Phenolic resin molding material, molded product, and electrical/electronic part

A technology of phenolic resin and molding materials, which is applied in the field of phenolic resin molding materials, molded products and electrical and electronic components, and can solve problems such as low thermal conductivity and misoperation of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

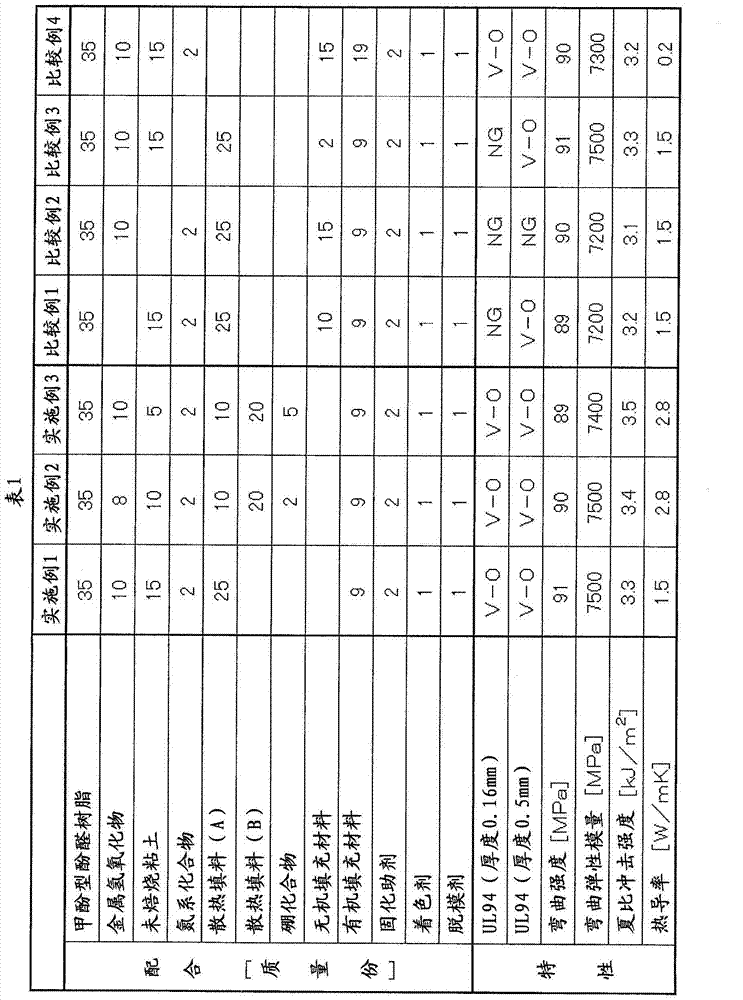

Embodiment 1~3、 comparative example 1~4)

[0060] The raw material mixture having the composition described in Table 1 was melted and kneaded for 3 minutes with a heating roll at 90°C, taken out, pulverized, and pulverized into pellets to obtain a molding material.

[0061] (Evaluation method)

[0062] (1) Flame resistance

[0063] Using the molding materials obtained in Examples and Comparative Examples, test pieces of 125 mm×12.5 mm×0.16 mm and 125 mm×12.5 mm×5.0 mm were produced by compression molding. The molding conditions were mold temperature of 175° C. and curing time of 2 minutes. The flame resistance test was implemented based on UL94 using these test pieces.

[0064] (2) Mechanical strength (bending strength, flexural modulus and Charpy impact strength)

[0065] Using the molding materials obtained in Examples and Comparative Examples, bending test pieces and Charpy impact test pieces were produced by transfer molding. The molding conditions were mold temperature of 175° C. and curing time of 3 minutes. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com