Branched sulfonated polyaryletherketone containing benzoxazole ring side group, preparation method and application thereof

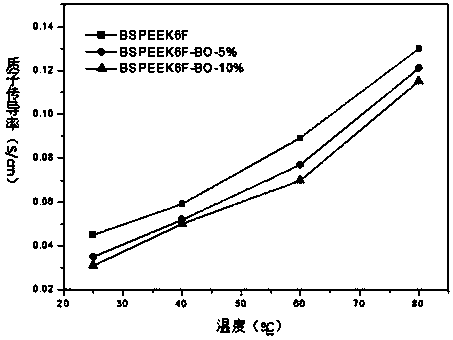

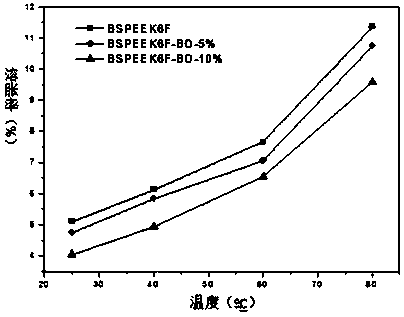

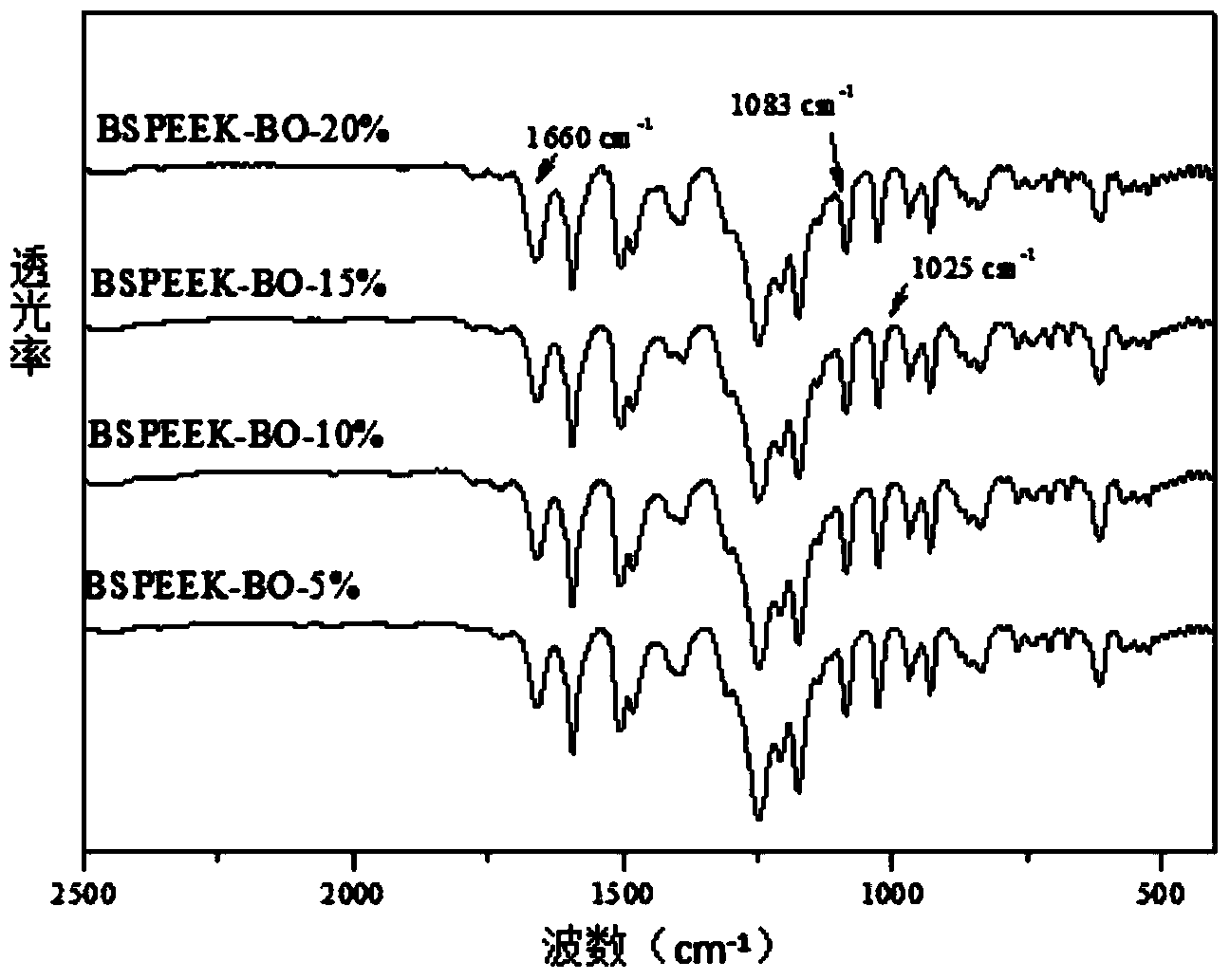

A technology of sulfonated polyaryl ether ketone and benzoxazole ring, applied in the field of polymer chemistry, can solve the problems of reduced antioxidant stability, shortened membrane material life, increased fuel permeability, etc., and achieves good proton conduction rate, good dimensional stability, and high oxidative stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In a three-necked flask equipped with a mechanical stirrer, a water dispenser, a thermometer, a condenser tube, and nitrogen protection, add 0.04mol of tetramethylbiphenol, 0.06mol of diallyl bisphenol A, and 0.05mol of 4 ,4'-difluorobenzophenone, 0.04mol of 3,3'-sodium disulfonate-4,4'-difluorobenzophenone, 0.01mol of 1,3,5-trifluorophenylcarbonylbenzene, with 0.12mol of potassium carbonate is used as a salt-forming agent, dimethylformamide is used as a solvent, toluene is used as a water-carrying agent, and the solid content is 20%. Bring water at 120°C for 3 hours, then distill off the toluene, raise the temperature to 150°C and continue the reaction for 10 hours. After the reaction was complete, the mixture was introduced into distilled water to form a light yellow strip solid, which was pulverized into a fine powder with a pulverizer, washed 5 times with acetone, and then washed 5 times with distilled water. Dry it in an oven at 80°C to obtain a sulfonated polyary...

Embodiment 2

[0028] In a three-neck flask equipped with a mechanical stirrer, a water dispenser, a thermometer, a condenser tube, and nitrogen protection, add 0.08 mol of hexafluorobisphenol A, 0.02 mol of diallyl bisphenol A, and 0.045 mol of 4,4 '-Difluorobenzophenone, 0.05 mol of 3,3'-sodium disulfonate-4,4'-difluorobenzophenone, 0.005 mol of 1,3,5-trifluorophenylcarbonylbenzene, 0.12 mol Potassium carbonate is used as a salt-forming agent, dimethylacetamide is used as a solvent, toluene is used as a water-carrying agent, and the solid content is 20%. Bring water at 130°C for 3 hours, then distill off the toluene, raise the temperature to 160°C and continue the reaction for 8 hours. After the reaction was complete, the mixture was introduced into distilled water to form a light yellow strip solid, which was pulverized into a fine powder with a pulverizer, washed 5 times with acetone, and then washed 5 times with distilled water. Dry it in an oven at 80°C to obtain a sulfonated polyaryl...

Embodiment 3

[0031]In a three-necked flask equipped with a mechanical stirrer, a water dispenser, a thermometer, a condenser tube, and nitrogen protection, add 0.02mol of bisphenol A, 0.08mol of diallyl bisphenol A, and 0.005mol of 4,4'- Difluorobenzophenone, 0.08mol of 3,3'-sodium disulfonate-4,4'-difluorobenzophenone, 0.015mol of 1,3,5-trifluorophenylcarbonylbenzene, 0.12mol of carbonic acid Potassium is used as a salt-forming agent, N-methylpyrrolidone is used as a solvent, toluene is used as a water-carrying agent, and the solid content is 20%. Bring water at 140°C for 3 hours, then distill off the toluene, raise the temperature to 170°C and continue the reaction for 6 hours. After the reaction was complete, the mixture was introduced into distilled water to form a light yellow strip solid, which was pulverized into a fine powder with a pulverizer, washed 5 times with acetone, and then washed 5 times with distilled water. Dry it in an oven at 80°C to obtain a sulfonated polyaryletherk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com