Adsorption and degradation of sulfated graphene-TiO2 composite material to amide and organophosphorus pesticides

A technology of sulfonated graphene and composite materials, which is applied in the field of photocatalytic technology and pesticide degradation, can solve the problems of unreported application of pesticide photocatalytic degradation and hydrothermal synthesis of pesticide degradation, etc., and achieves convenient operation, low cost, The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Sulfonated graphene was synthesized according to literature reports (Chem. Mater., 1998, 10, 718-722).

[0023] Using sulfonated graphene as raw material, sulfonated graphene-TiO was prepared according to reference 2 Composite materials (Int. J. Hydrogen Energ, 2008, 37, 811-815). Wherein the quality of sulfonated graphene is 13.369g, titanium tetrachloride is 6.127mL.

[0024] The prepared sulfonated graphene-TiO 2 After the composite material was washed with deionized water to neutrality, it was diluted to a suspension with a concentration of 3000mg / L, and was mixed evenly by ultrasonication.

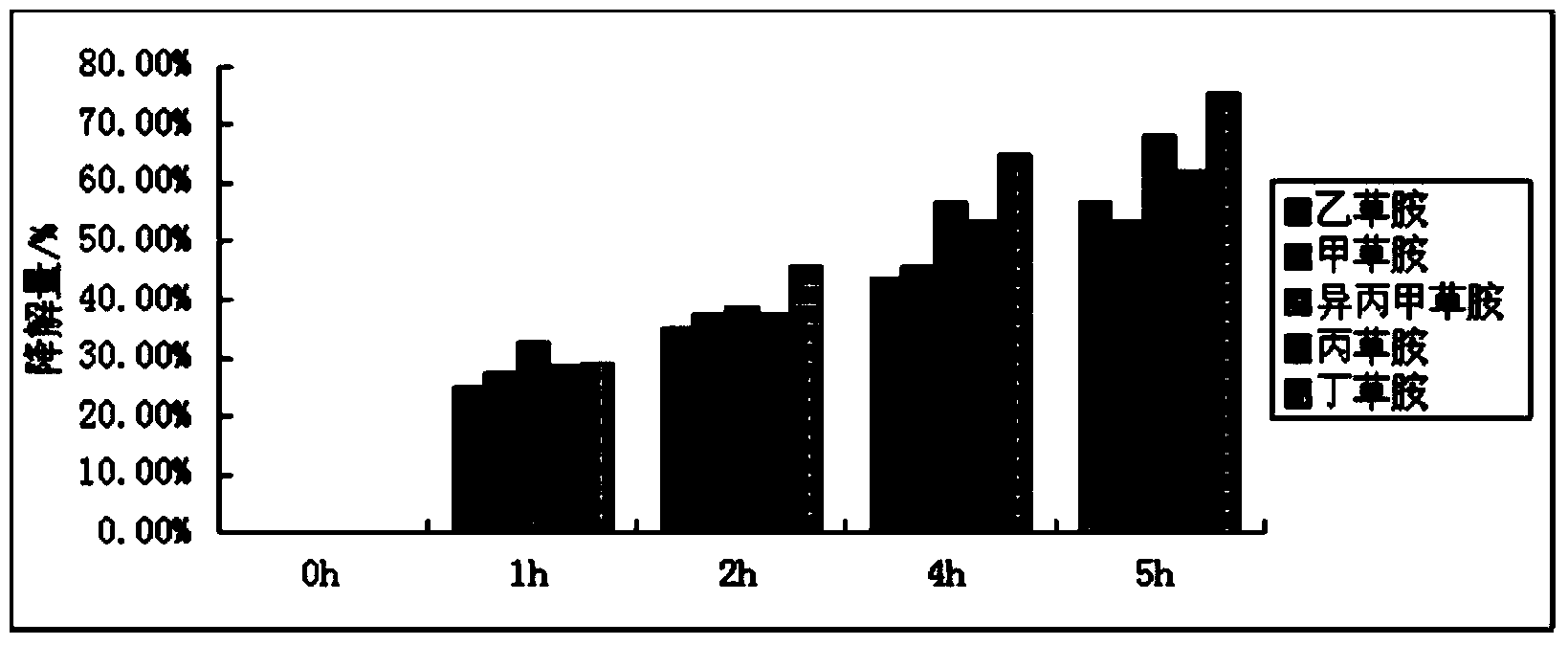

[0025] Add 9mL of the prepared suspension to the water sample added with amide herbicides, vortex for 2min, centrifuge for 5min, discard the water layer, then add 4mL Wahaha water, vortex for 30s to mix evenly. Take 2mL of the suspension and place it under simulated sunlight for 1h, 2h, 4h and 5h respectively, and set up a control experiment.

[0026] Add 4 mL of ethyl acet...

Embodiment 2

[0029] Sulfonated graphene was synthesized according to literature reports (Chem. Mater., 1998, 10, 718-722).

[0030] Using sulfonated graphene as raw material, sulfonated graphene-TiO was prepared according to reference 2 Composite materials (Int. J. Hydrogen Energ, 2008, 37, 811-815). Wherein the quality of sulfonated graphene is 13.369g, titanium tetrachloride is 6.127mL.

[0031] The prepared sulfonated graphene-TiO 2 After the composite material was washed with deionized water to neutrality, it was diluted to a suspension with a concentration of 3000mg / L, and was mixed evenly by ultrasonication.

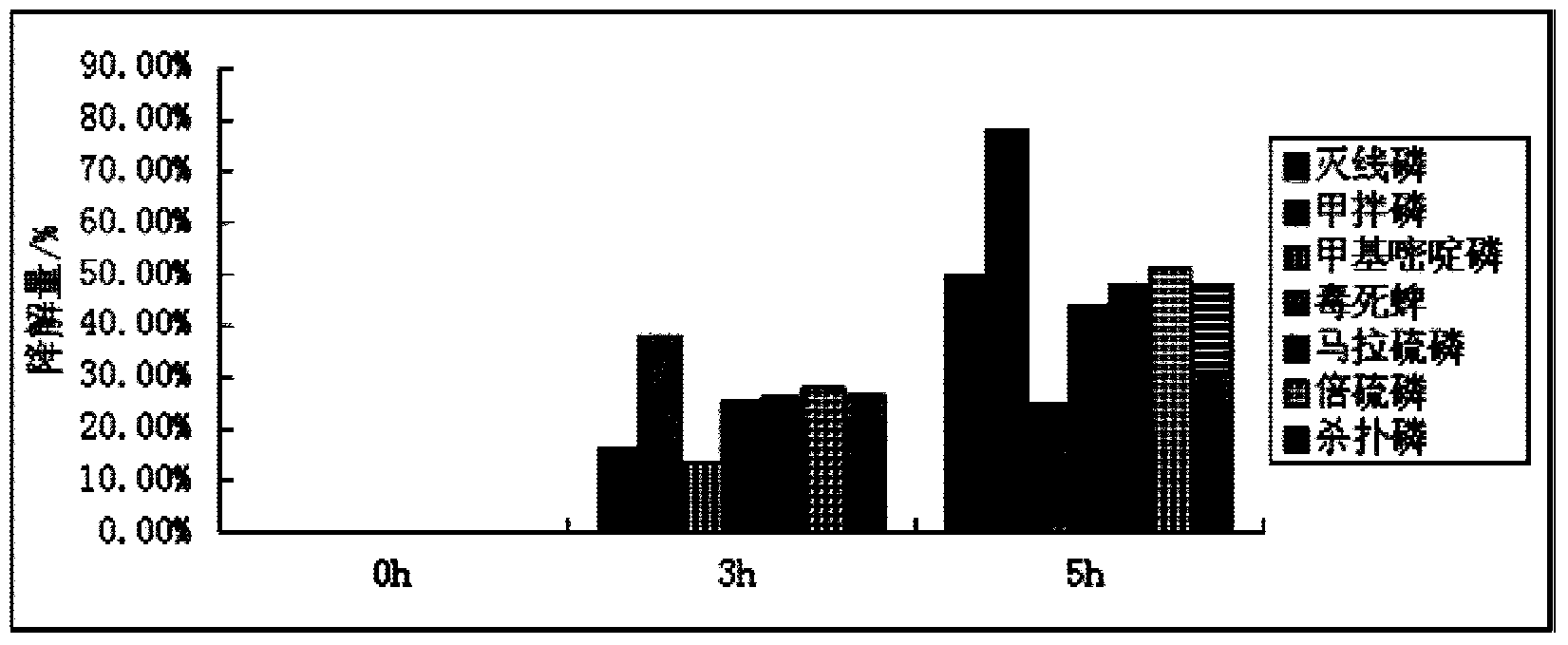

[0032] Add 9mL of the prepared suspension to the water sample added with organophosphorus insecticides, vortex for 2min, centrifuge for 5min, discard the water layer, then add 4mL Wahaha water, vortex for 30s to mix evenly. Take 2mL of the suspension and place it under simulated sunlight for 1h, 2h, 4h and 5h respectively, and set up a control experiment.

[0033] Add 4 mL ...

Embodiment 3

[0036] Graphene-TiO2 composites were prepared according to the method reported in the literature (Int.J.HydrogenEnerg, 2008, 37, 811-815). Among them, the mass of graphene oxide is 13.369g, and that of titanium tetrachloride is 6.127mL.

[0037] The prepared graphene-TiO 2 After the composite material was washed with deionized water to neutrality, it was diluted to a suspension with a concentration of 3000mg / L, and was mixed evenly by ultrasonication.

[0038] Add 9 mL of the prepared suspension to the water sample added with amide herbicides, vortex for 2 min, centrifuge for 5 min, discard the water layer, then add 10 mL of ethyl acetate and 3 g of sodium chloride, vortex for 2 min, centrifuge, and take After removing water, 1mL of the supernatant was passed through a 0.22μm organic phase filter membrane, and then detected by GC-MS.

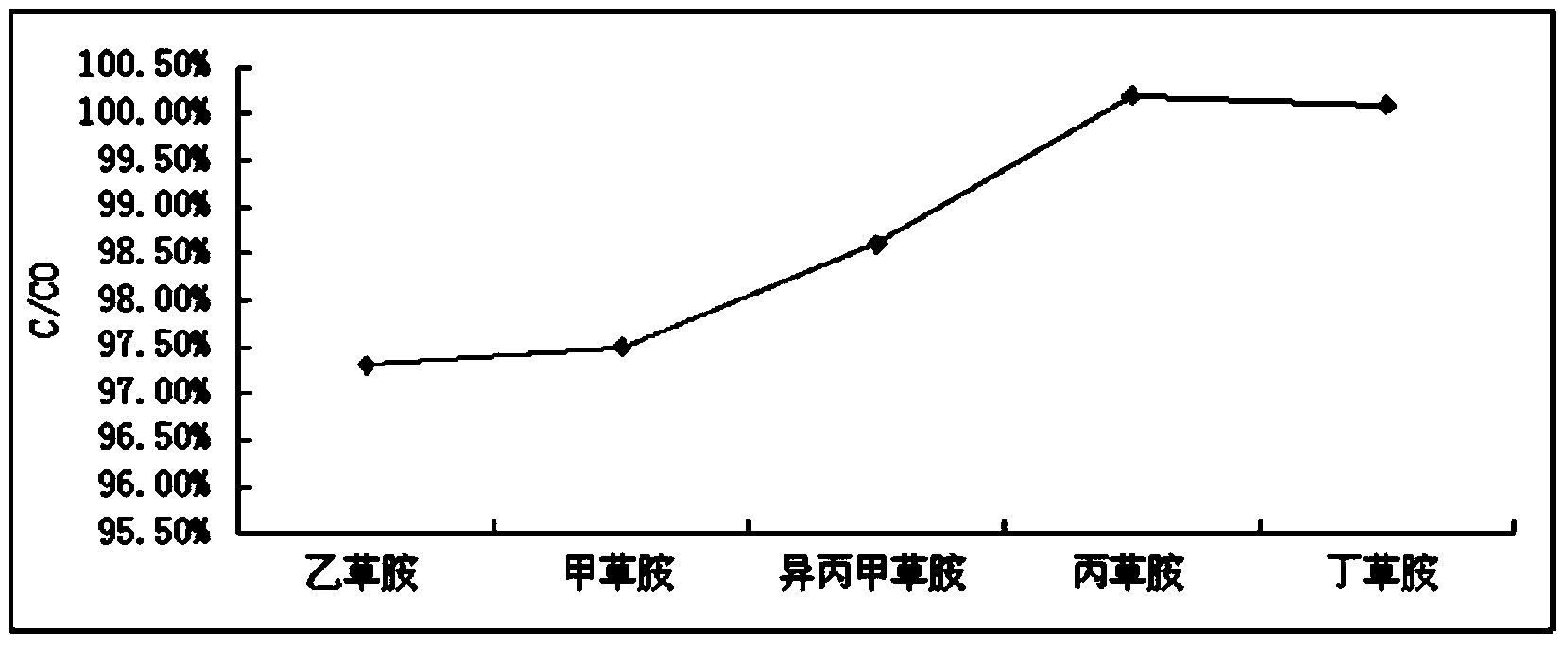

[0039] The results show that graphene-TiO 2 The composite material has good adsorption effects on five amide herbicides (including alachlor, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com