Special engineering material for reinforcement and preparing method therefor

An engineering material and special technology, applied in the field of special engineering materials for reinforcement and their preparation, can solve the problems of high reaction temperature and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

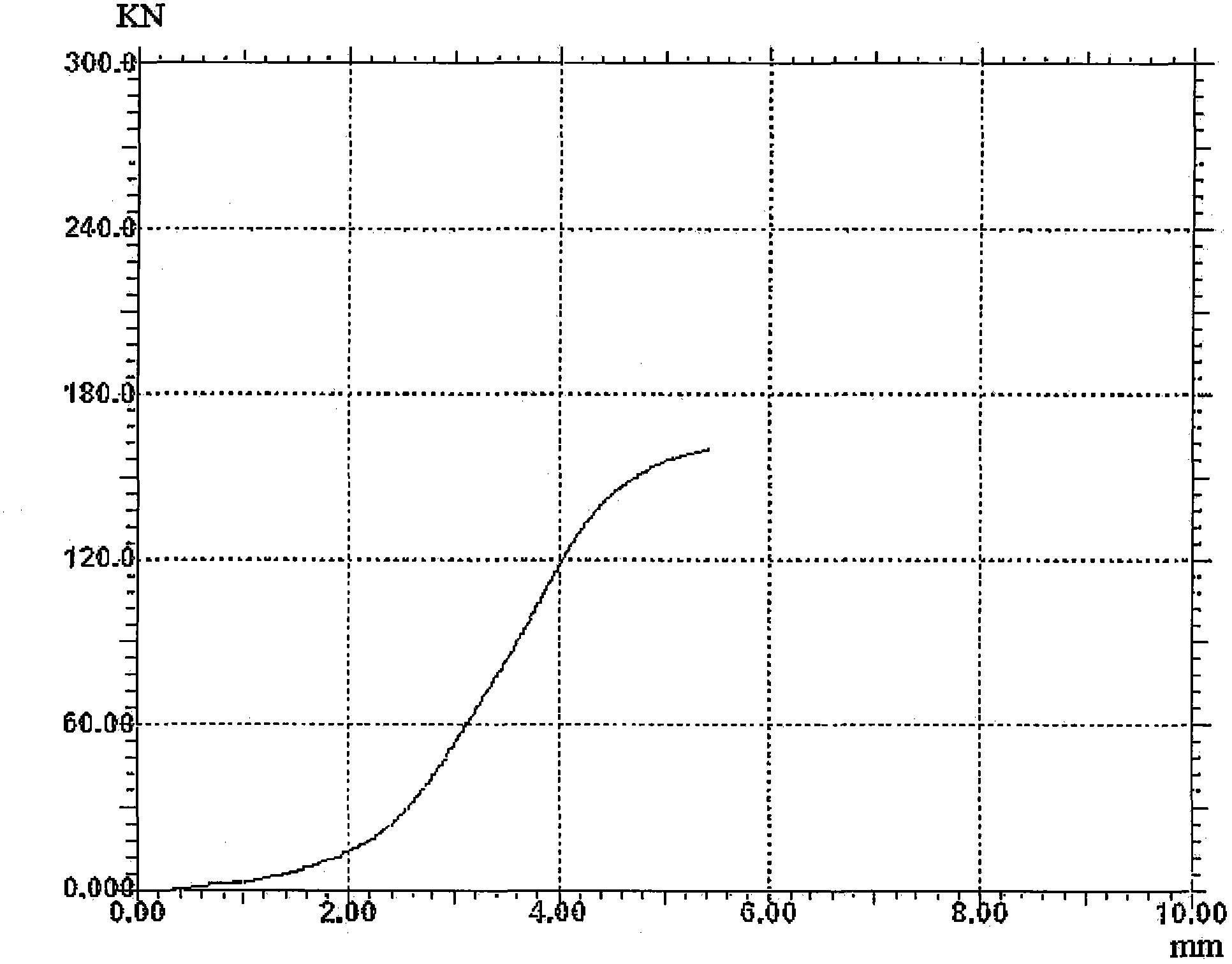

Image

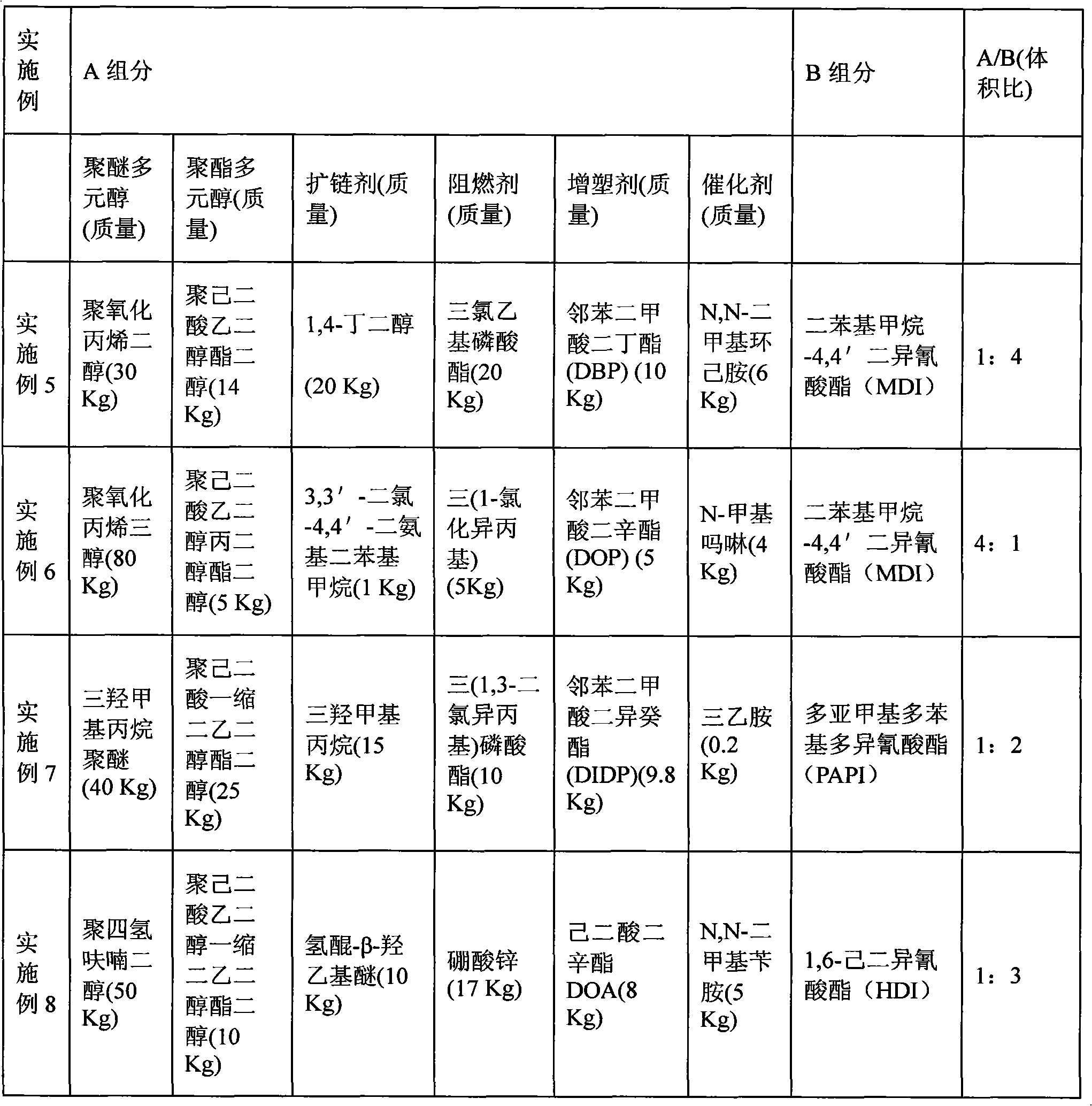

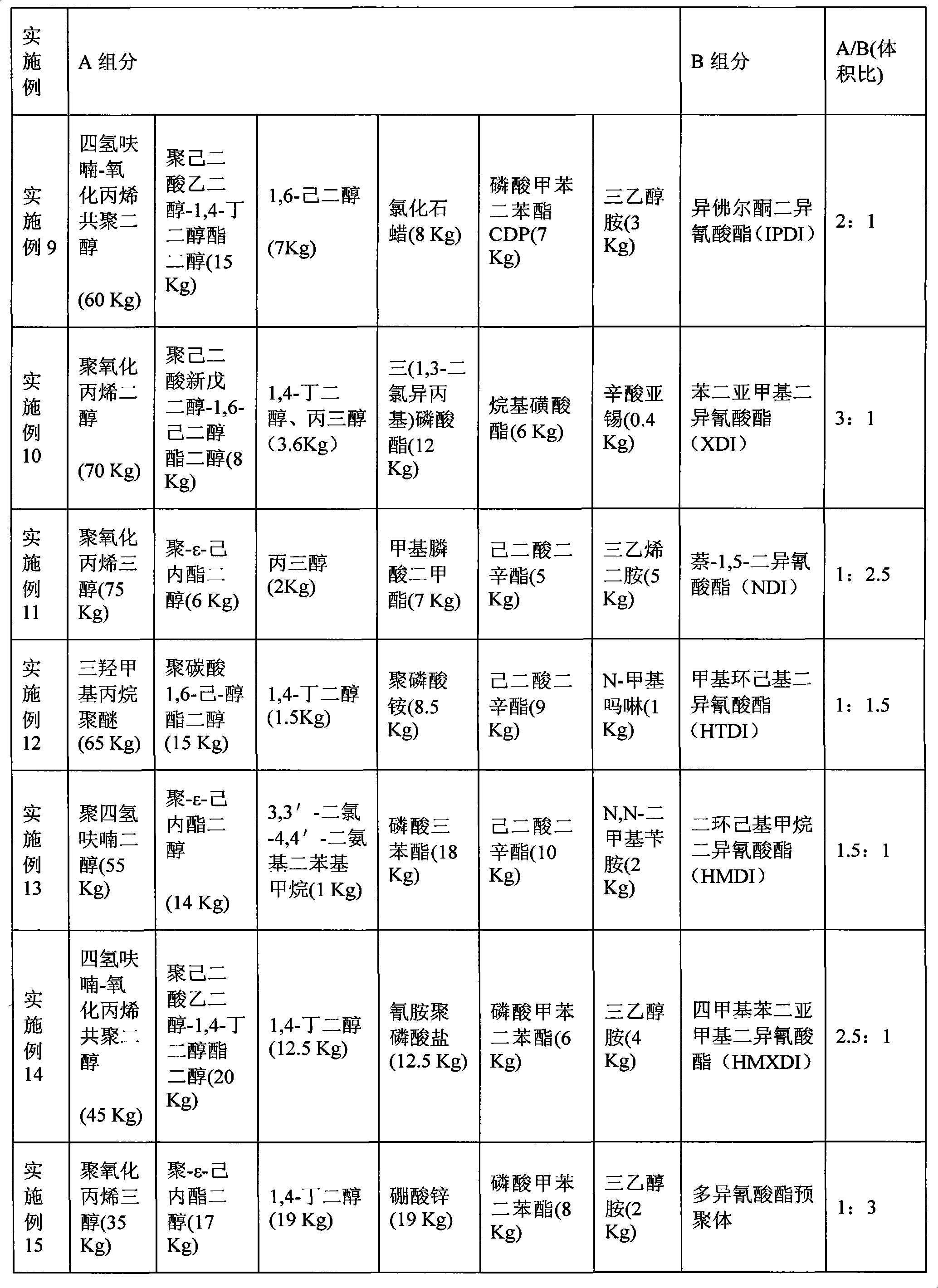

Examples

Embodiment 1

[0057] Component A takes 31Kg of polyoxypropylene diol, 24Kg of polyethylene adipate diol, 19Kg of chain extender 3,3'-dichloro-4,4'-diaminodiphenylmethane, and plasticizer Dioctyl adipate 5.2Kg, flame retardant zinc borate (FB) 19.3Kg, catalyst N, N-dimethylbenzylamine 1.5Kg, weighed polyether polyol, polyester polyol, chain extender Put the agent, plasticizer and flame retardant into the reaction kettle and stir, then add the catalyst and stir fully at room temperature, which is component A.

[0058] B component is toluene diisocyanate.

[0059] Take components A and B and mix them according to the volume ratio of 1:1 to form a consolidated body. Under normal working conditions, its performance indicators are as follows:

[0060] Reaction temperature: 100°C

[0061] Bond strength: 3.1MPa

[0062] Tensile strength: 18MPa

[0063] Compressive strength: 72MPa

[0064] Flame retardancy: Alcohol blowtorch has a flame burning time of 0.16s, a flameless burning time of 3.7s, a...

Embodiment 2

[0066] Component A is polyoxypropylene triol 43Kg, polyethylene adipate propylene glycol ester diol 19Kg, chain extender hydroquinone-β-hydroxyethyl ether 14Kg, plasticizer dioctyl adipate 7.4Kg, Flame retardant zinc borate (FB) 13.7Kg, catalyst N, N-dimethylbenzylamine 2.9Kg, weighed polyether polyol, polyester polyol, chain extender, plasticizer, flame retardant Add it into the reaction kettle and stir, then add the catalyst and stir well at room temperature, which is component A.

[0067] B component is toluene diisocyanate.

[0068] Take components A and B and mix them according to the volume ratio of 2:1 to form a consolidated body. Under normal working conditions, its performance indicators are as follows:

[0069] Reaction temperature: 115°C

[0070] Bond strength: 3.7MPa

[0071] Tensile strength: 23MPa

[0072] Compressive strength: 75MPa

[0073] Flame retardancy: Alcohol blowtorch has a flame burning time of 0.33s, a flameless burning time of 5.2s, an alcohol l...

Embodiment 3

[0075] Component A takes 59Kg of trimethylolpropane polyether, 10Kg of polydiethylene glycol adipate, 8Kg of chain extender hydroquinone-β-hydroxyethyl ether, and 8Kg of plasticizer toluene diphenyl phosphate 8.9Kg, flame retardant chlorinated paraffin 9.5Kg, catalyst N-methylmorpholine 4.6Kg, add the weighed polyether polyol, polyester polyol, chain extender, plasticizer, flame retardant to Stir in the reaction kettle, then add the catalyst and stir fully at room temperature, which is component A.

[0076] B component is toluene diisocyanate.

[0077] Take components A and B and mix them according to the volume ratio of 1:2 to form a consolidated body. Under normal working conditions, its performance indicators are as follows:

[0078] Reaction temperature: 127°C

[0079] Bond strength: 5.8MPa

[0080] Tensile strength: 29MPa

[0081] Compressive strength: 81MPa

[0082] Flame retardancy: Alcohol blowtorch has a flame burning time of 0.65s, a flameless burning time of 7....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com