Low-temperature low-conductivity polyurethane foam, raw material composition, combined polyether and preparation method thereof

A technology of combining polyether and raw materials, which is applied in the field of polyurethane, can solve the problems of poor thermal insulation effect, high thermal conductivity of all-water foaming agent, environmental damage, etc., and achieve the effects of low GWP value, saving dosage, and high dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

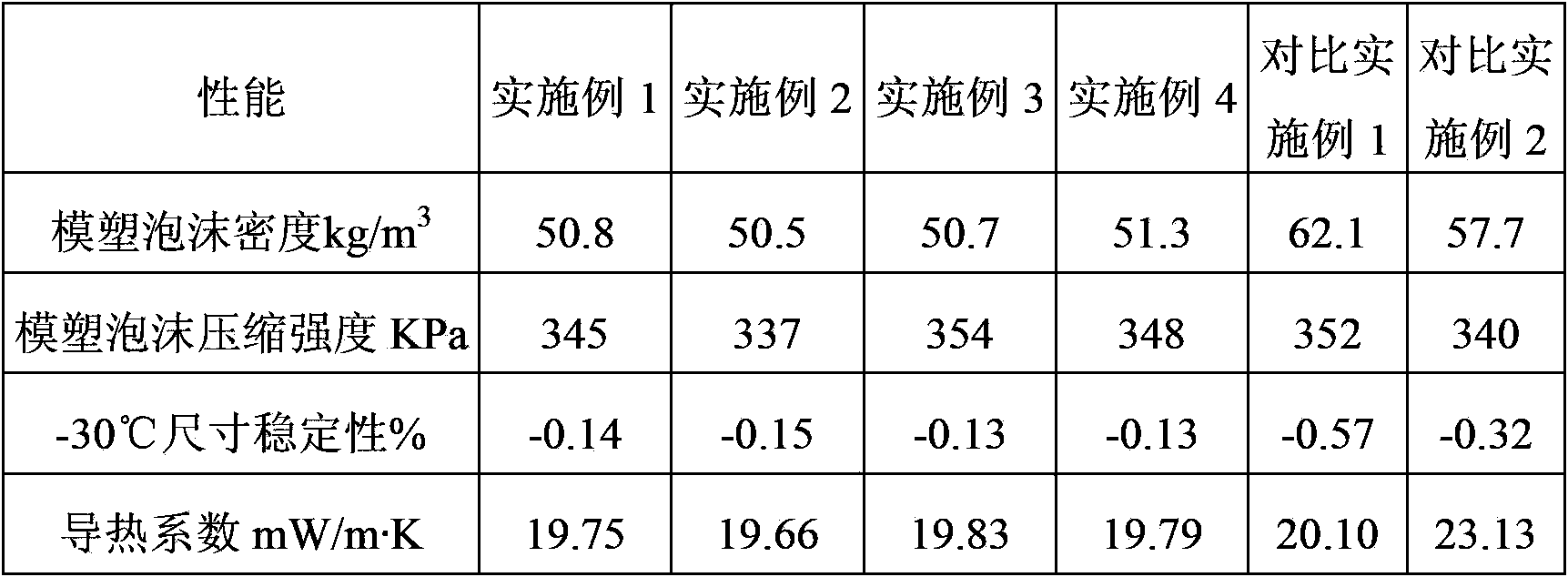

Examples

Embodiment 1

[0048] (1) Preparation of combined polyether:

[0049] 30 parts of polyether polyol 6207, 40 parts of polyether polyol 8307, 20 parts of polyether polyol DV125, 10 parts of polyester polyol PS3152, 2.0 parts of surfactant B8532, 0.6 parts of N,N-dimethylcyclohexyl Amine, 0.5 parts of catalyst TMR-2, 1.0 parts of N,N-dimethylbenzylamine, 1.8 parts of deionized water and 25 parts of HFC-245fa.

[0050] Put various raw materials into a closed container according to the above formula, and stir for 20 minutes under the condition of a rotation speed of 500 rpm at room temperature to prepare a composite polyether.

[0051] (2) Preparation of low-temperature low-conductivity polyurethane foam:

[0052] Pour the combined polyether and isocyanate 44V20 in Example 1 into a container at a mass ratio of 1:1, and stir electrically at a speed of 3000rpm for 8 seconds, and pour the evenly mixed liquid into a mold with a constant temperature of 50°C. Close the mold and ripen for 0.5 hour to ...

Embodiment 2

[0054] (1) Preparation of combined polyether:

[0055] 50 parts of polyether polyol SA460, 20 parts of polyether polyol 8307, 15 parts of polyether polyol 303, 15 parts of polyester polyol PS3152, 2.5 parts of surfactant L-6860, 0.3 parts of catalyst DABCOBX405, 0.2 parts of catalyst TMR -2. 1.5 parts of N,N-dimethylbenzylamine, 2.5 parts of deionized water and 10 parts of HFC-245fa.

[0056] Put various raw materials into a closed container according to the above formula, and stir for 20 minutes under the condition of a rotation speed of 500 rpm at room temperature to prepare a composite polyether.

[0057] (2) Preparation of low-temperature low-conductivity polyurethane foam:

[0058] Pour the combined polyether and isocyanate 44V20 in Example 2 into the container according to the mass ratio of 1:1.1, stir it electrically at a speed of 3000rpm for 8 seconds, and pour the evenly mixed liquid into a mold with a constant temperature of 40°C. Close the mold and ripen for 0.5 h...

Embodiment 3

[0060] (1) Preparation of combined polyether:

[0061] 45 parts of polyether polyol 6207, 35 parts of polyether polyol 8307, 15 parts of polyether polyol DV125, 5 parts of polyester polyol PS3152, 3.0 parts of surfactant B8532, 0.7 parts of N,N-dimethylcyclohexyl Amine, 0.4 parts of catalyst TMR-2, 1.2 parts of N,N-dimethylbenzylamine, 1.5 parts of deionized water and 30 parts of HFC-245fa.

[0062] Put various raw materials into a closed container according to the above formula, and stir for 20 minutes under the condition of a rotation speed of 500 rpm at room temperature to prepare a composite polyether.

[0063] (2) Preparation of low-temperature low-conductivity polyurethane foam:

[0064] Pour the combined polyether and isocyanate PM200 in Example 3 into a container at a mass ratio of 1:1.2, and stir it electrically at a speed of 3000rpm for 8 seconds, and pour the evenly mixed liquid into a mold with a constant temperature of 45°C. Close the mold and ripen for 0.5 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com