A kind of fatigue-resistant, high-glow wire performance halogen-free flame-retardant reinforced polyamide composite material and its preparation method and application

A thermoplastic polyamide and high glow wire technology, applied in the field of polyamide composite materials, can solve problems such as fatigue strength research, and achieve the effects of improving fatigue strength, improving glow wire performance, and high fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

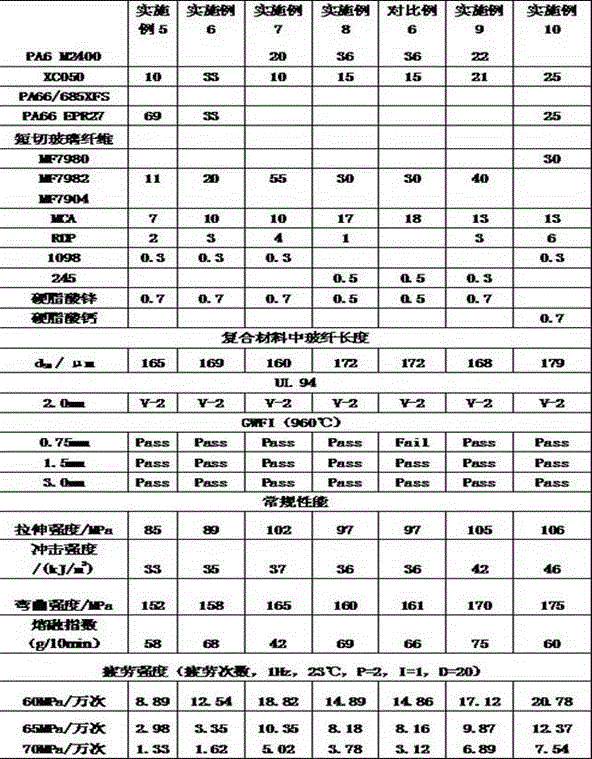

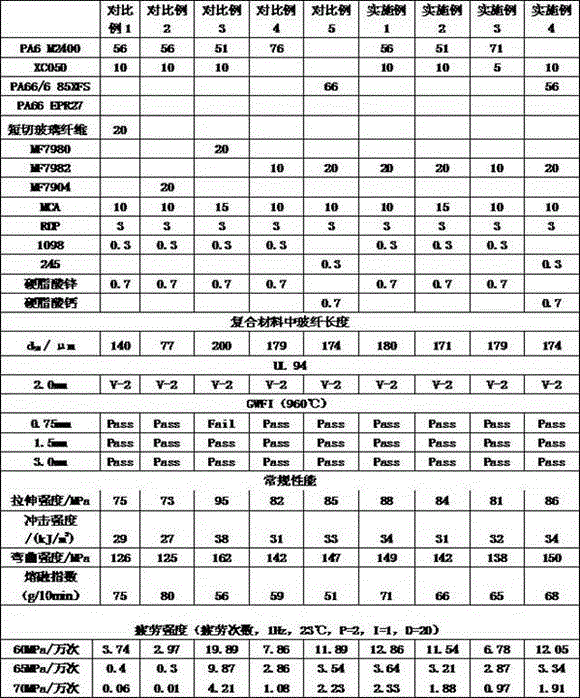

[0060] According to the formula and content shown in Tables 1 and 2, polyamide, halogen-free flame retardant, antioxidant, and lubricant were added into the high-mixer, stirred evenly at room temperature, put into the twin-screw extruder, and ground The crushed glass fiber is fed from the side feeder of the twin-screw extruder, and then extruded and granulated; the temperature of each section of the extruder is respectively: the temperature of the first zone is 210°C, the temperature of the second zone is 220°C, and the temperature of the third zone The temperature is 230°C, the temperature in the fourth zone is 240°C, the temperature in the fifth zone is 250°C, the temperature in the sixth zone is 250°C, the temperature in the seventh zone is 245°C, the temperature in the eighth zone is 240°C, the temperature in the ninth zone is 240°C, the temperature of the machine head is 230°C, the speed of the main engine is 350rpm, The vacuum degree is -0.08~-0.06MPa, and then the materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com