Preparation method of vitamin C magnesium ascorbyl phosphate

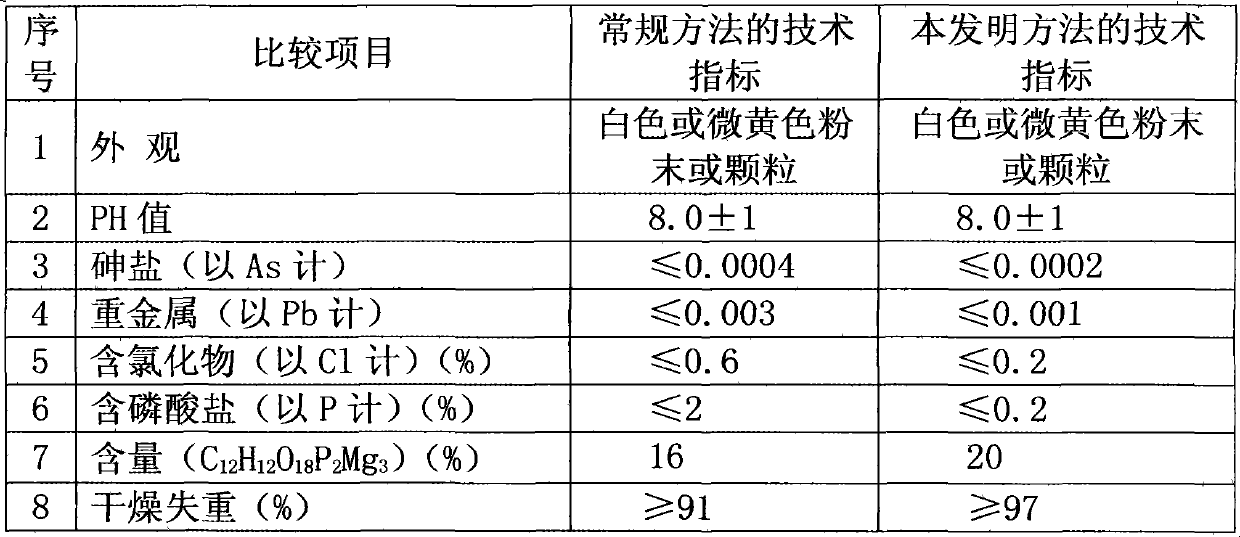

A technology of magnesium phosphate and vitamin, applied in the field of preparation of vitamin C derivatives, can solve the problems of difficulty in product separation and purification, low total product yield, complex synthesis process, etc., and achieves high impurity removal efficiency, simple process and simplified operation. effect of the program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment one: a kind of preparation method of vitamin C magnesium phosphate, comprises the following processing steps:

[0015] (1) Add 110Kg vitamin C, 8.8Kg anhydrous calcium chloride, and 110Kg deionized water into a 500L reaction kettle at -10°C, stir for 2 hours, then add dropwise a 30% sodium hydroxide aqueous solution to adjust the pH 5, then add 110Kg of sodium trimetaphosphate, keep the temperature at 25°C, and react for 2 hours, and the obtained reactant is vitamin C ester calcium;

[0016] (2) Ascorbic acid ester calcium is added in the 500L bucket cleaner and washed with water, and then the pH is adjusted to 1.5 with sulfuric acid, and the reactant obtained is ascorbic acid phosphate;

[0017] (3) Carrying out nanofiltration membrane filtration of vitamin C phosphate through a roll-type nanofiltration membrane filter, the temperature at the roll-type nanofiltration membrane filter inlet is 120° C., and the temperature at the roll-type nanofiltration membra...

Embodiment 2

[0023] Embodiment two: a kind of preparation method of vitamin C magnesium phosphate, comprises the following processing steps:

[0024] (1) 110Kg vitamin C, 44Kg calcium chloride anhydrous, 550Kg deionized water are added in the 1000L reaction kettle of 20 ℃, stirred for 3 hours, then added dropwise the sodium hydroxide aqueous solution of concentration 70%, regulating pH is 10.5, then Add 275Kg of sodium trimetaphosphate, keep the temperature at 45°C, and react for 6 hours, and the obtained reactant is vitamin C ester calcium;

[0025] (2) Ascorbic acid ester calcium is added in the 1000L bucket cleaner and washed with water, and then the pH is adjusted to 3.5 with sulfuric acid, and the reactant obtained is vitamin C phosphate;

[0026] (3) Vitamin C phosphate is carried out nanofiltration membrane filtration through the roll type nanofiltration membrane filter, the temperature of the roll type nanofiltration membrane filter inlet is 140 ℃, and the temperature of the roll t...

Embodiment 3

[0029] Embodiment three: a kind of preparation method of vitamin C magnesium phosphate, comprises the following processing steps:

[0030] (1) 110Kg vitamin C, 22Kg anhydrous calcium chloride, 330Kg deionized water are added in the 800L reaction kettle of 10 ℃,, stir for 2.5 hours, then add dropwise the sodium hydroxide aqueous solution of concentration 60%, adjust pH to be 8, Then add 150Kg of sodium trimetaphosphate, keep the temperature at 35°C, and react for 4 hours, and the obtained reactant is vitamin C phosphate;

[0031] (2) Ascorbic acid phosphate is added in the 800L bucket cleaner and washed with water, and then the pH is adjusted to 2.5 with sulfuric acid, and the reactant obtained is ascorbic acid phosphate;

[0032] (3) Carry out nanofiltration membrane filtration with vitamin C phosphate through the roll-type nanofiltration membrane filter, the temperature of the roll-type nanofiltration membrane filter inlet is 130 ℃, and the temperature of the roll-type nanofi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com