Hydrogenation pretreatment method of coal tar

A technology for hydrotreating pretreatment and coal tar, applied in hydrotreating process, treating hydrocarbon oil, petroleum industry, etc., can solve the problems of hindering the sustainable development of hydroprocessing, restricting the operation period of the main hydrotreating unit, and high metal content. Suitable for large-scale promotion and application, easy to fully separate, and ensure the effect of long-term operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

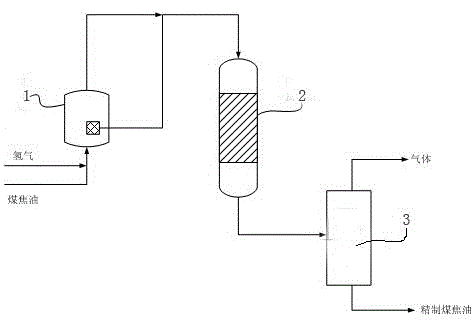

[0027] In order to solve the problem that the high metal content in the full fraction of coal tar existing in the prior art seriously restricts the operation period of the main hydrogenation unit and hinders the sustainable development of hydrogen processing, such as figure 1 As shown, the present invention discloses a coal tar hydrogenation pretreatment method. After mixing coal tar and hydrogen at a relatively low reaction pressure, the mixture is first passed into a slurry bed hydrogenation reactor at high temperature and high space velocity. Then pass it into a fixed-bed hydrogenation reactor at low temperature and low space velocity, and finally produce refined coal tar with a total metal content not higher than 2 μg / g. It has been verified that the present invention is especially suitable for coal tar raw materials with high asphaltene content. processing.

[0028] Concrete implementation method of the present invention is as follows:

[0029] After mixing coal tar and ...

Embodiment 2

[0049] The difference between this example and Example 1 is that the operating conditions of the slurry bed reactor are: the average reaction temperature is 320°C, the hydrogen partial pressure is 3MPa, and the space velocity is 1.0h -1 , the volume ratio of hydrogen to oil is 600; the operating conditions of the fixed bed reactor are: the average reaction temperature is 280°C, the hydrogen partial pressure is 3.0MPa, and the fresh raw material space velocity is 0.5h -1 , the volume ratio of hydrogen to oil is 600, and it has been verified that the metal content in coal tar is lower than 1.5 μg / g.

Embodiment 3

[0051] The difference between this example and Example 1 is that the operating conditions of the slurry bed reactor are: the average reaction temperature is 480°C, the hydrogen partial pressure is 8MPa, and the space velocity is 5.0h -1 , the volume ratio of hydrogen to oil is 800; the operating conditions of the fixed bed reactor are: the average reaction temperature is 380°C, the hydrogen partial pressure is 8.0MPa, and the fresh raw material space velocity is 1.0h -1 , the volume ratio of hydrogen to oil is 800, and it has been verified that the metal content in coal tar is lower than 0.9 μg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com