Micro/nano array and application thereof in micro/nano material standard bending strain loading

A technology of nano-materials and bending strain, applied in metal material coating technology, micro-structure technology, micro-structure devices, etc., to achieve the effect of simple and clear strain state, simple operation mode and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1, preparation micro / nano support array

[0045] 1) Spin-coat SU-8 photoresist on the substrate at a speed of 500rpm for 10 seconds, then spin-coat at a speed of 3000rpm for 60 seconds, then keep at 65°C for 1 minute and then increase the temperature at 2°C / s The temperature was raised to 95° C. for 3 minutes for pre-baking to obtain a photoresist layer with a thickness of 15 μm.

[0046] 2) Use a photolithographic mask with a pre-designed pattern to mask, and use ultraviolet light to expose the photoresist layer (such as SU-8 photoresist) obtained in step 1) at an exposure dose of 13mW / cm 2 1. Expose under the condition that the exposure time is 12s, and then develop with SU-8 photoresist special developer (PGMEA—MicroChem, USA) for 4 minutes, remove the unexposed SU-8 photoresist, and get Micro / nano support arrays.

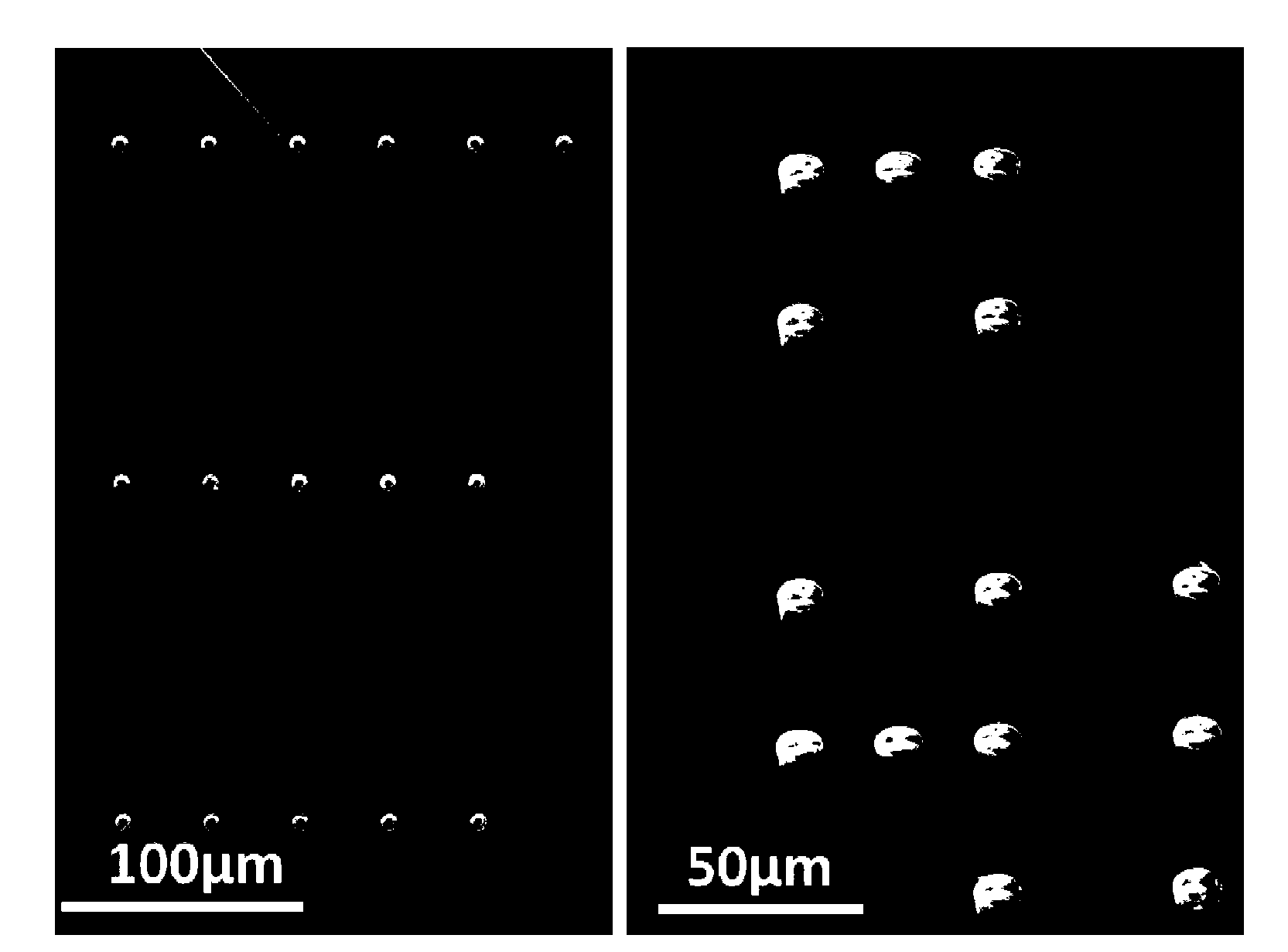

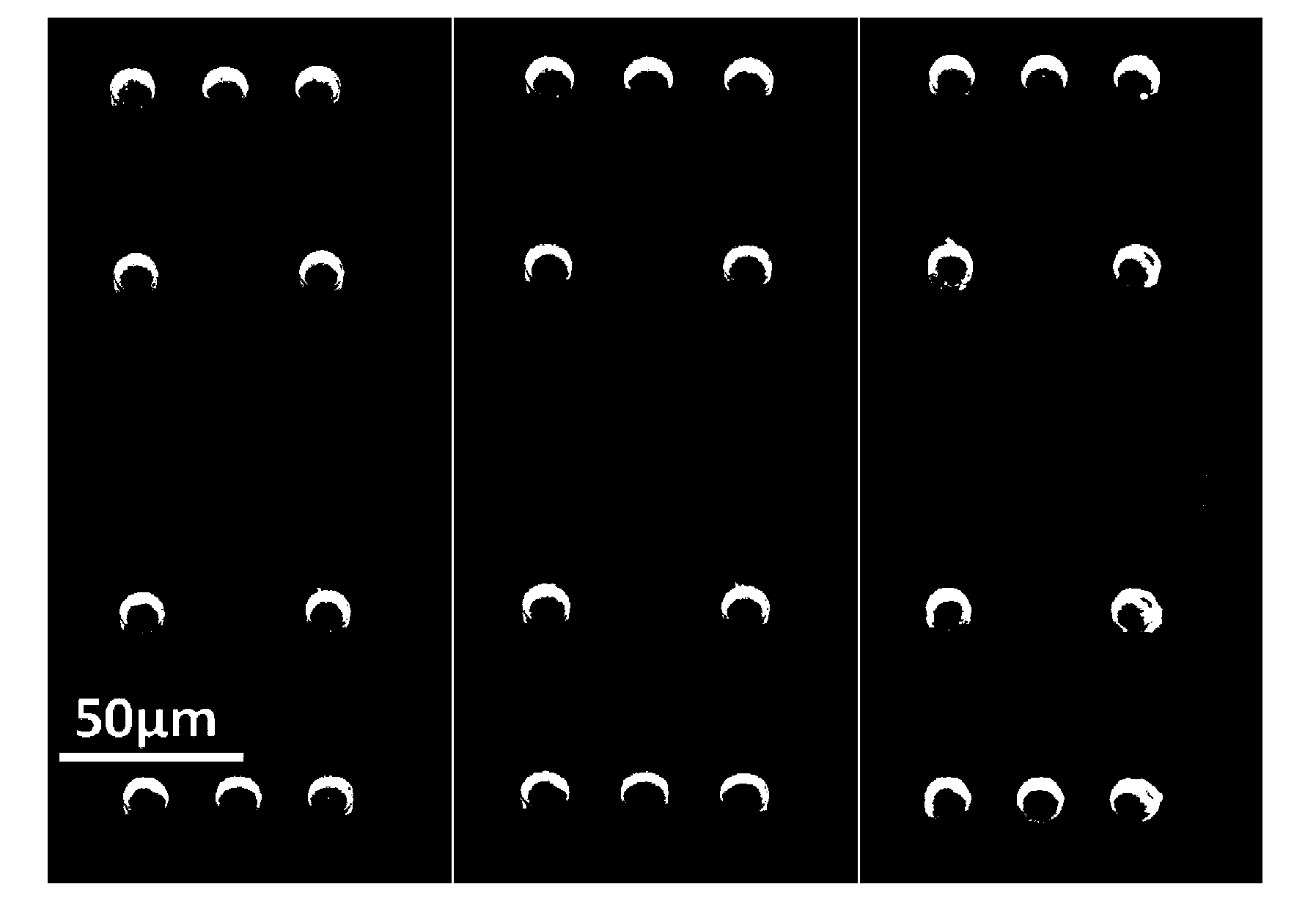

[0047] The micro / nano support array obtained in this embodiment is composed of a substrate and several columnar structures arranged at inter...

Embodiment 2

[0048] Example 2, standard bending strain loading of micro / nano materials

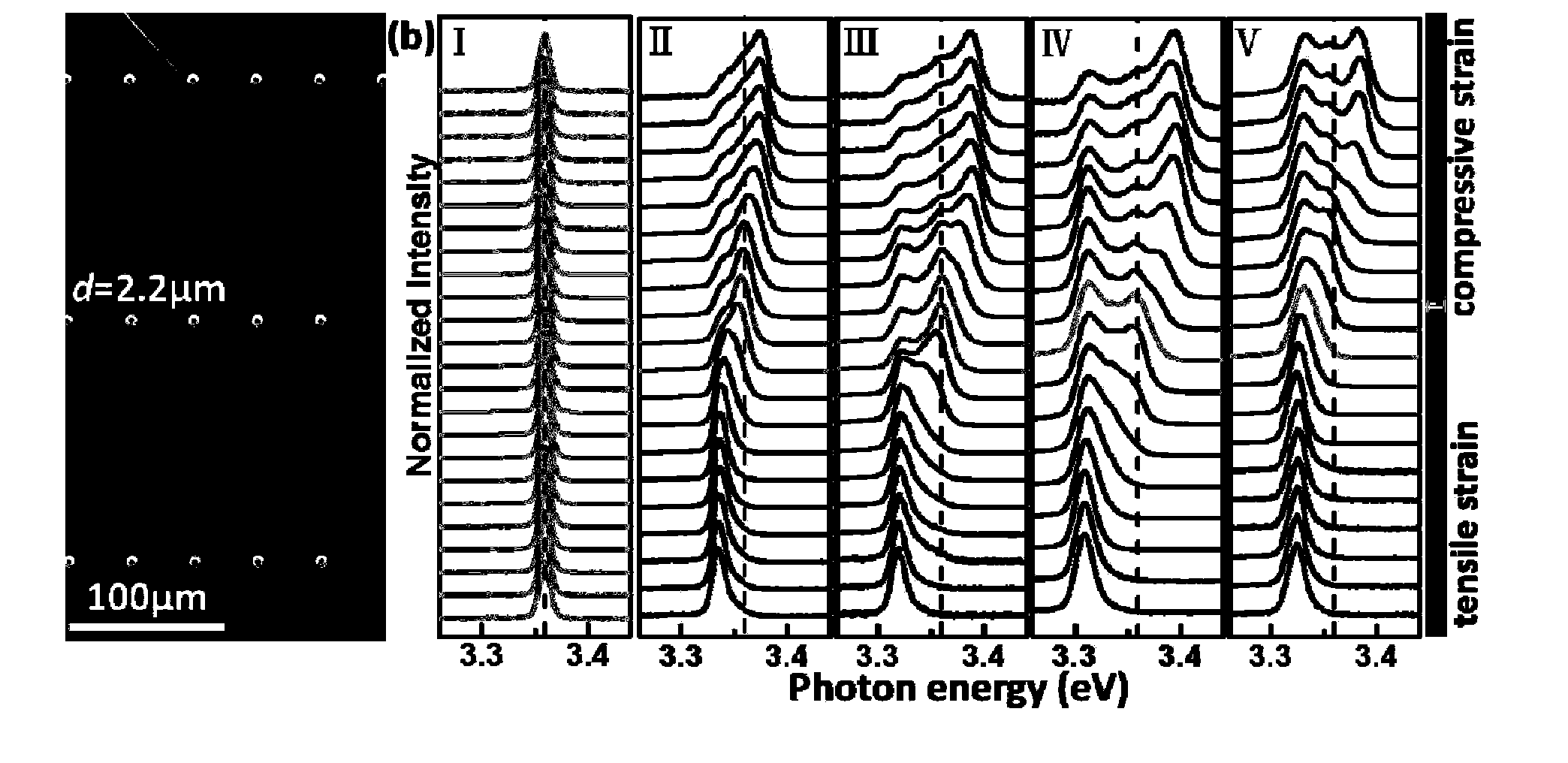

[0049] Using the micro-operating system under the optical microscope, transfer the quasi-one-dimensional target micro / nano material ZnO micro / nano wire to the micro / nano support array prepared in Example 1, so that a single ZnO micro / nano wire (with a diameter of 0.2~ 5.0μm, length 300~800μm) suspended between three or four columnar structures to complete the standard bending strain loading of a single ZnO micro / nanowire;

[0050] The micromanipulation system used consists of a telephoto optical microscope (BX51M, OLYMPUS) and two glass tips controlled by a three-axis hydraulic system (MMO-202ND, OLYMPUS). The ZnO micro / nano wires can be conveniently transferred from the growth substrate to the substrate prepared with micro / nano arrays by real-time observation under a microscope.

[0051] Perform low-temperature CL spectrum characterization on the cross-section of the standard curved sample to check t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com