Treating method for landfill leachate

A landfill leachate and leachate technology, which is applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems of not meeting the requirements of the secondary standard, large floor space, and high operating costs , to achieve the effects of strong ability to adapt to water quality changes, high impact load resistance, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

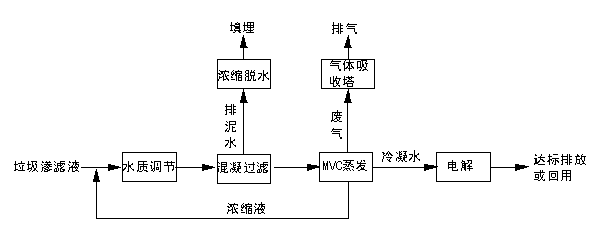

[0016] Embodiment 1: as figure 1 Shown, a kind of method for processing landfill leachate, its technological process comprises the following steps:

[0017] (1) Water quality regulation

[0018] The landfill leachate is passed into the adjustment tank, and an impeller stirring device is installed in the adjustment pool, and the landfill leachate is mixed evenly through stirring, so that the water quality and quantity of the landfill leachate can be adjusted, and the impact load resistance of the subsequent treatment process can be improved. The water quality and water quantity entering the follow-up treatment unit are basically stable through the regulating pool, and the impact of water quality and water quantity on the follow-up treatment unit is reduced.

[0019] (2) coagulation filtration

[0020] Transfer the uniformly mixed leachate in step (1) to the microfiltration membrane tank, add PAC (polyaluminum chloride) and PAM (polyacrylamide) to the leachate for coagulat...

Embodiment 2

[0026] Example 2: It is basically the same as Example 1, except that in step (2), the dosage of coagulant PAC is 500 mg / L, and the dosage of PAM is 15 mg / L.

[0027] The volume of the treated dope in step (3) is about 10% of the volume of landfill leachate.

[0028] During electrolysis in step (4), the current density is 40mA / cm 2 , Voltage 6V.

[0029] The result after adopting the present invention: after the landfill leachate is treated, the removal rate of COD can reach 95.7%, the removal rate of BOD can reach 95.9%, and the removal rate of ammonia nitrogen can reach 95.2%.

Embodiment 3

[0030] Example 3: It is basically the same as Example 1, except that in step (2), the dosage of coagulant PAC is 800 mg / L, and the dosage of PAM is 20 mg / L.

[0031] The volume of the treated dope in step (3) is about 5% of the volume of landfill leachate.

[0032] During electrolysis in step (4), the current density is 60mA / cm 2 , Voltage 10V.

[0033] The result after adopting the present invention: after the landfill leachate is treated, the removal rate of COD can reach 96.4%, the removal rate of BOD can reach 96.8%, and the removal rate of ammonia nitrogen can reach 95.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com