Preparation method for cobaltosic oxide-graphene composite material and preparation method for lithium ion battery

A technology of tricobalt tetroxide and lithium-ion batteries, which is applied in the manufacture of electrolyte batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of poor rate characteristics and cycle performance, and achieve the effect of improving cycle performance and rate characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

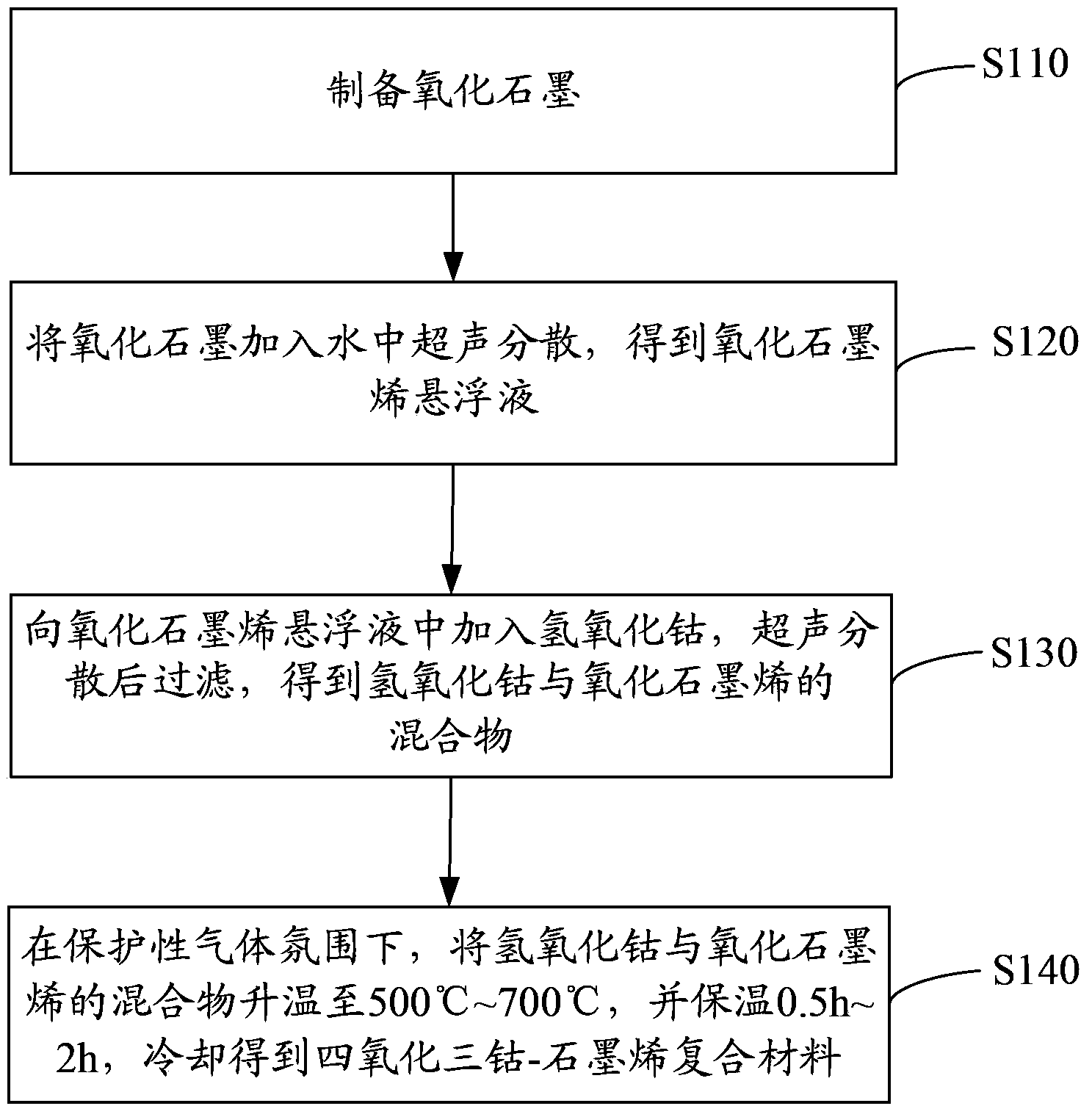

[0030] see figure 1 , the preparation method of the tricobalt tetroxide-graphene composite material of one embodiment, comprises the steps:

[0031] Step S110, preparing graphite oxide.

[0032] Preparation of graphite oxide comprises the following steps:

[0033] Step 1. Add graphite into the mixed acid solution composed of concentrated sulfuric acid and concentrated nitric acid to form a mixed solution, keep the temperature of the mixed solution at -2°C~2°C and stir for 10min~30min.

[0034] Preferably, the purity of graphite is 99.5%. Graphite is a powder with a particle size in the order of microns.

[0035] Preferably, the solid-to-liquid ratio of graphite to concentrated sulfuric acid and concentrated nitric acid is 1g:(85ml~95ml):(24ml~25ml).

[0036] Preferably, the mixed solution is placed in an ice-water bath and stirred for 20 minutes.

[0037] Preferably, the mass concentration of concentrated nitric acid is 98%, and the mass concentration of concentrated nitr...

Embodiment 1

[0076] This embodiment prepares the technological process of tricobalt tetroxide-graphene composite material as follows:

[0077] Graphite→graphite oxide→cobalt hydroxide / graphene oxide→cobalt tetroxide-graphene composite

[0078] (1) Graphite: 99.5% purity;

[0079] (2) Graphite oxide: Weigh 1g of graphite with a purity of 99.5% in (1) and add it to a mixed solution consisting of 90ml of concentrated sulfuric acid (98% by mass fraction) and 25ml of concentrated nitric acid (65% by mass fraction). Stir in an ice-water mixed bath environment for 20 minutes, then slowly add 6g of potassium permanganate to the mixture, stir for 1 hour, then heat the mixture to 85°C and keep it for 30 minutes, then add 92ml of deionized water to continue Keep at 85°C for 30 minutes, finally add 10ml of hydrogen peroxide solution (mass fraction 30%), stir for 10 minutes, filter the mixture with suction, and then wash the solids with 100ml of dilute hydrochloric acid and 150ml of deionized water re...

Embodiment 2

[0083] This embodiment prepares the technological process of tricobalt tetroxide-graphene composite material as follows:

[0084] Graphite→graphite oxide→cobalt hydroxide / graphene oxide→cobalt tetroxide-graphene composite

[0085] (1) Graphite: 99.5% purity;

[0086] (2) Graphite oxide: Weigh 1g of graphite with a purity of 99.5% in (1) and add it to a mixed solution consisting of 90ml of concentrated sulfuric acid (98% by mass fraction) and 25ml of concentrated nitric acid (65% by mass fraction). Stir in an ice-water mixed bath environment for 20 minutes, then slowly add 6g of potassium permanganate to the mixture, stir for 1 hour, then heat the mixture to 85°C and keep it for 30 minutes, then add 92ml of deionized water to continue Keep at 85°C for 30 minutes, finally add 10ml of hydrogen peroxide solution (mass fraction 30%), stir for 10 minutes, filter the mixture with suction, and then wash the solids with 100ml of dilute hydrochloric acid and 150ml of deionized water re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com