Preparation method of sodium ascorbyl phosphate

A technology of sodium phosphate and vitamins, applied in the field of preparation of vitamin C derivatives, can solve the problems of difficult product separation and purification, complex synthesis process, and low total product yield, and achieve high impurity removal efficiency, simple process, and shortened reaction the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

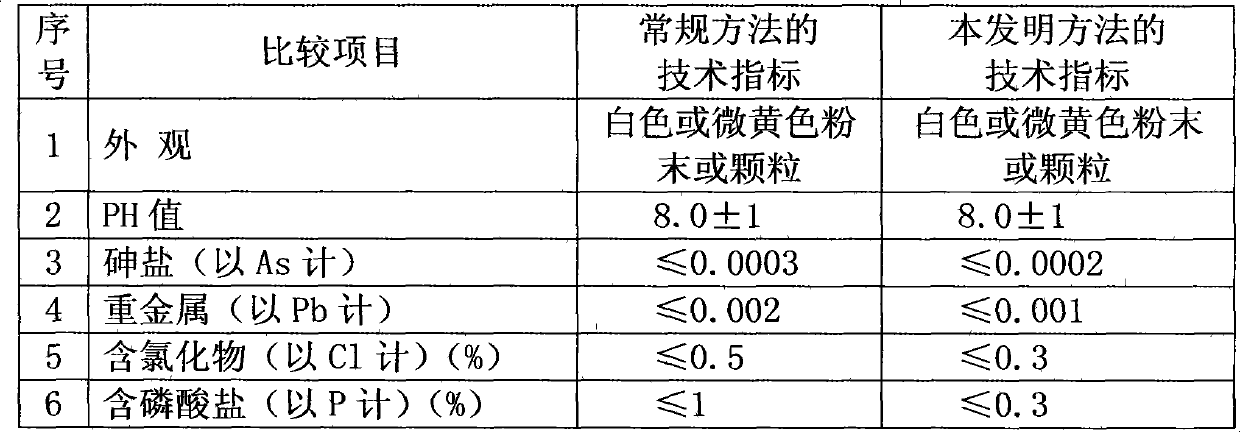

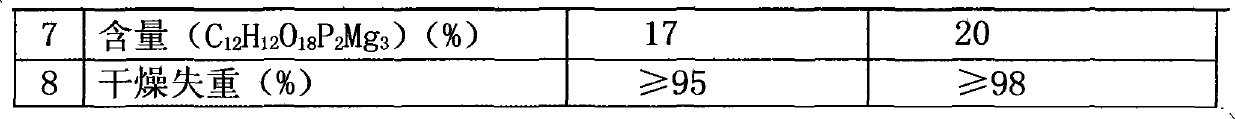

Image

Examples

Embodiment 1

[0016] Embodiment one: a kind of preparation method of vitamin C phosphate sodium, comprises the following processing steps:

[0017] (1) Adding 100Kg vitamin C, 6Kg anhydrous calcium chloride, and 100Kg deionized water into a 500L reaction kettle at -10°C, stirred for 1 hour, then added dropwise an aqueous sodium hydroxide solution with a concentration of 30%, and adjusted the pH to 6. Then add 50Kg of sodium trimetaphosphate, keep the temperature at 25°C, and react for 3 hours, and the obtained reactant is vitamin C ester calcium;

[0018] (2) Ascorbic acid ester calcium is added in the 500L bucket cleaner and washed with water, and then the pH is adjusted to 1.5 with hydrochloric acid, and the reactant obtained is vitamin C phosphate;

[0019] (3) Carry out membrane filtration with vitamin C phosphate through the microtube type dynamic membrane filter, the temperature of the microtube type dynamic membrane filter inlet is 100 ℃, the temperature of the microtube type dynamic...

Embodiment 2

[0028] Embodiment two: a kind of preparation method of vitamin C phosphate sodium, comprises the following processing steps:

[0029] (1) 100Kg vitamin C, 30Kg anhydrous calcium chloride, and 700Kg deionized water are added into a 1000L reaction kettle at 20°C, stirred for 2 hours, then added dropwise with a 50% aqueous sodium hydroxide solution to adjust the pH to 11 , then add 150Kg of sodium trimetaphosphate, keep the temperature at 45°C, react for 5 hours, and the reactant obtained is vitamin C ester calcium;

[0030] (2) Ascorbic acid ester calcium is added in the 1000L bucket cleaner and washed with water, and then the pH is adjusted to 3.5 with hydrochloric acid, and the reactant obtained is ascorbic acid phosphate;

[0031] (3) Carry out membrane filtration with vitamin C phosphate through the microtube type dynamic membrane filter, the temperature of the microtube type dynamic membrane filter inlet is 120 ℃, the temperature of the microtube type dynamic membrane filte...

Embodiment 3

[0036] Embodiment three: a kind of preparation method of vitamin C phosphate sodium, comprises the following processing steps:

[0037] (1) Adding 100Kg vitamin C, 20Kg anhydrous calcium chloride, and 600Kg deionized water into an 800L reaction kettle with a temperature of 10°C, stirred for 1.5 hours, then added dropwise an aqueous solution of sodium hydroxide with a concentration of 40%, and adjusted the pH to 9 , then add 100Kg of sodium trimetaphosphate, keep the temperature at 35°C, and react for 4 hours, and the obtained reactant is vitamin C ester calcium;

[0038](2) Ascorbic acid ester calcium is added in the 800L bucket cleaner and washed with water, then the pH is adjusted to be 2.5 with hydrochloric acid, and the reactant obtained is ascorbic acid phosphate;

[0039] (3) Carry out membrane filtration with vitamin C phosphate through the microtube type dynamic membrane filter, the temperature of the microtube type dynamic membrane filter inlet is 110 ℃, the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com