Preparation method of p-n type Cu2O/TiO2 nanowire array composite film

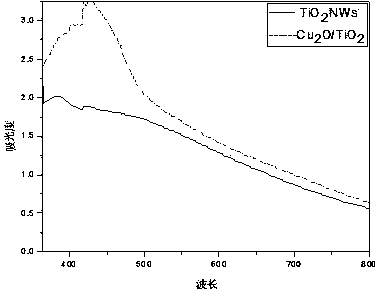

A technology of nanowire array and composite thin film, which is applied in the direction of nanotechnology, nanotechnology, semiconductor/solid-state device manufacturing, etc., can solve the problem of low utilization rate of visible light, achieve high regularity and order, good photoelectric performance, and expand Effect of Response Range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] TiO 2 Fabrication of Nanowire Array Thin Films

[0025] Take 15mL of ultrapure water and 15mL of concentrated HCL with a mass fraction of 38% in a beaker and stir on a magnetic stirrer until they are evenly mixed, then add 0.5mL of tetra-n-butyl titanate dropwise to the above solution, and stir for 30 minutes to form Colorless solution (labeled solution A); put a piece of FTO substrate with the conductive side up in a 50 mL autoclave liner, then transfer the resulting colorless mixed solution A to the autoclave liner and submerge FTO substrate, and finally put the autoclave into an oven at 150°C for 12 hours; after the reaction, cool to room temperature and rinse with deionized water to obtain TiO 2 Nanowire Array Films.

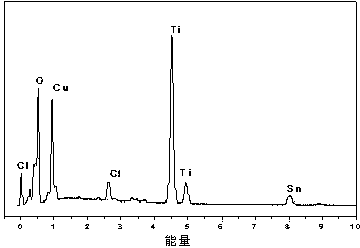

[0026] p-n type Cu 2 O / TiO 2 Preparation of Nanowire Array Composite Thin Film

[0027] Prepare 0.4mol / LCuSO 4 and 3mol / LC 3 h 6 o 3 (Lactic acid) mixed solution, and adjusted to pH = 7 with 5mol / L NaOH solution to obtain a dark blue solution...

Embodiment 2

[0029] TiO 2 Fabrication of Nanowire Array Thin Films

[0030] Take 15mL of ultrapure water and 15mL of concentrated HCL with a mass fraction of 38% in a beaker and stir on a magnetic stirrer until they are evenly mixed, then add 0.5mL of tetra-n-butyl titanate dropwise to the above solution, and stir for 30 minutes to form Colorless solution (labeled solution A); put a piece of FTO substrate with the conductive side up in a 50 mL autoclave liner, then transfer the resulting colorless mixed solution A to the autoclave liner and submerge FTO substrate, and finally put the autoclave into an oven at 150°C for 12 hours; after the reaction, cool to room temperature and rinse with deionized water to obtain TiO 2 Nanowire Array Films.

[0031] p-n type Cu2 O / TiO 2 Preparation of Nanowire Array Composite Thin Film

[0032] Prepare 0.4mol / LCuSO 4 and 3mol / LC 3 h 6 o 3 (Lactic acid) mixed solution, and adjusted to pH = 8 with 5mol / L NaOH solution to obtain a dark blue solution (...

Embodiment 3

[0034] Fabrication of Nanowire Array Thin Films

[0035] Take 15mL of ultrapure water and 15mL of concentrated HCL with a mass fraction of 38% in a beaker and stir on a magnetic stirrer until they are evenly mixed, then add 0.5mL of tetra-n-butyl titanate dropwise to the above solution, and stir for 30 minutes to form Colorless solution (labeled solution A); put a piece of FTO substrate with the conductive side up in a 50 mL autoclave liner, then transfer the resulting colorless mixed solution A to the autoclave liner and submerge FTO substrate, and finally put the autoclave into an oven at 150°C for 12 hours; after the reaction, cool to room temperature and rinse with deionized water to obtain TiO 2 Nanowire Array Films.

[0036] p-n type Cu 2 O / TiO 2 Preparation of Nanowire Array Composite Thin Film

[0037] Prepare 0.4mol / LCuSO 4 and 3mol / LC 3 h 6 o 3 (Lactic acid) mixed solution, and adjusted to pH = 9 with 5mol / L NaOH solution to obtain a dark blue solution (m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com