Method for preparing ultra-thin germanium oxide interface repairing layer on Ge substrate

A technology of germanium oxide and repair layer, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of unfavorable low equivalent oxide thickness, large thickness, etc., and achieve improved interface quality, low cost, and convenient control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

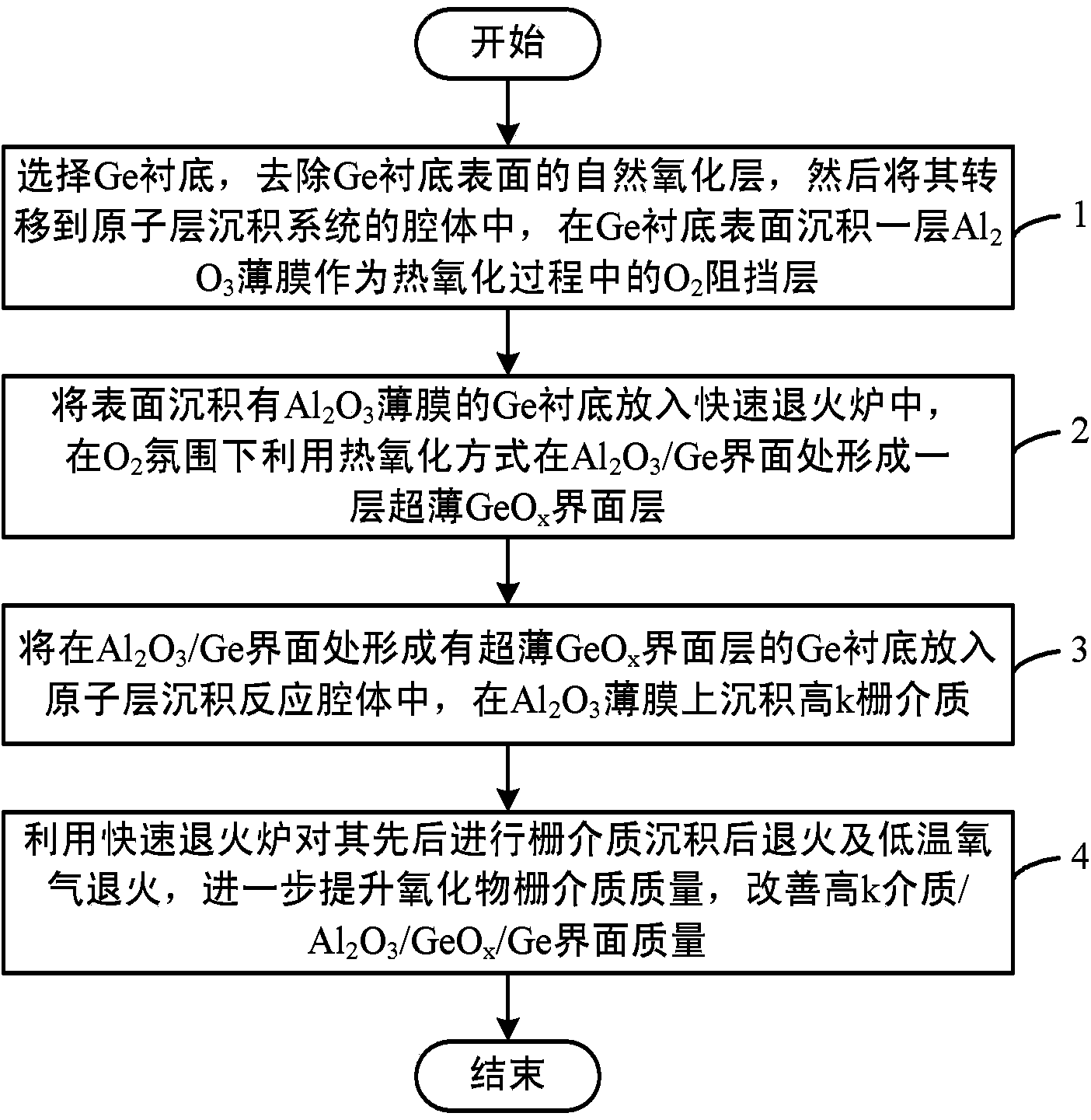

[0024] The invention provides a method for preparing an ultra-thin GeOx interface layer on a Ge substrate, which is used for repairing the high-k gate dielectric / Ge interface, and realizes the interface stability and high quality required by the gate stack in Ge-based MOS devices. This method includes the following steps: first remove the natural oxide layer on the surface of the Ge substrate, and quickly transfer it to the chamber of the atomic layer deposition system to deposit a thin layer of Al 2 o 3 film; then put it into a rapid annealing furnace at O 2 Atmosphere, using thermal oxidation method on Al 2 o 3 / G e A layer of ultrathin GeO x interface layer; then put the sample into the atomic layer deposition rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com