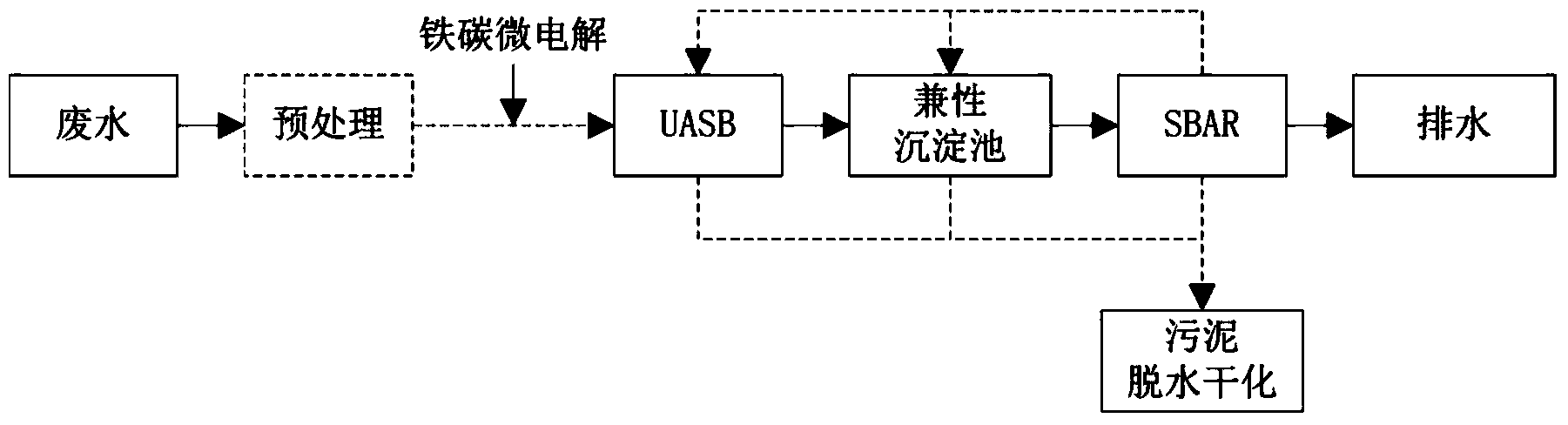

Anaerobic-aerobic stabilization process for high concentration organic wastewater

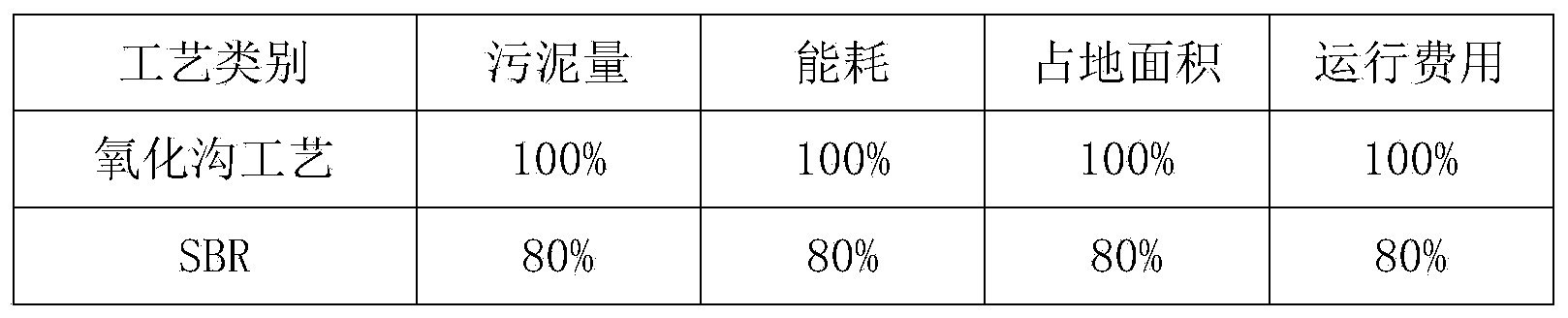

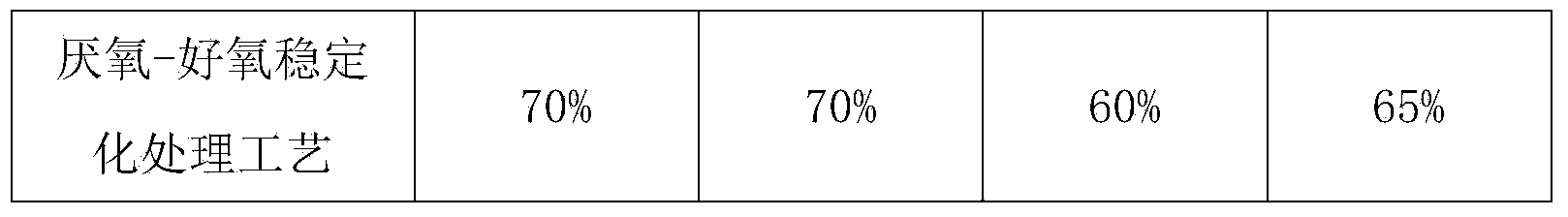

A stabilized treatment and organic wastewater technology, applied in the direction of aerobic and anaerobic process treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of low volume load, large aeration, energy high volumetric load, shortened process, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The wastewater flow rate of a petrochemical enterprise is 10000m 3 / d, COD concentration 1000-1500mg / L, ammonia nitrogen concentration 90-140mg / L, sulfide concentration 40-12mg / L, petroleum concentration 600-50mg / L. The process of the invention mainly makes the petrochemical waste water pass through the anaerobic-aerobic reactor and then settle and discharge directly.

[0031] 1. The sewage first passes through the pretreatment degreaser to remove most of the heavy oil, slick oil and remaining emulsified oil;

[0032] 2. The sewage treated by the pretreatment degreaser is treated by the iron-carbon micro-electrolysis process and then enters the UASB anaerobic reactor; Anaerobic Granular Sludge

[0033] 3. Sewage enters the UASB anaerobic reactor for anaerobic digestion, quickly starts the UASB reactor, the reaction temperature is 35-38°C, the rising flow rate is 0.6-0.8m / h, the reflux ratio is 100%-200%, and the volume load is 8- 12kgCOD / (m 3 d);

[0034] 4. The ef...

Embodiment 2

[0038] A food company has a waste water volume of 15000m 3 / h, COD concentration 300-1000mg / L, SS concentration 200-400mg / L, BOD concentration 200-600mg / L, petroleum 600-50mg / L, first filter for degreasing treatment;

[0039] 2. After the sewage is treated by the iron-carbon micro-electrolysis process, it enters the UASB anaerobic reactor;

[0040] 3. The sewage enters the UASB anaerobic reactor for anaerobic digestion, the reaction temperature is 35-38°C, the upflow velocity is 0.8-1.2m / h, the reflux ratio is 150%-200%, and the volume load is 10kgCOD / (m 3 d);

[0041]4. The effluent from the UASB anaerobic reactor passes through the intermediate sedimentation tank for primary sedimentation, and part of it flows back to the UASB as an internal circulation, and the effluent from the sedimentation tank enters the SBAR aerobic reactor;

[0042] 5. The SBAR aerobic reactor has a cycle of 3 hours, a drainage ratio of 60-80%, and settling for 20 minutes. The volume of aerobic gran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com