A kind of printed circuit board cleaning agent and using method thereof

A technology for printed circuit boards and cleaning agents, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, detergent compounding agents, etc., can solve the problem of affecting the welding effect of printed circuit boards, unfavorable large-scale promotion and application, and improving enterprise Production costs and other issues, to achieve the effect of cleaning printed circuit boards, improving the pass rate and gold wire tensile test pass rate, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

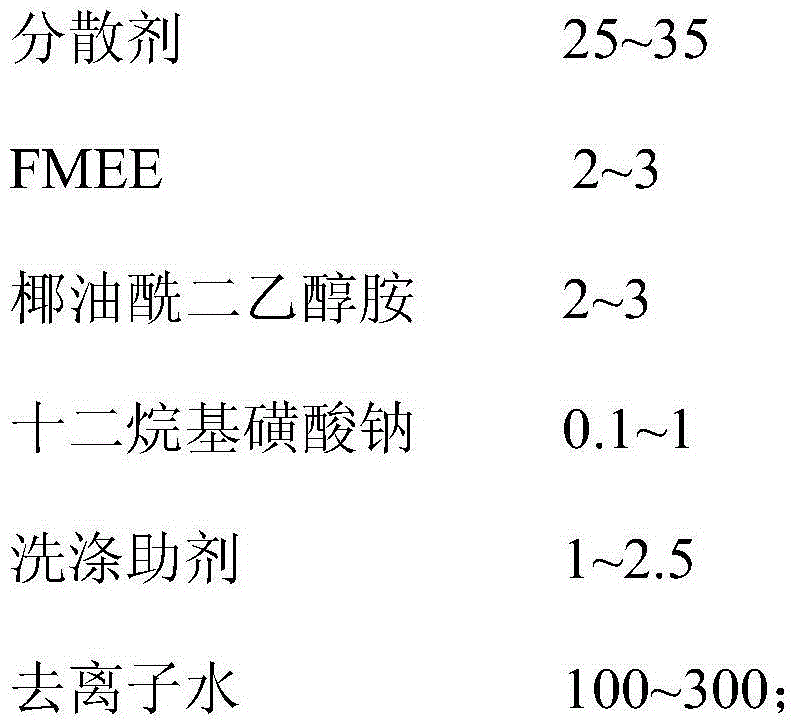

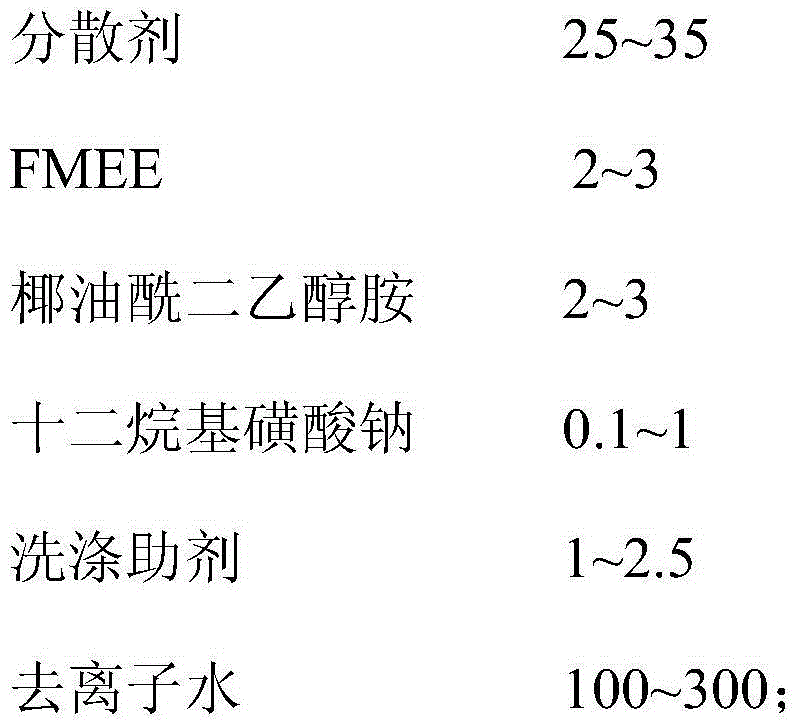

Embodiment 1

[0019] The preparation method of the cleaning agent of the present embodiment is as follows: Weigh 300g dipropylene glycol methyl ether, 26gFMEE, 26g cocoamide diethanolamine, 5g sodium laurylsulfonate, 5g sodium carbonate, 5g sodium silicate, 1700g deionized water , Mix the components evenly under normal temperature and pressure to obtain the printed circuit board cleaning agent.

[0020] In addition to using this cleaning agent in the conventional method, the following method can also be used to clean the printed circuit board to achieve better cleaning effect: add the above printed circuit board cleaning agent into the ultrasonic cleaning machine, and then put the printed circuit board Put into an ultrasonic cleaning machine for cleaning, the power of the ultrasonic cleaning machine is preferably 0.5-0.7KW, the cleaning time is 10min, and the cleaning temperature is 35-40°C, and the printed circuit board after cleaning is dried and set aside.

[0021] The processed printed ...

Embodiment 2

[0023] The preparation method and usage method of this embodiment are the same as in Example 1, the difference is that its components and contents are: dipropylene glycol methyl ether 300g, FMEE 32.6g, cocoamide diethanolamine 26g, sodium laurylsulfonate 5g, Sodium carbonate 6.4g, sodium silicate 5g, deionized water 1700g.

[0024] The binding test is carried out on the processed printed circuit board, the qualification rate of the first welding and the second welding is 100%, and the qualification rate of the gold wire pulling test is 70%.

Embodiment 3

[0026] The preparation method and usage method of this embodiment are the same as in Example 1, the difference is that its components and content are: 30g of dipropylene glycol methyl ether, 2g of FMEE, 2.5g of cocoamide diethanolamine, 0.5g of sodium laurylsulfonate , sodium carbonate 1g, sodium silicate 0.5g, deionized water 170g.

[0027] The binding test was carried out on the processed printed circuit board, the qualification rate of the first welding and the second welding was 100%, and the qualification rate of the gold wire pulling test was 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com