A HEMT gate leakage current separating structure and method based on capacitor structure

A technology of capacitive structure and current separation, applied in the direction of measuring current/voltage, circuit, measuring electricity, etc., can solve difficult problems, achieve reliable results, easy to implement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

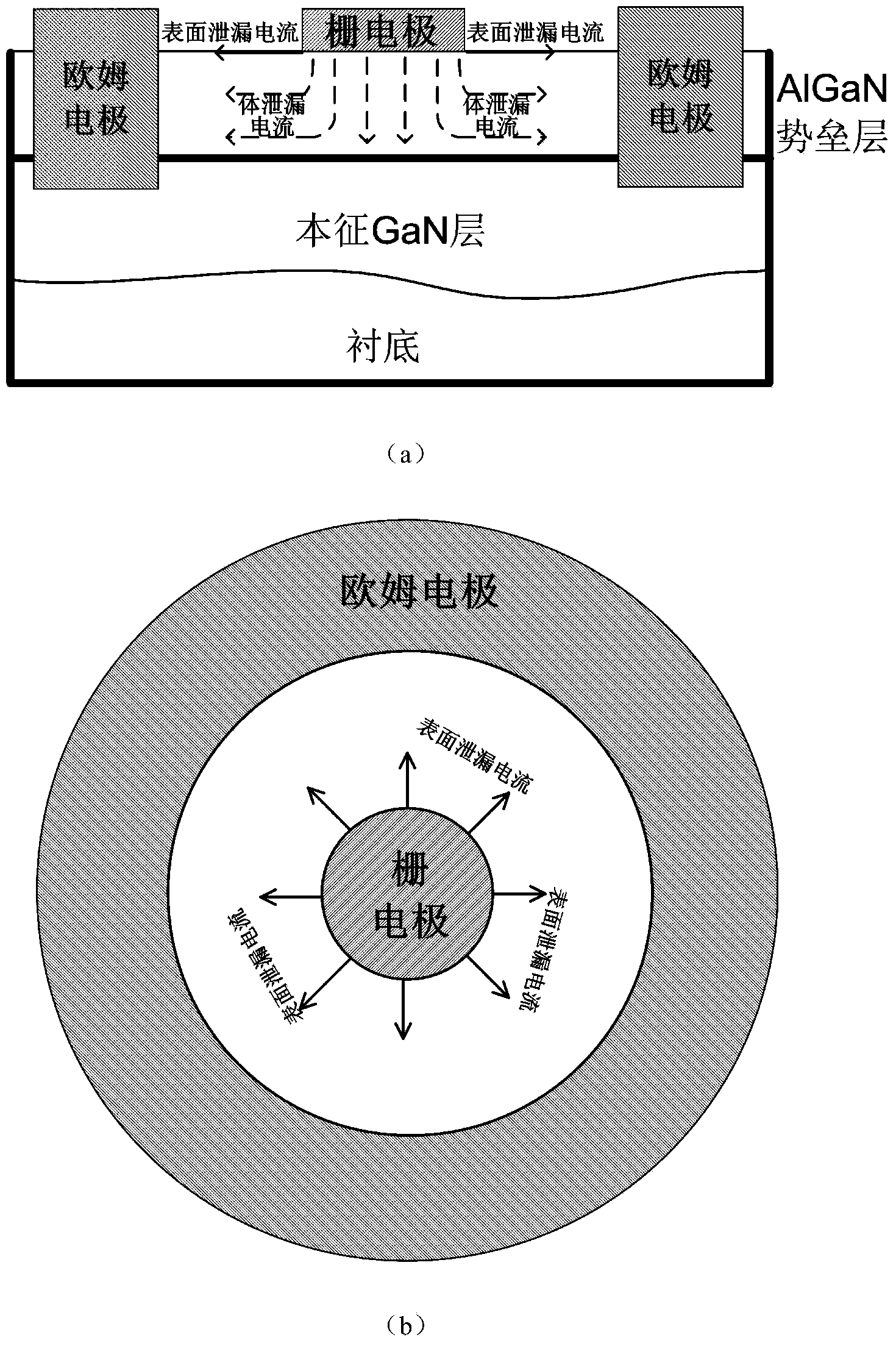

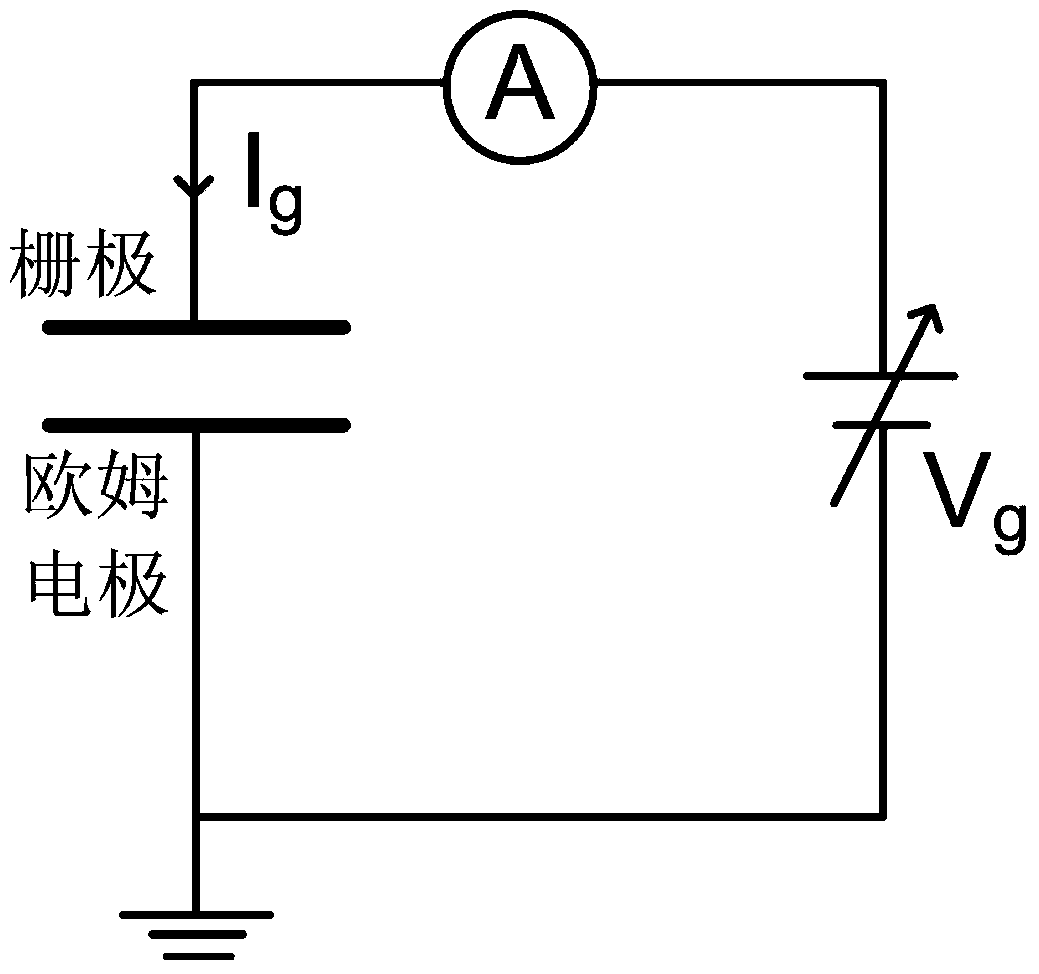

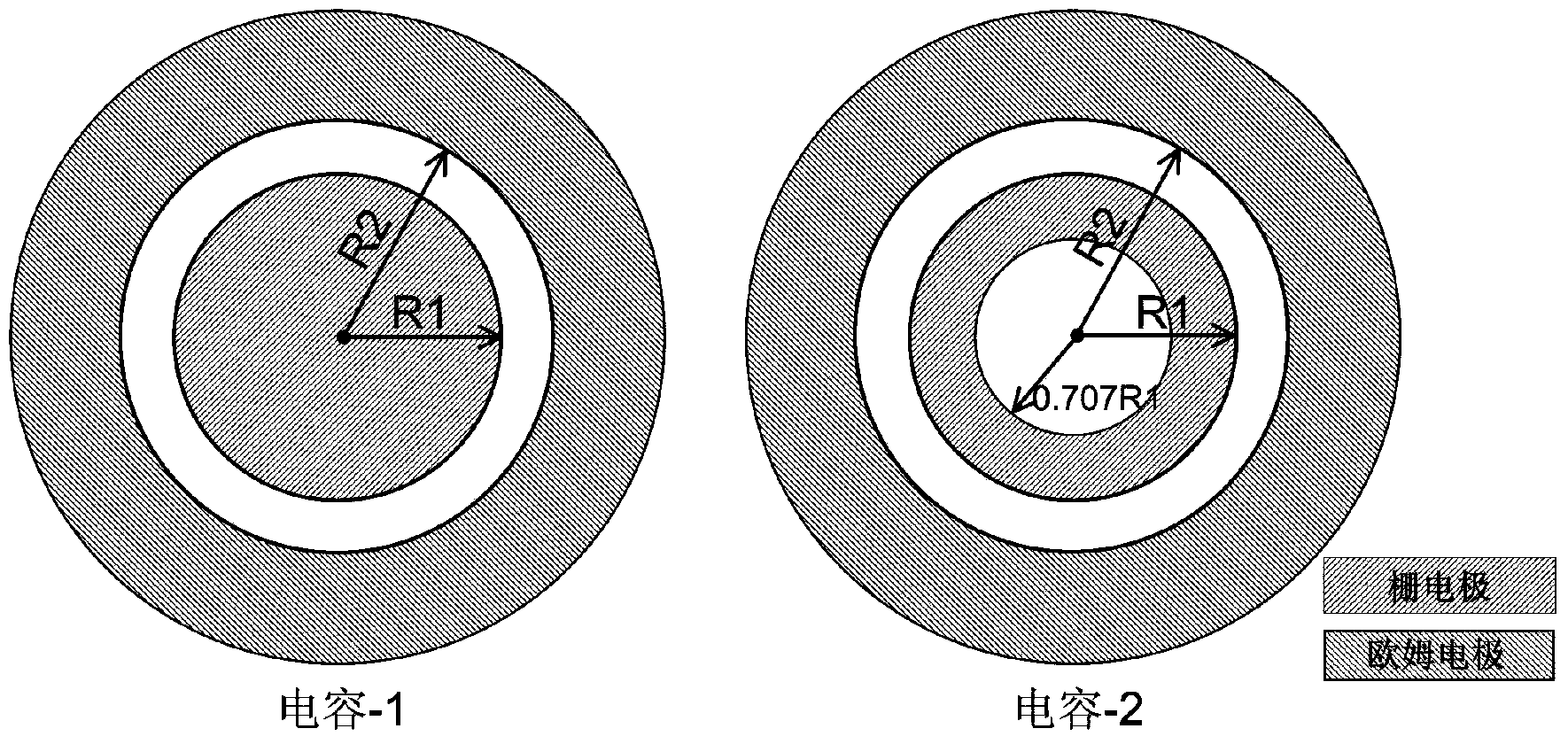

[0029] figure 1 It is a schematic diagram of the gate leakage current components in the ring structure HEMT, (a) cross-sectional view, (b) top view. A typical ring structure HEMT includes two electrodes: a Schottky gate electrode (SchottkyGate) and an ohmic electrode (Ohmic). The gate leakage current of HEMT devices is an important factor affecting device characteristics. As shown in Figure (a), the gate leakage current of HEMT devices mainly includes two parts: the lateral surface leakage current between the Schottky gate and the ohmic contact (I surf ) and the bulk leakage current through the barrier layer perpendicular to the Schottky gate surface (I bulk ); Figure (b) is the top view of the annular HEMT structure, the surface leakage current I surf It is mainly generated by the high electric field between the Schottky gate electrode and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com