Preparation method of maleic anhydride grafted vegetable oil acid

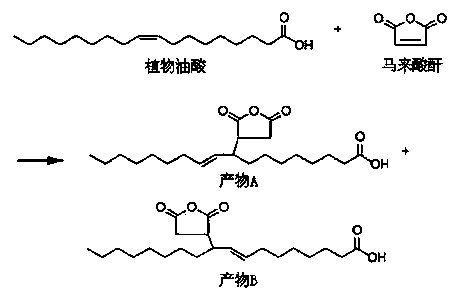

A technology of vegetable oleic acid and maleic anhydride, applied in the field of materials, can solve the problems of industrial production limitation, high product cost and high reaction temperature, and achieve the effects of low cost, safe raw material and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In a 1L reactor with a stirrer, a thermometer and a condensing reflux device, add 1mol vegetable oleic acid, 2mol maleic anhydride, 0.01mol dibutyltin dilaurate, 10g toluene, and pass through N 2 protection, under stirring conditions, the temperature was raised to 180°C, and the reaction was kept for 10 hours. After the reaction was completed, the unreacted maleic anhydride, vegetable oleic acid and solvent were evaporated under reduced pressure, the reaction yield was 75wt%, and the product was light yellow viscous liquid.

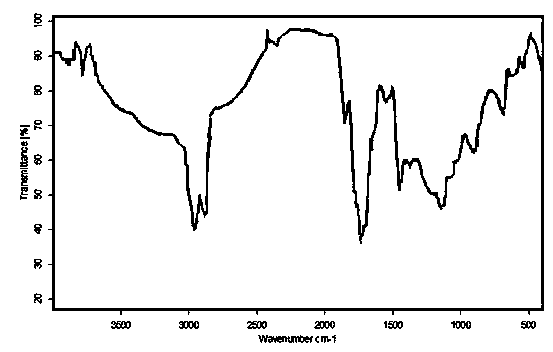

[0025] figure 1 Be the infrared spectrogram of product of the present invention, show in spectrogram: 1860 cm -1 、1781 cm -1 、1161cm -1 It is the characteristic absorption peak of maleic anhydride. From this it can be seen that maleic anhydride has been grafted onto vegetable oleic acid, and the product of the present invention has formed.

Embodiment 2

[0027] In a 1L reaction kettle with a stirrer, a thermometer and a condensing reflux device, add 1mol vegetable oleic acid, 1mol maleic anhydride, 0.005mol dibutyltin dilaurate, 10g toluene, and pass through N 2 protection, under stirring conditions, the temperature was raised to 150°C, and the reaction was kept for 5 hours. After the reaction was completed, the unreacted maleic anhydride, vegetable oleic acid and solvent were evaporated under reduced pressure. The reaction yield was 48wt%, and the product was light yellow viscous liquid.

Embodiment 3

[0029] In a 1L reaction kettle with a stirrer, a thermometer and a condensing reflux device, add 1mol vegetable oleic acid, 3mol maleic anhydride, 0.02mol dibutyltin dilaurate, 10g toluene, and pass through N 2 Protection, under the condition of stirring, the temperature was raised to 170°C, and the reaction was kept for 6 hours. After the reaction was completed, the unreacted maleic anhydride, vegetable oleic acid and solvent were evaporated under reduced pressure, the reaction yield was 68wt%, and the product was light yellow viscous liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com