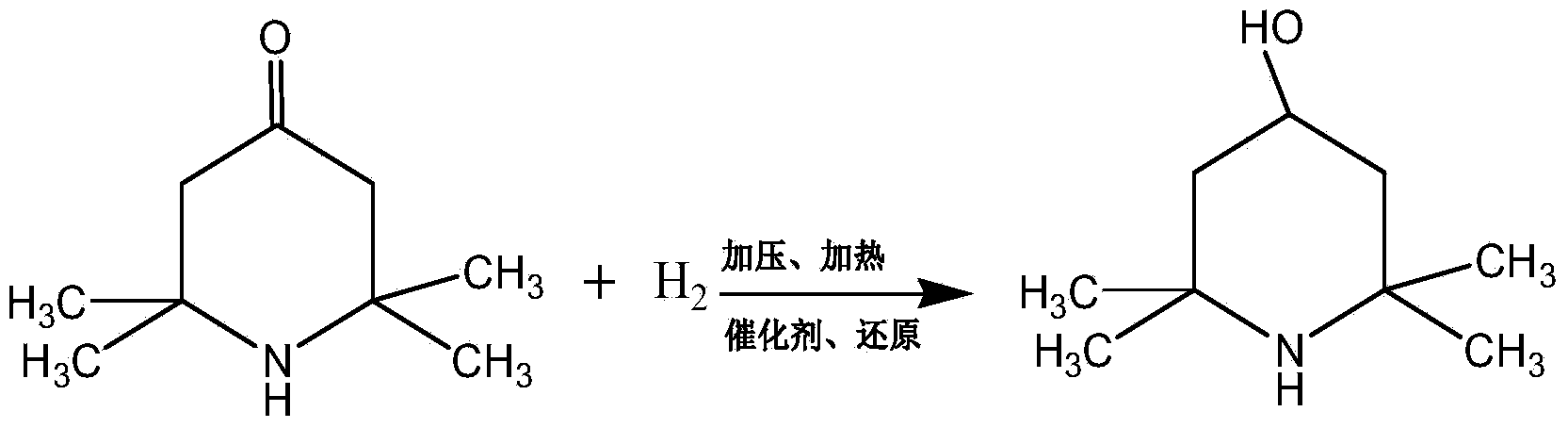

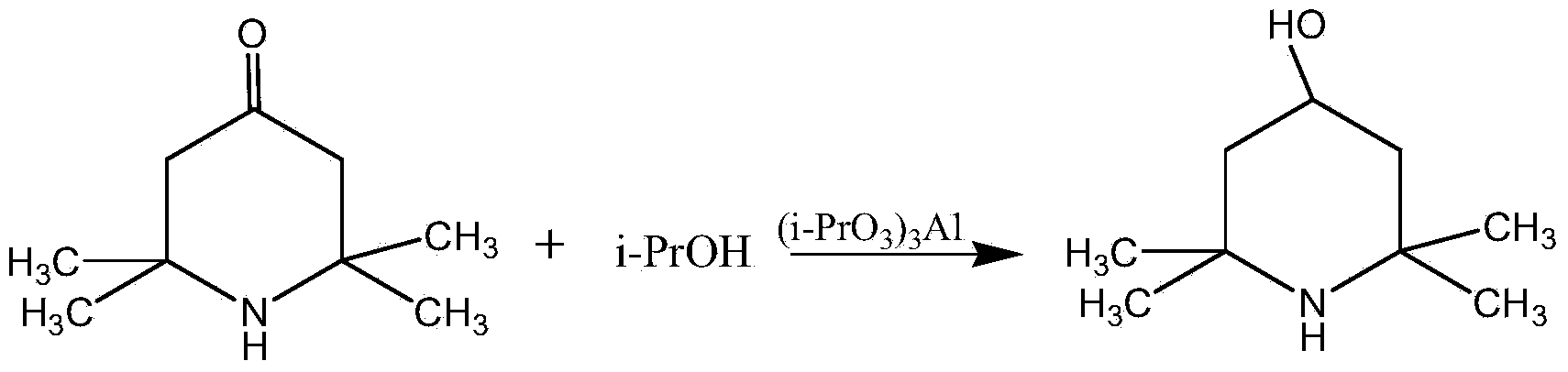

Method for synthesizing pipradrol through electrocatalytic reduction on piperidone by Ti/Ce nano-TiO2 modified electrode

A technology for modifying electrodes and piperidone, which is applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of poor electrode catalytic activity, poor electrode corrosion resistance, low electrolysis efficiency, etc., to achieve increased electrocatalytic sites and corrosion resistance Good, the effect of small surface particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The present embodiment uses Ti / Ce nano-TiO 2 The method for synthesizing piperidinol by electrocatalytic reduction of piperidinone by modified electrode, the steps are:

[0040] Step 1. Preparation of Ti / Ce nano-TiO modified by rare earth Ce doping 2 Modified electrodes. The specific operation steps are:

[0041] 1) Using pure titanium metal as the substrate, the pure titanium metal mentioned here refers to titanium metal with a purity of 99.5-99.7%. Use 600-mesh emery paper to polish the titanium substrate. After the grinding is completed, wash it with acetone and absolute ethanol to remove oil. The volume ratio is 1:4. Finally, it was ultrasonically washed with secondary water and absolute ethanol for 15 minutes, and dried for later use.

[0042] 2) Preparation of rare earth Ce-doped composite nano-TiO 2 Sol, the process is as follows: A solution is a mixed solution composed of butyl titanate, absolute ethanol, acetylacetone, and distilled water. In this example...

Embodiment 2

[0052] The present embodiment uses Ti / Ce nano-TiO 2 The method for synthesizing piperidinol by electrocatalytic reduction of piperidinone by modified electrode, the steps are:

[0053] Step 1. Preparation of Ti / Ce nano-TiO modified by rare earth Ce doping 2 Modified electrodes. The specific operation steps are:

[0054] 1) Using pure titanium metal as the substrate, the pure titanium metal mentioned here refers to titanium metal with a purity of 99.5-99.7%. Use 1000-mesh emery paper to polish the titanium substrate. After the grinding is completed, wash with acetone and absolute ethanol to remove oil. The volume ratio is 1:4. Finally, it was ultrasonically washed with secondary water and absolute ethanol for 10 min, and dried for later use.

[0055] 2) Preparation of rare earth Ce-doped composite nano-TiO 2 Sol, the process is as follows: A solution is a mixed solution composed of butyl titanate, absolute ethanol, acetylacetone, and distilled water. In this example, the ...

Embodiment 3

[0065] The present embodiment uses Ti / Ce nano-TiO 2 The method for the synthesis of piperidinol by electrocatalytic reduction of piperidinone by modified electrode, its basic steps and effects are the same as in Example 1, except that:

[0066] Step 1. Preparation of Ti / Ce nano-TiO modified by rare earth Ce doping 2 In the process of modifying the electrode:

[0067] 1) Use 2000-mesh emery paper to polish the titanium substrate, put the degreased titanium substrate into a mixed solution of HF and ethylene glycol for 20 minutes, and use secondary water and absolute ethanol to ultrasonically wash it for 20 minutes. .

[0068] 2) Preparation of rare earth Ce-doped composite nano-TiO 2 Anhydrous ethanol in the sol process: distilled water: Ce(NO 3 ) 3 .6H 2 The molar ratio of O is 10:0.25:0.7, and the stirring speed of adding solution B to solution A is 600r / min.

[0069] 3) Coat the sol prepared in step 2) on the surface-clean titanium substrate obtained in step 1), dry it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com