Graphene dispersing agent, preparation method thereof and preparation method of graphene

A graphene dispersant and graphene technology, applied in chemical instruments and methods, dyeing low-molecular organic compound treatment, fibrous fillers, etc., can solve the problems of poor dispersion performance and limited dispersed graphene, and achieve excellent graphene Effects of dispersibility, low production cost, and low defect content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

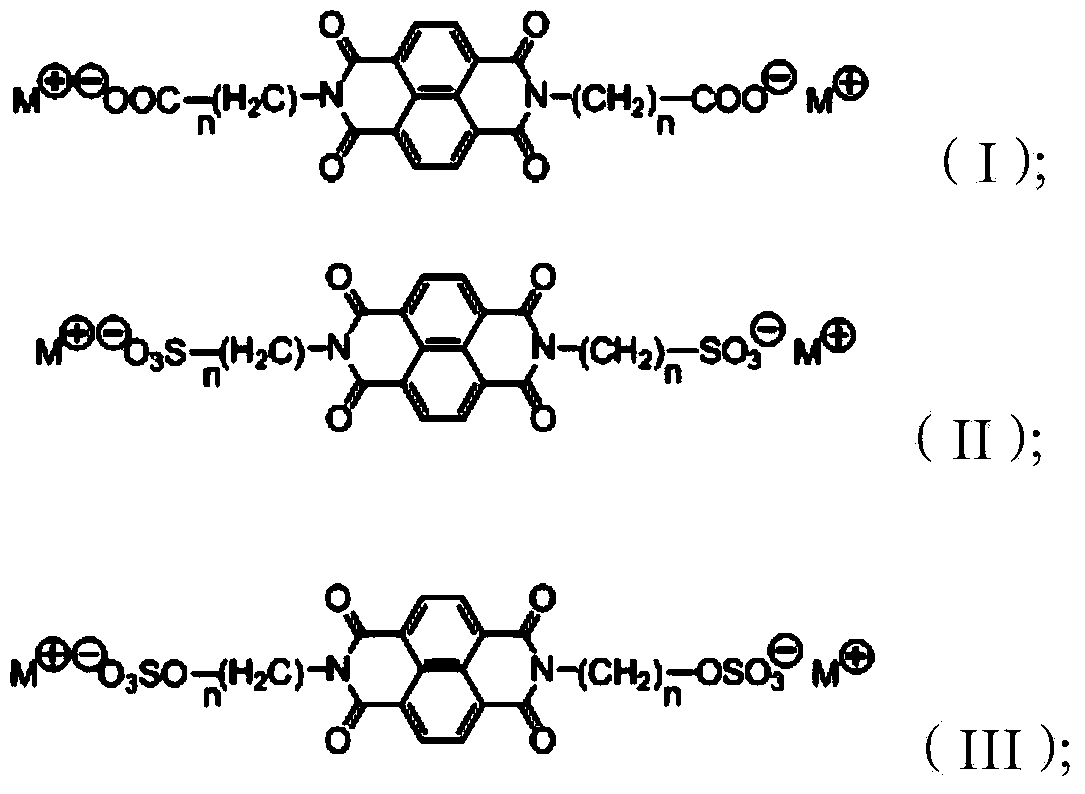

[0037] The invention discloses a preparation method of a graphene dispersant, comprising the following steps:

[0038] Amino organic acid or amino organic acid salt reacts with 1,4,5,8-naphthalene tetracarboxylic dianhydride in an organic solvent to obtain a graphite dispersant as shown in formula (I), formula (II) or formula (III) ;

[0039] The amino organic acid is a compound represented by formula (VII), formula (VIII) or formula (IX);

[0040] The amino acid salt is a compound represented by formula (IV), formula (V) or formula (VI);

[0041]

[0042]

[0043] Among them, n is -CH 2 - the repeating number of the group, n is selected from the integers of 1-20; preferably, n is selected from the integers of 2-18, more preferably, n is selected from the integers of 3-15.

[0044] m + independently selected from H + , alkali metal cation, NH 4 + and any one of the quaternary ammonium salt ions, preferably M + Independently selected from Li + , Na + ,K + and (...

Embodiment 1

[0066] Sodium hydroxide (40.0g, 1.0mmol) was added to an aqueous solution of 3-aminopropionic acid (10mol / L, 100mL), stirred for ten minutes, and the water was distilled off under reduced pressure. The obtained solid was washed once with acetone, and dried in vacuo. 111 g of sodium 3-aminopropionate was obtained. Yield 100%. The reaction equation is as follows:

[0067]

Embodiment 2

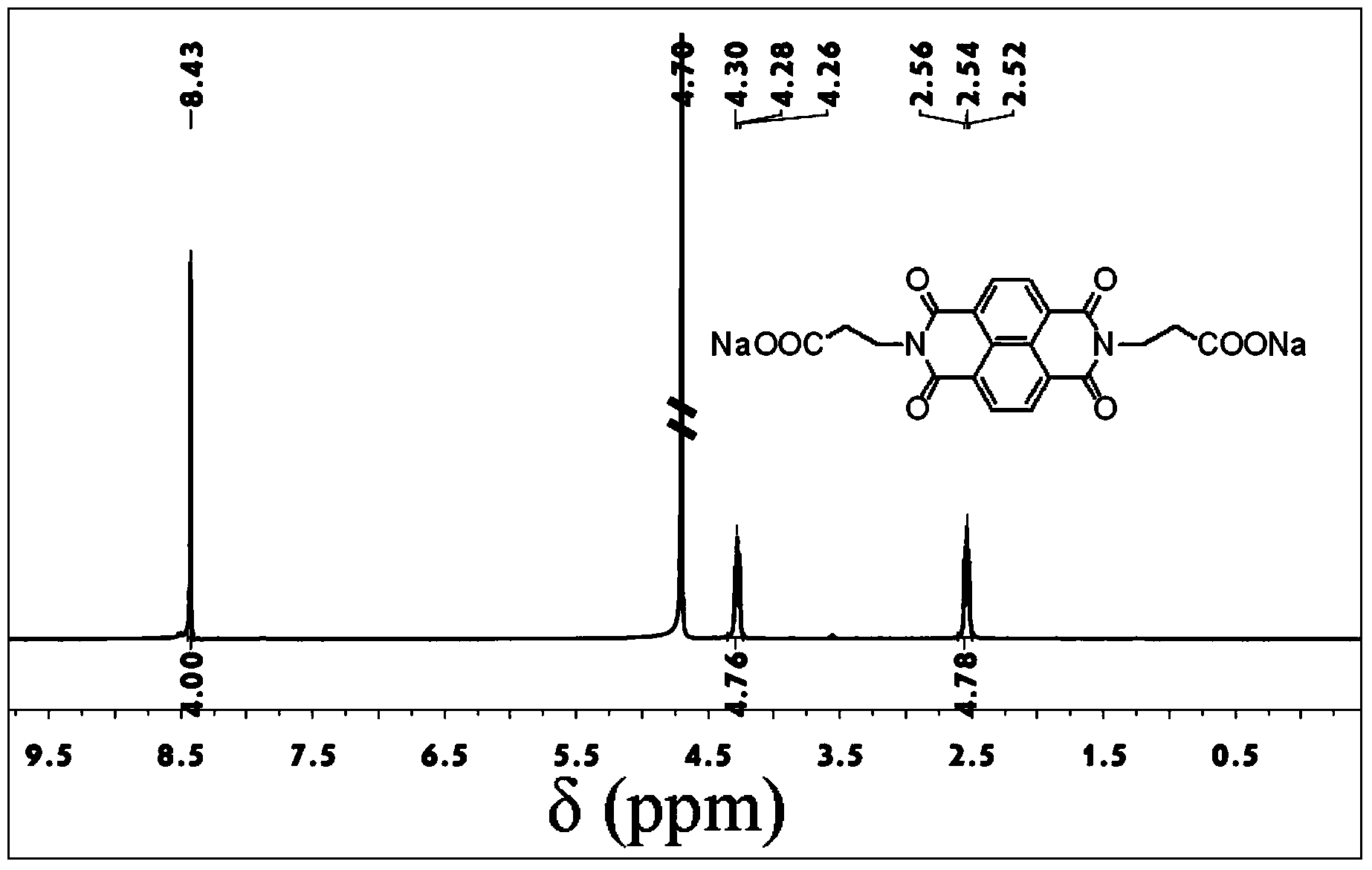

[0069] Add 2.68g1,4,5,8-naphthalene tetracarboxylic dianhydride (10mmol), 3.33g sodium 3-aminopropionate (30mmol) prepared in Example 1 and 50mL N,N-dimethylformamide in the flask , reacted at 100° C. for 10 hours under a nitrogen atmosphere. After cooling, the reaction solution was poured into ether, filtered, and the obtained solid was washed three times with ether to obtain 3,3'-(1,4,5,8-naphthalene tetracarboxylic acid diimide-N,N'-) - Sodium dipropionate 4.36 g. Yield 96%. 1 H NMR (400MHz,D 2 O): δ (ppm) 8.43 (s, 4H), 4.28 (t, 4H), 2.54 (t, 4H). see figure 1 , figure 1 The H NMR spectrum of 3,3'-(1,4,5,8-naphthalene tetracarboxylic acid diimide-N,N'-)-sodium dipropionate prepared in Example 2.

[0070] The reaction equation is as follows:

[0071]

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com