A method for efficiently separating and enriching tin from nickel-tin-iron alloy waste

A technology for separation, enrichment and ferroalloy, which is applied in the direction of improving process efficiency, can solve problems such as environmental pollution, equipment corrosion, complicated operation, etc., and achieve the effect of high quality, short process and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

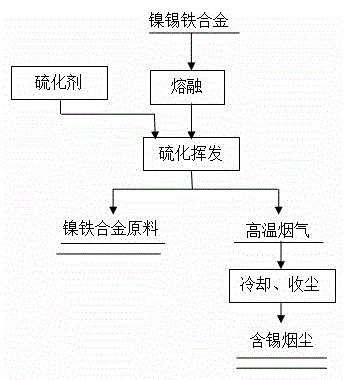

Method used

Image

Examples

Embodiment 1

[0017] Put the nickel-tin-iron alloy scrap (its main chemical composition is (unit: mass fraction): Fe=30, Sn=15, Ni=55) in an electric furnace, heat up to 1550°C, the scrap starts to mix and melt; wait until the scrap is fully melted , Under an inert gas atmosphere with a pressure of 0.1MPa, pyrite is blown into the molten pool at 10% of the mass of the nickel-tin-iron alloy waste through a spray gun to carry out the sulfide detinification reaction. The high-temperature flue gas generated in the process is cooled and recovered Tin-containing smoke and dust.

[0018] After the dust is collected, it is discharged into the atmosphere. After analysis and testing, the tin content in the obtained nickel-iron alloy dropped to 1.8%, and the tin recovery rate reached 88.00%.

Embodiment 2

[0020] Put the nickel-tin-iron alloy scrap (its main chemical composition is (unit: mass fraction): Fe=35, Sn=18, Ni=47) in an electric furnace, heat up to 1570°C, the scrap starts to mix and melt; wait until the scrap is fully melted Under an inert gas atmosphere with a pressure of 1MPa, pyrite and sulfur are blown into the molten pool at 20% of the mass of the nickel-tin-iron alloy waste through a spray gun to carry out the sulfide detinning reaction. The high-temperature flue gas produced in the process is cooled Recover tin-containing smoke and dust.

[0021] After the dust is collected, it is discharged into the atmosphere. After analysis and testing, the tin content in the obtained nickel-iron alloy dropped to 1.1%, and the tin recovery rate reached 92.67%.

Embodiment 3

[0023] Put the nickel-tin-iron alloy scrap (its main chemical composition is (unit: mass fraction): Fe=30, Sn=15, Ni=55) in an intermediate frequency furnace, heat up to 1650°C, the scrap starts to mix and melt; wait until the scrap is fully melted Then, under an inert gas atmosphere with a pressure of 0.5 MPa, nickel sulfide is blown into the molten pool at 25% of the mass of the nickel-tin-iron alloy waste through a spray gun to carry out the sulfide detinning reaction. The high-temperature flue gas generated in the process is cooled and recovered. Tin-containing smoke and dust.

[0024] After the dust is collected, it is discharged into the atmosphere. After analysis and testing, the tin content in the obtained nickel-iron alloy dropped to 0.8%, and the tin recovery rate reached 94.67%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com