Rubber powder material, rubber powder polyphenyl granule, heat-insulating material and preparation methods thereof

A technology for rubber powder polystyrene particles and polystyrene particles, which is used in rubber powder materials, thermal insulation materials and their preparation, and rubber powder polystyrene particles, can solve the problems of high thermal conductivity, poor fire safety, high water absorption, etc. problems, to achieve the effect of high combustion performance, high fire safety, and reduced water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

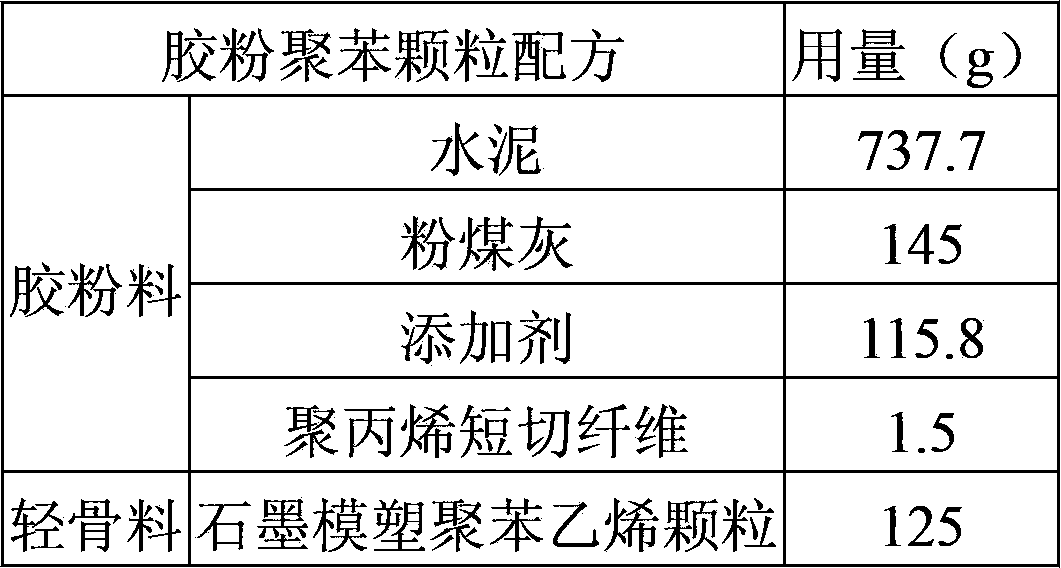

[0052] See Table 1 and Table 2 for the formula and additives of rubber powder polyphenylene particles in Example 1.

[0053] The formula of rubber powder polyphenylene particle of table 1 embodiment 1

[0054]

[0055] The additive formula of table 2 embodiment 1

[0056] Additive formula

Content (wt%)

Hydroxypropyl Methyl Cellulose Ether

3

Inorganic thickening water retention powder (montmorillonite)

40.35

Active silica fume

4

wood fiber

40

EVA latex powder

11

0.25

Hydrophobic agent

1.4

[0057] The preparation method of rubber powder material, it may further comprise the steps:

[0058] (1) Mix cement and chopped fibers for 2-3 minutes under stirring until the mixture is evenly mixed to obtain mixture A;

[0059] (2) Mix mixture A with fly ash and additives for 3 to 5 minutes until the mixture is evenly mixed to obtain rubber powder.

[0060] The ...

Embodiment 2

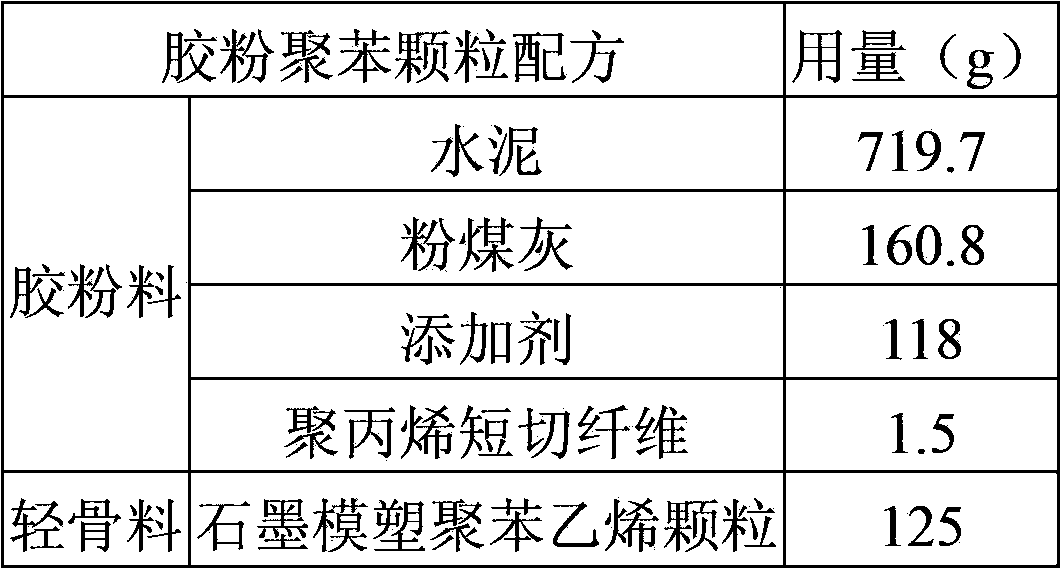

[0064] See Table 3 and Table 4 for the formula and additives of rubber powder polyphenylene particles in Example 2.

[0065] The formula of rubber powder polyphenylene particle of table 3 embodiment 2

[0066]

[0067] The additive formula of table 4 embodiment 2

[0068] Additive formula

Content (wt%)

Hydroxypropyl Methyl Cellulose Ether

4

Inorganic thickening water retention powder (montmorillonite)

40.5

Active silica fume

3.6

wood fiber

40.1

EVA latex powder

10

Starch ether

0.3

Hydrophobic agent

1.5

[0069] The preparation method of the rubber powder material and the rubber powder polyphenylene particles in Example 2 is the same as in Example 1.

[0070] The preparation method of rubber powder polystyrene particle insulation material, it comprises the following steps:

[0071] Mix and stir the rubber powder polyphenylene particles of Example 2 with water unti...

Embodiment 3

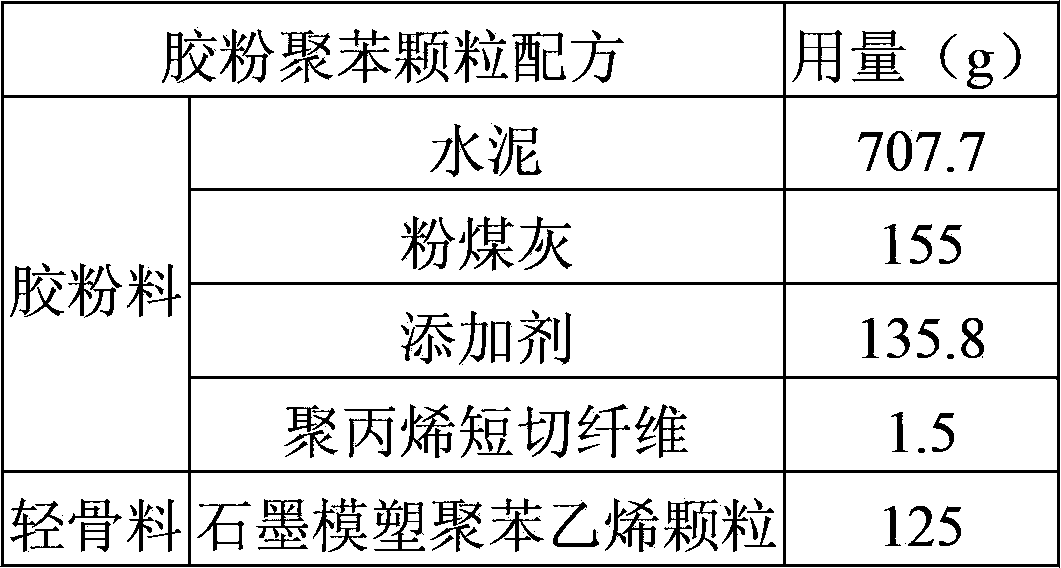

[0073] The formula and additives of rubber powder polyphenylene particles in Example 3 are shown in Table 5 and Table 6.

[0074] The formula of rubber powder polyphenylene particle of table 5 embodiment 3

[0075]

[0076] The additive formula of table 6 embodiment 3

[0077] Additive formula

Content (wt%)

Hydroxypropyl Methyl Cellulose Ether

2.5

Inorganic thickening water retention powder (montmorillonite)

40

Active silica fume

4.5

wood fiber

40

EVA latex powder

11.5

[0078] Starch ether

0.2

Hydrophobic agent

1.3

[0079] The preparation method of the rubber powder material and the rubber powder polyphenylene particles in Example 3 is the same as in Example 1.

[0080] The preparation method of rubber powder polystyrene particle insulation material, it comprises the following steps:

[0081] Mix and stir the rubber powder polyphenylene particles of E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com