Drying agent with mildew-proof effect and preparation method thereof

A desiccant and anti-fungal agent technology, applied in the direction of separation methods, anti-rot containers, chemical instruments and methods, etc., can solve the problems affecting the quality of storage equipment, the health of warehouse workers, poor mold inhibition, etc., and achieve obvious dehumidification effect, improvement of health level, effect of significant function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

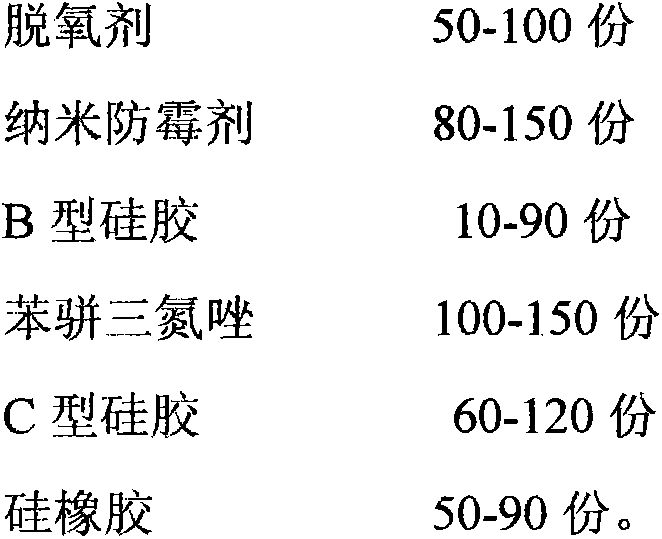

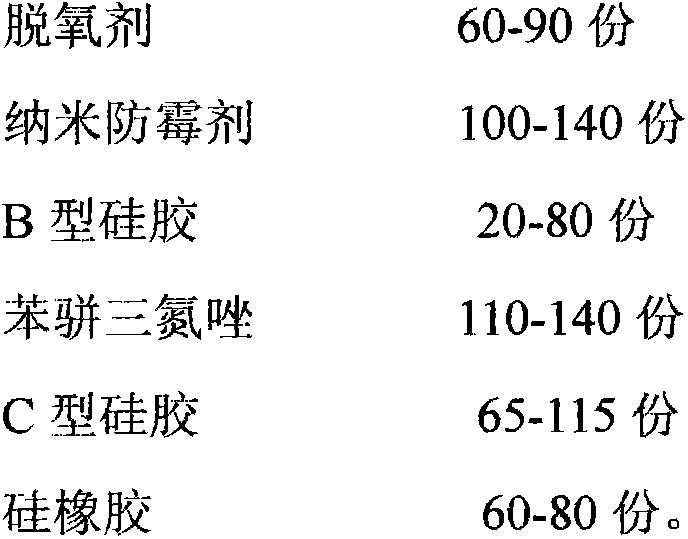

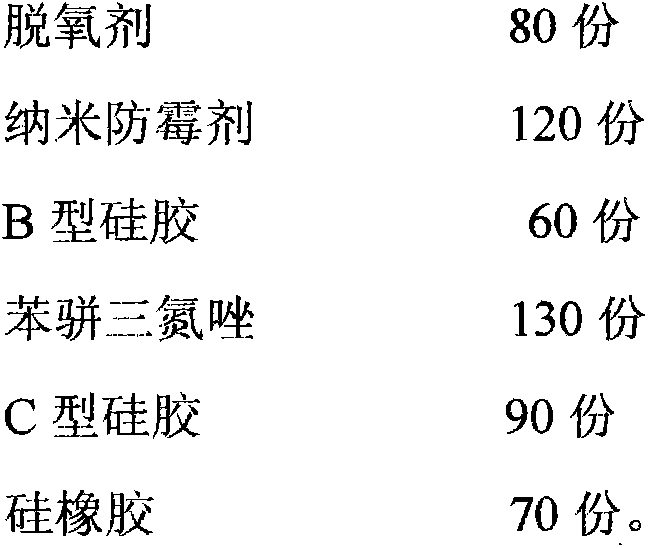

[0042] The preparation of embodiment 1 anti-mildew function desiccant

[0043]

[0044]

[0045] The preparation method of desiccant 1:

[0046] The first step, the preparation of desiccant base material:

[0047] 1) Put B-type silica gel (pore volume ≥ 0.7ml / g), sulfur rubber, and silicic acid gel in a high-speed pulse melting machine for centrifugal melting. The temperature is kept at 90°C, pH=7.0, and the speed is 30 rpm / Minutes, the time is kept for 70 minutes;

[0048]2) Add nano silicon dioxide, control the temperature at 90°C for 70 minutes at this moment, then quickly drop to 30°C and keep for 70 minutes.

[0049] The second step is the synthesis of desiccant products:

[0050] Add nano-zinc to the prepared solid, organically dissolve at 210°C, pass through a 500-mesh filter sieve for primary screening, and then pass through a 900-mesh filter sieve for re-screening, observe the color change of the liquid, and add benzotriazepam when it becomes transparent az...

Embodiment 2

[0085] Desiccant and dehumidification effect experiment of embodiment 2 desiccant (average sampling 3 times)

[0086] A warehouse in Sanya, ℃=28, r≥85%, 98000m 3 , severe mildew, 1000cm 3 There are more than 1,200 mold spores, and the packaging materials and equipment have been stored in the warehouse for more than 7 days. The quarantine found that the density of mold spores on the surface of the equipment was 9.6 hundred / 10cm 2 , the mold spore density on the surface of aluminum-plastic packaging is 6.6 hundred / 10cm 2 , when sealing and packaging:

[0087] (1) Desiccant (desiccant 1 in Example 1) with anti-mildew function is used in the aluminum-plastic packaging bag

[0088] Dosage: 10mL / 1000cm 3 , after 28 days, the mold spore density on the surface of the equipment is 0.07 hundred / 10cm 2 , the mold spore density on the surface of aluminum-plastic packaging is 0.05 hundred / 10cm 2 , in line with precision instrument storage requirements.

[0089] (2) Ordinary desiccan...

Embodiment 3

[0091] Desiccant and dehumidification effect experiment of embodiment 3 desiccant (average sampling 3 times)

[0092] A warehouse in Ningbo, ℃=28, r≥85%, 120000m 3 ,, severe mildew, 1000cm 3 There are more than 9,500 mold spores, and the packaging materials and equipment have been stored in the warehouse for more than 7 days. The quarantine found that the density of mold spores on the surface of the equipment was 11.4 hundred / 10cm 2 , the mold spore density on the surface of aluminum-plastic packaging is 8.9 hundred / 10cm 2 , when sealing and packaging:

[0093] (1) Use desiccant with anti-mold function (anti-mold agent 2 in embodiment 1) in the aluminum-plastic packaging bag

[0094] Dosage: 10mL / 1000cm 3 , after 28 days, the mold spore density on the surface of the equipment is 0.09 hundred / 10cm 2 , the mold spore density on the surface of aluminum-plastic packaging is 0.07 hundred / 10cm 2 , in line with precision instrument storage requirements.

[0095] (2) Ordinary d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com