Heavy-current high-frequency plane inductor and making method thereof

A technology of planar inductors and manufacturing methods, applied in the direction of inductor/transformer/magnet manufacturing, transformer/inductor core, transformer/inductor coil/winding/connection, etc., can solve the design and production of high-current and high-frequency planar inductors Difficulties and other problems to achieve the effect of ensuring flattening, increasing heat dissipation area and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

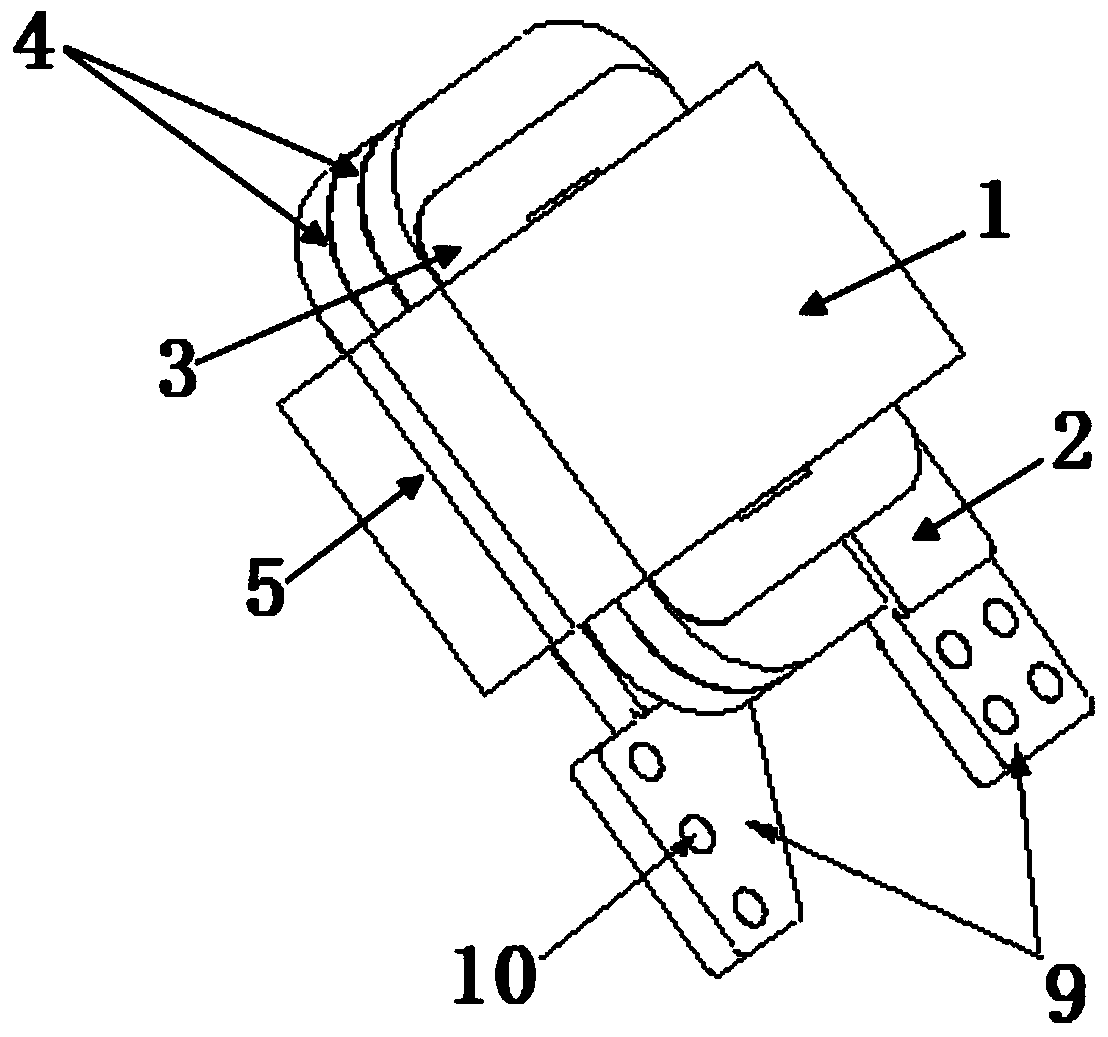

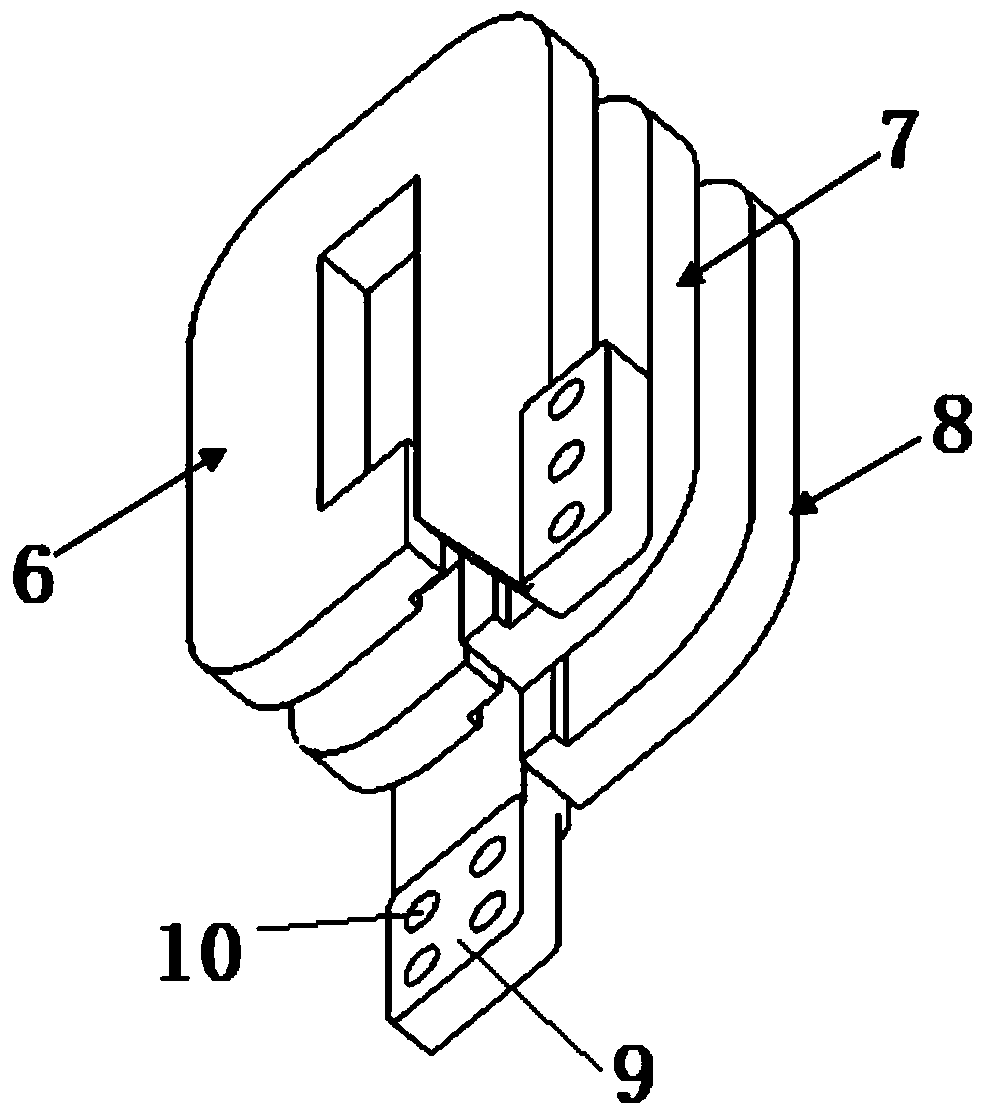

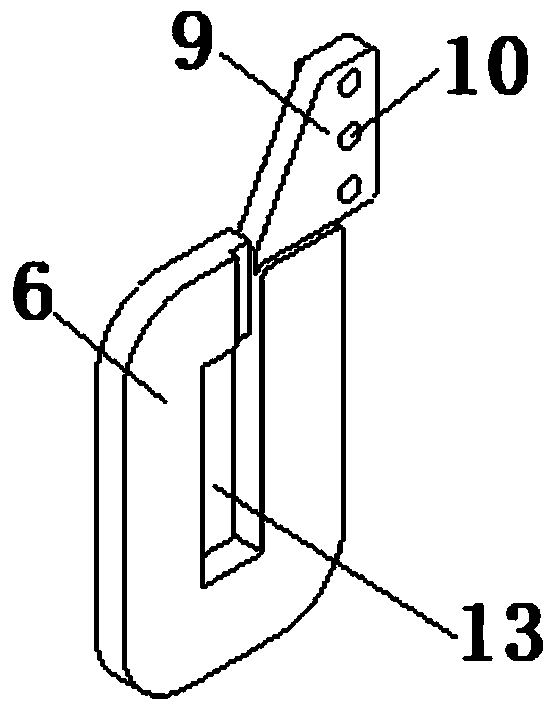

[0037] Such as Figure 1 to Figure 8 As shown, the high-current high-frequency planar inductor includes a coil 2 and a magnetic core 1 arranged outside the coil 2 , and an insulating sheet is provided between the coil 2 and the magnetic core 1 .

[0038] The coil 2 comprises a single-turn coil 7 and a start coil 6 and an end coil 8 arranged on both sides of the single-turn coil 7, a first insulating sheet 4 is arranged between the single-turn coil 7 and the start coil 6, and the single-turn coil A first insulating sheet 4 is also provided between 7 and the end coil 8; a second insulating sheet 3 is provided between the starting coil 6 and the magnetic core 1, and a second insulating sheet 3 is also provided between the end coil 8 and the magnetic core 1. Two insulating sheets 3 . An insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com