Hydrogenation catalyst carrier for coal liquefaction oil, catalyst as well as preparation method and application of hydrogenation catalyst carrier

A technology of hydrogenation catalyst and catalyst carrier, which is applied in the direction of catalyst carrier, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., and can solve the problem that the active components are easy to aggregate and grow, and it is difficult to large-scale industrialization , Catalyst activity reduction and other issues, to achieve excellent electron transfer performance, improve mechanical strength, the effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

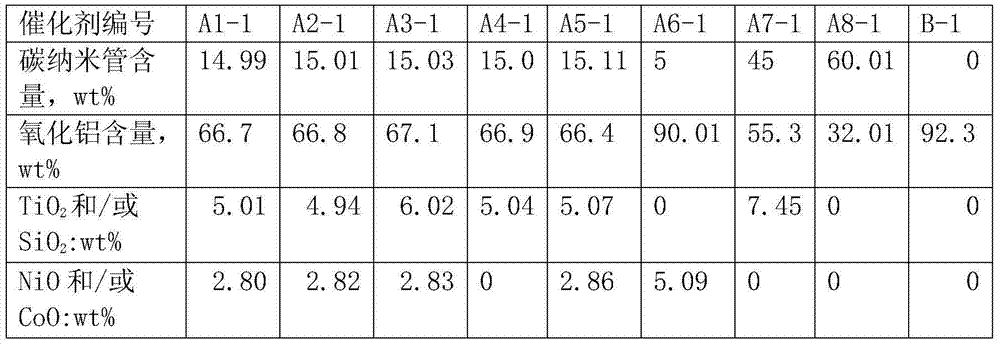

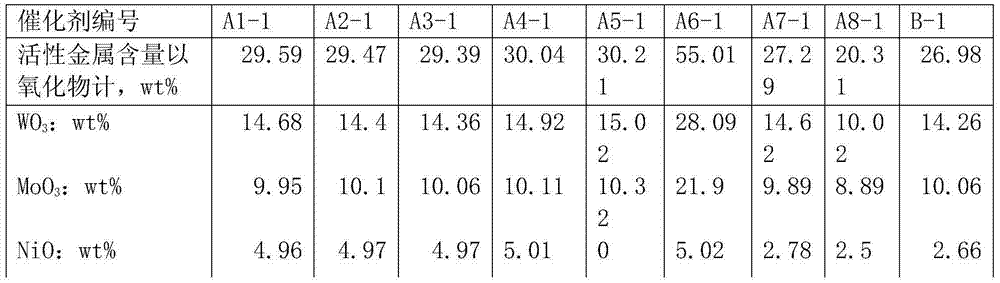

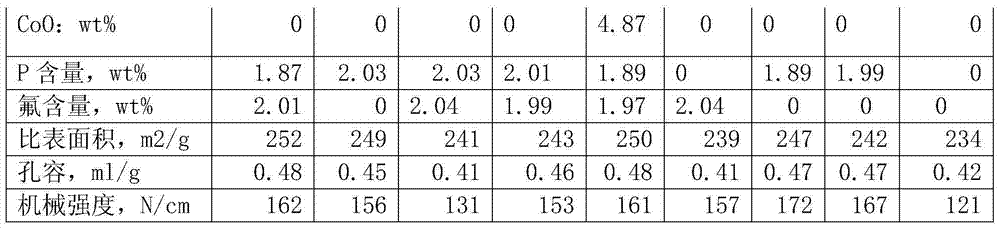

Examples

Embodiment 1

[0034] Preparation of catalyst support:

[0035] Dissolve nickel nitrate in ethanol, configure it as nickel oxide, 15g NiO / 100ml ethanol solution, spray and impregnate the prepared solution into 80g carbon nanotubes, place it at room temperature to air dry, and put it in a vacuum oven at a temperature of 80°C Dry under N for 4 hours in a muffle furnace 2 Calcining at 350° C. under the atmosphere for 4 hours to obtain nickel oxide-loaded carbon nanotubes, the nickel-containing carbon nanotubes mentioned in the following steps are the nickel oxide-loaded carbon nanotubes;

[0036] 200g alumina powder, 52g nickel-containing carbon nanotubes, 16g titanium dioxide powder, 50g high-viscosity SB powder, 6g squash powder, 4g citric acid, 7.6g ammonium fluorosilicate, 15g ammonium bicarbonate, 9ml concentration is 66% Nitric acid, add 210ml of water and stir evenly, put it into a kneader and knead for 45 minutes, extrude it into clover strips with a particle size of 1.2mm on the extru...

Embodiment 2

[0041] Preparation of catalyst support:

[0042] The carbon nanotubes loaded with nickel oxide were prepared in the same manner as in Example 1;

[0043] Mix 200g of alumina powder, 52g of nickel-containing carbon nanotubes, 16g of titanium dioxide powder, 50g of high-viscosity SB powder, 6g of scallop powder, 4g of citric acid, 15g of ammonium bicarbonate, 9ml of 66% nitric acid, add 210ml of water and stir well , kneaded in a kneader for 45 minutes, extruded into clover strips with a particle size of 1.2mm on the extruder, air-dried, dried in a vacuum oven at a temperature of 110°C for 4 hours, and dried in a muffle furnace for N 2 The catalyst carrier A2 was obtained by calcining at 550° C. for 4 hours in the atmosphere.

[0044] Preparation of hydrogenation catalyst:

[0045] The preparation method was the same as in Example 1 to obtain hydrogenation catalyst A2-1.

Embodiment 3

[0047] Preparation of catalyst support:

[0048] Same as Example 1, the only difference is that ordinary SB powder is used instead of high-viscosity SB powder to obtain catalyst carrier A3.

[0049] Preparation of hydrogenation catalyst:

[0050] The preparation method was the same as in Example 1 to obtain hydrogenation catalyst A3-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com