Preparation method of mezlocillin sodium silica gel surface molecularly imprinted polymer

A technology of surface molecular imprinting and mezlocillin sodium, applied in chemical instruments and methods, other chemical processes and other directions, can solve the problems of large diffusion resistance of template molecules, slow mass transfer speed, difficult elution and the like, and achieves low preparation cost, Highly specific and selective, actionable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

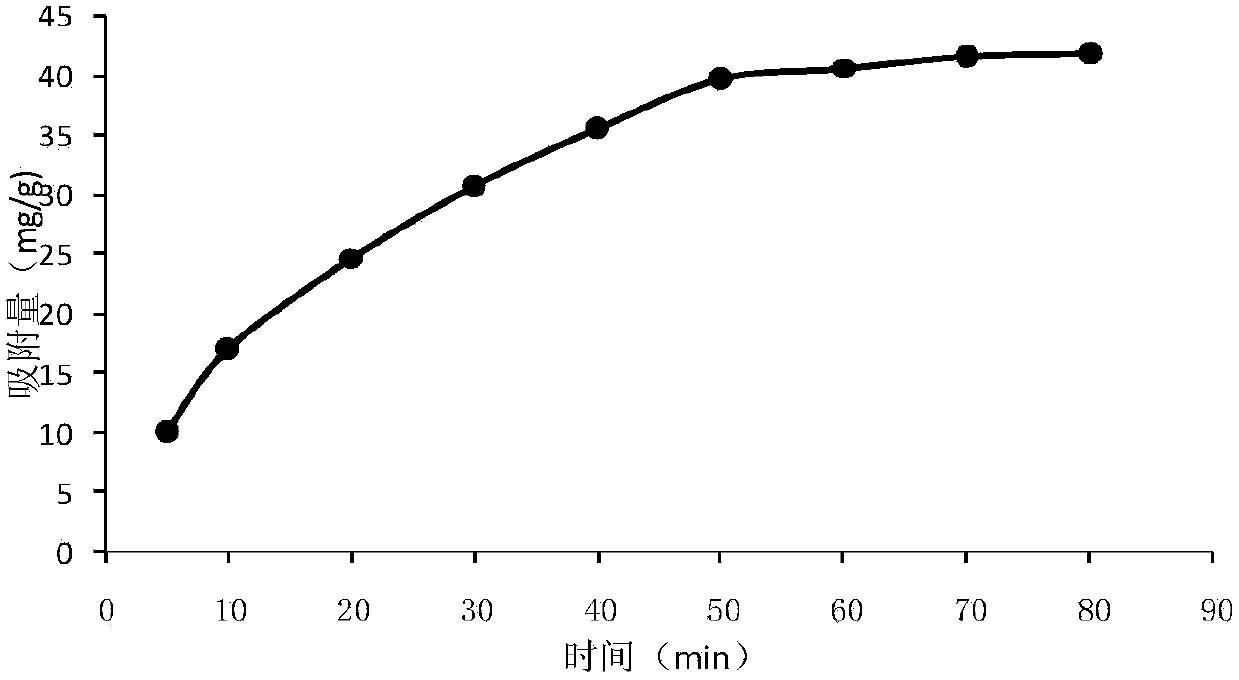

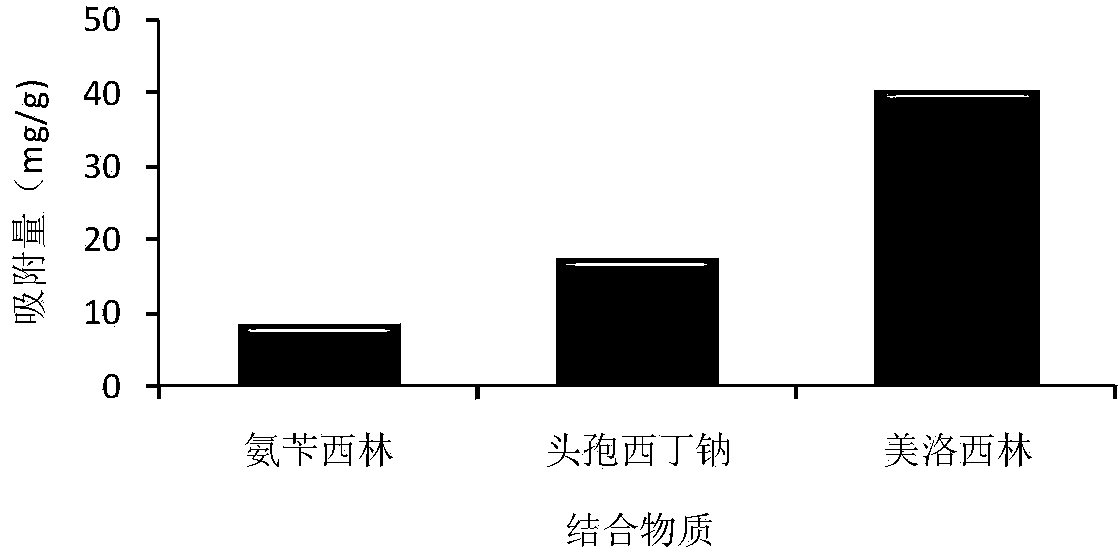

[0023] The preparation method of the molecularly imprinted polymer on the surface of mezlocillin sodium silica gel of the present invention comprises the following steps:

[0024] 1) Activation of silica gel

[0025] Weigh the silica gel and add it to hydrochloric acid, wherein 4-6g silica gel is added to every 10mL of hydrochloric acid; heat and reflux at 90°C-120°C for 12h-36h; filter and wash with triple distilled water until neutral, then dry at 60°C for 24h. Standby; the hydrochloric acid is dilute hydrochloric acid whose volume concentration is 5%-15%.

[0026] 2) Silicone surface modification

[0027] Weigh the activated silica gel and add a mixed solution consisting of toluene, APTES and triethylamine, wherein the volume ratio of toluene, APTES and triethylamine is (50-100):(2-4):1, where every 10mL of the mixed solution corresponds to 2-8g silica gel; the above mixture is heated and refluxed at 110°C for 12h-36h, filtered and washed with methanol, dried at 60°C for ...

Embodiment 1

[0032] Weigh 30g of silica gel, heat and reflux with 250mL of 10% hydrochloric acid at 110°C for 24h to remove a small amount of inorganic impurities in the silica gel and increase the number of hydroxyl groups on the surface of the silica gel. After filtering and washing with triple distilled water until neutral, dry at 60°C for 24 hours. Weigh 10g of activated silica gel and disperse in 100mL of toluene, add 4mLAPTES and 2mL of triethylamine, heat to reflux at 110°C for 24h, wash with a large amount of methanol, dry at 60°C for 24h, and set aside. Weigh 0.5mmol of the template molecule mezlocillin sodium into an Erlenmeyer flask, add 10mL of methanol, 10mL of acetonitrile and 0.5mmol of functional monomer MAA, ultrasonically dissolve, add 2g of modified silica gel and a rotor, seal the mouth of the bottle, and store at 25°C After stirring at constant temperature for about 16 hours, open the bottle stopper, add 238 μL of cross-linking agent EDMA and 0.014 g of initiator AIBN,...

Embodiment 2

[0037] Weigh 20 g of silica gel, heat and reflux with 250 mL of 10% hydrochloric acid at 110°C for 24 hours to remove a small amount of inorganic impurities in the silica gel and increase the number of hydroxyl groups on the surface of the silica gel. After filtering and washing with triple distilled water until neutral, dry at 60°C for 24h. Weigh 10g of activated silica gel and disperse in 100mL of toluene, add 4mLAPTES and 2mL of triethylamine, heat to reflux at 110°C for 24h, wash with a large amount of methanol, dry at 60°C for 24h, and set aside. Weigh 0.5mmol of the template molecule mezlocillin sodium into an Erlenmeyer flask, add 20mL of methanol and 1.0mmol of functional monomer MAA, ultrasonically dissolve, add 2g of modified silica gel and a rotor, seal the bottle mouth, and stir at a constant temperature at 25°C After about 16 hours, open the bottle stopper, add 476 μL of cross-linking agent EDMA and 0.014 g of initiator AIBN, stir ultrasonically for 20 minutes, bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com