Method for low-pressure demetallization and dechlorination of coal tar

A technology for coal tar and demetallization, applied in refining to remove heteroatoms, etc., can solve problems such as unfavorable deep processing and clean processing, corrosion of equipment, insufficient deep processing capacity, etc. The effect of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

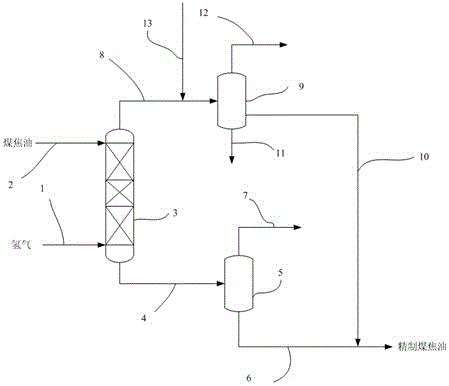

[0026] In order to solve the problem in the prior art that the metal content in the whole fraction of coal tar is very high, which seriously restricts the operation cycle of the main hydrogenation unit, and the chlorine content is also high, so the device will be corroded during the processing, which seriously hinders the hydrogenation process ongoing development issues such as figure 1 As shown, the present invention discloses a method for low-pressure demetallization and dechlorination of coal tar that can be hydrotreated at a lower operating pressure. By introducing hydrogen into the reactor from the bottom of the fixed-bed hydrogenation reactor, the coal tar The raw material is introduced into the reactor from the top of the fixed-bed hydrogenation reactor, and the inside of the reactor is filled with large pore volume protection catalyst, medium pore volume protection catalyst, and small pore volume protection catalyst in order from top to bottom, so that coal tar and hydr...

Embodiment 2

[0054] The difference between this example and Example 1 is that the operating conditions of the fixed-bed hydrogenation reactor are: the average reaction temperature is 250°C, the partial pressure of hydrogen is 3.0MPa, and the space velocity of fresh raw materials is 0.5h -1 , the volume ratio of hydrogen to oil is 350, and it has been verified that the metal content in coal tar is lower than 2.1 μg / g, and the Cl content is lower than 1 μg / g.

Embodiment 3

[0056] The difference between this example and Example 1 is that the operating conditions of the fixed bed hydrogenation reactor are: the average reaction temperature is 375°C, the partial pressure of hydrogen is 8.0MPa, and the space velocity of fresh raw materials is 1.5h -1 , the volume ratio of hydrogen to oil is 900, and it has been verified that the metal content in coal tar is lower than 0.9 μg / g, and the Cl content is lower than 1 μg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com