A heat-reflecting heat-insulating coating with high pollution resistance and water resistance

A heat-insulating paint and pollution-resistant technology, applied in the field of paint, can solve the problems of attenuation of heat-insulating effect of reflective heat-insulating paint, poor water resistance, poor pollution resistance, rare reflective heat-insulating paint, etc., and achieve obvious and good reflective heat-insulating effect. Excellent adhesion and anti-settling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

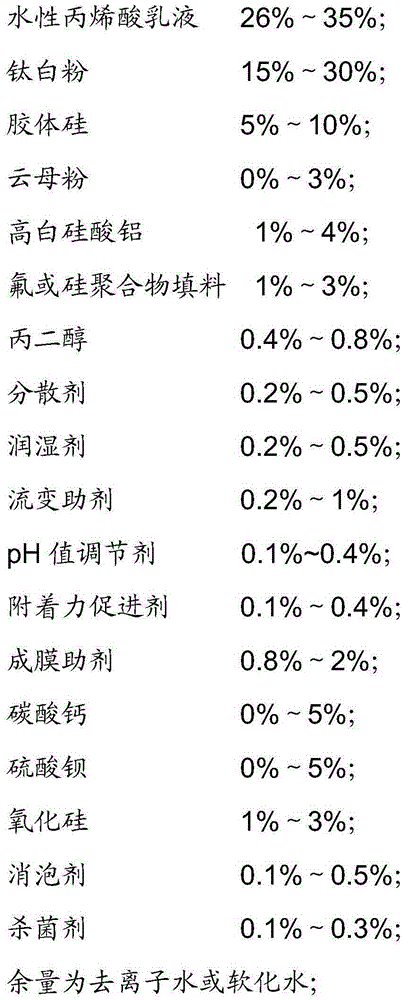

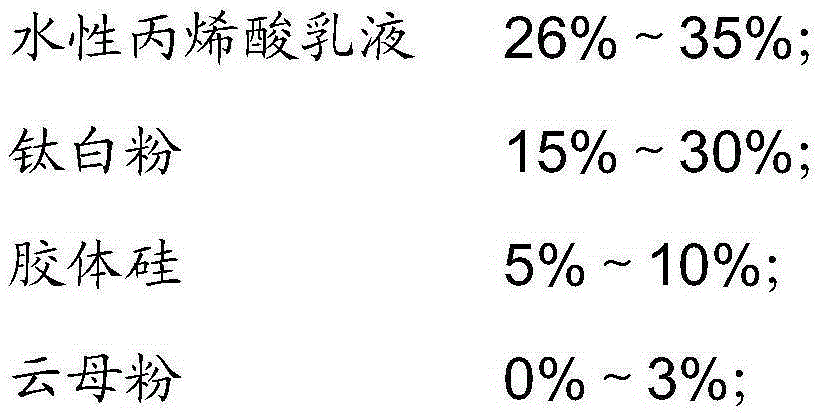

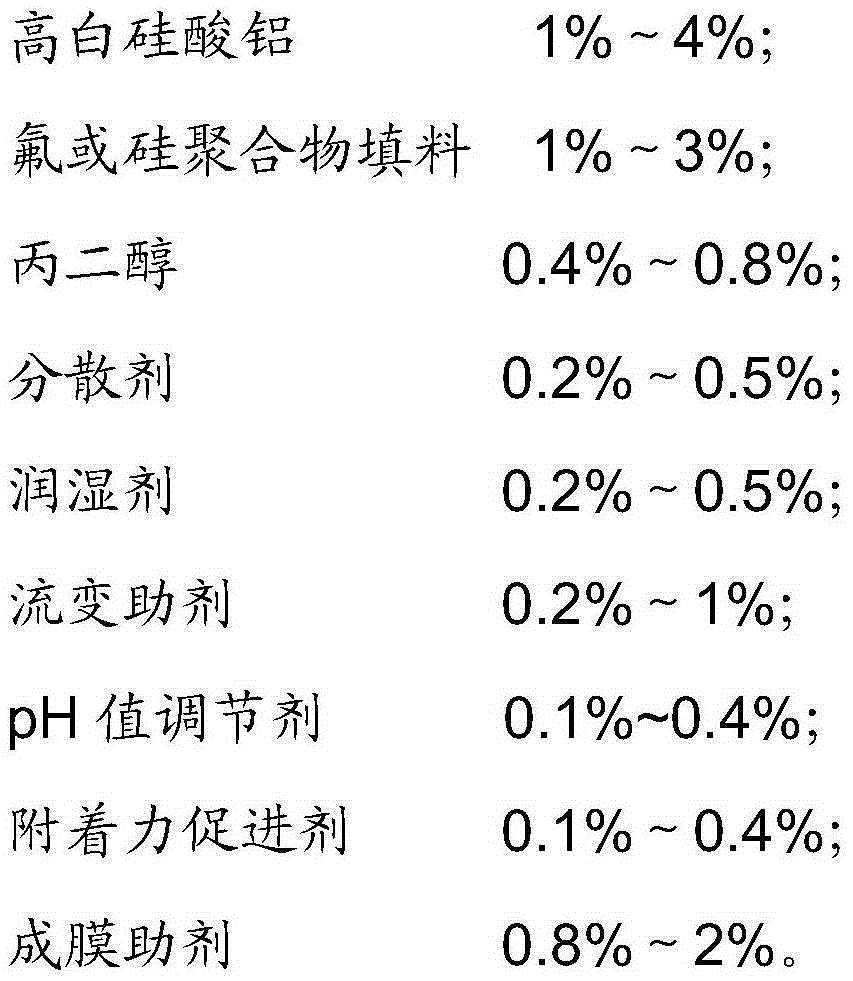

[0040] 1. The composition and proportion are as follows:

[0041]

[0042] Among them, the water-based acrylic emulsion adopts Rohm and Haas 261P pure acrylic emulsion.

[0043] Two, the preparation method is as follows:

[0044] (1) Add dispersant, bactericide, defoamer, adhesion promoter, wetting agent, rheology additive A, film-forming aid and pH regulator into deionized water and stir evenly;

[0045] (2) Continue to add various paint filler components (titanium dioxide, high white aluminum silicate, barium sulfate, calcium carbonate, silicon oxide, mica powder) and stir evenly;

[0046] (3) Continue to add water-based acrylic emulsion and stir evenly, then add spherical silicone resin and stir evenly;

[0047] (4) Finally, add colloidal silicon, propylene glycol, rheological additive B, and rheological additive C, and stir evenly.

[0048] 3. Test results

[0049] After testing, the full-band reflectance of the coating film reaches 0.87, the full-band emissivity re...

Embodiment 2

[0051] 1. The composition and proportion are as follows:

[0052]

[0053]

[0054] Among them, the water-based acrylic emulsion adopts Rohm and Haas 261P pure acrylic emulsion.

[0055] Two, the preparation method is as follows:

[0056] The coating preparation method is carried out with reference to the method of Example 1.

[0057] 3. Test results

[0058] After testing, the full-band reflectance of the coating film reaches 0.87, the full-band emissivity reaches 0.90, the coating heat insulation temperature difference reaches 25.3°C, and the pollution resistance is 3.2%. After the coating film is polluted, it can be cleaned with clean water without wiping marks on the surface .

Embodiment 3

[0060] 1. The composition and proportion are as follows:

[0061]

[0062]

[0063] Among them, the water-based acrylic emulsion adopts Rohm and Haas 261P pure acrylic emulsion.

[0064] Two, the preparation method is as follows:

[0065] The coating preparation method is carried out with reference to the method of Example 1.

[0066] 3. Test results

[0067] After testing, the full-band reflectance of the coating film reaches 0.88, the full-band emissivity reaches 0.91, the coating heat insulation temperature difference reaches 25.6°C, and the pollution resistance is 1%. After the coating film is polluted, it can be cleaned with clean water without wiping marks on the surface .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com