Preparation method of five-membered bicyclic guanidine compounds

A compound and bicyclic guanidine technology, which is applied in the field of preparation of five-membered bicyclic guanidine compounds, can solve the problems of chirality, long reaction time, danger, etc., and achieve the effects of simple process operation and favorable production scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

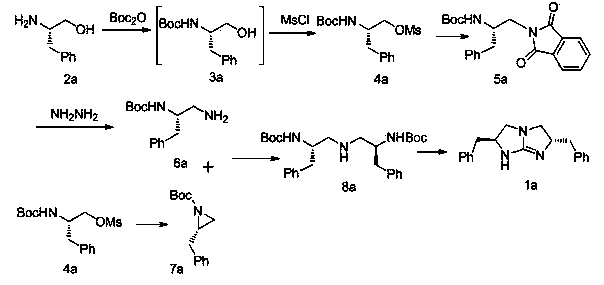

[0039] Preparation of S, S-dibenzyl five-membered bicyclic guanidine 1a

[0040]

[0041] Step 1: Preparation of Compound 4a

[0042] Add 2a (60g, 0.40mol) and ethyl acetate (480mL) into a 1000mL three-neck flask, stir at room temperature for 5min, and add Boc2O (96g, 0.44mol) dropwise. After the dropwise addition, react at room temperature for 1 h, and then add TEA (52.6 g, 0.52 mol) dropwise. After the dropwise addition was completed, MsCl (50.5 g, 0.44 mol) was slowly added dropwise. After the dropwise addition was completed, react at room temperature for 15 minutes, add 300ml of water to quench the reaction, concentrate under reduced pressure to remove ethyl acetate, filter, wash the filter cake with water (50mlx3), and dry in vacuo to obtain 124.2g of white solid 4a with a yield of 95%. 1HNMR (400 MHz, CDCl 3 ): δ 1.40 (s,9H), 2.69-2.95 (m,2H), 3.01 (s,3H ),4.05-4.13 ( m,2H), 4.20-4.29 (m ,1H), 4.73(brs,1H ) , 7.18-7.38 (m ,5H).

[0043]

[0044] Step 2: Preparat...

Embodiment 2

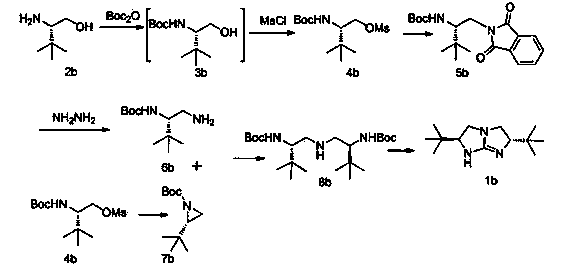

[0059] Preparation of S, S-bis-tert-butyl five-membered bicyclic guanidine 1b

[0060]

[0061] Step 1: Preparation of Compound 4b

[0062] Add 2b (46.9g, 0.40mol) and ethyl acetate (470mL) into a 1000mL three-necked flask, stir at room temperature for 5min, and add Boc2O (96g, 0.44mol) dropwise. After the dropwise addition, react at room temperature for 1 h, and then add TEA (52.6 g, 0.52 mol) dropwise. After the dropwise addition was completed, MsCl (50.5 g, 0.44 mol) was slowly added dropwise. After the dropwise addition was completed, react at room temperature for 15 minutes, add 300ml of water to quench the reaction, separate the organic layer, and extract the aqueous layer with ethyl acetate (80mLx2). The combined organic layers were dried over anhydrous sodium sulfate and concentrated under reduced pressure to obtain 111.1 g of white solid 4b, with a yield of 94%. 1HNMR (300 MHz, CDCl 3 ) : δ 0.98 (s, 9H), 1.45 (s, 9H), 3.04 (s, 3H), 3.73 (m, 1H), 4.30 (dd, 2H), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com