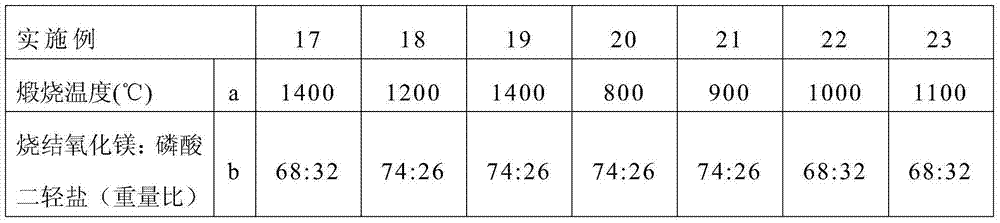

[0025] Table 1 is a list of experimental conditions adopted in Examples 3-36.

[0026] The experimental condition data that table 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com