Vehicle engine cooling liquid

A technology of automobile engine and coolant, which is applied in the field of coolant, can solve the problems of high production cost, less antifreeze, and difficulty in wide application, and achieve the effect of good anti-corrosion effect, stable performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

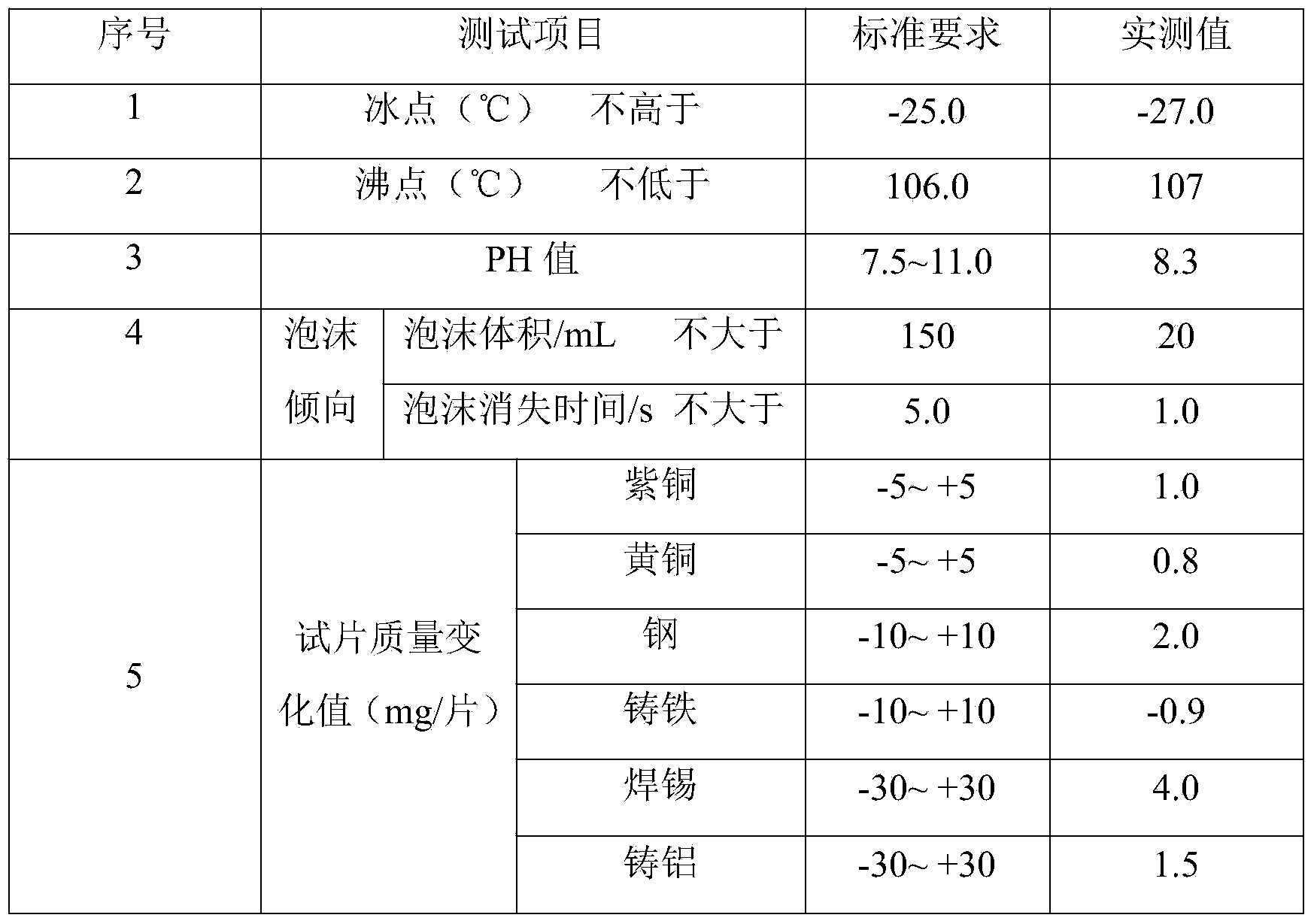

Embodiment 1

[0019] An automobile engine coolant, the additive composition is composed according to the following mass percentage ratios,

[0020] For No.-25 antifreeze:

[0021] Ethylene glycol 42%, benzotriazole 0.15%, sodium benzoate 0.05%, sebacic acid 0.5%, azelaic acid 0.1%, sodium metasilicate 0.5%, γ-(sodium sulfonate) propylsiloxane 0.2%, defoamer 0.001%, potassium hydroxide 0.05%, dye 0.002%, deionized water 56.447%.

[0022] Preparation:

[0023] 1. Take an appropriate amount of water, first add sodium metasilicate to dissolve, then add silicate stabilizer and stir, after dissolving, add sodium benzoate, stir, dissolve and set aside;

[0024] 2. Take each raw material according to the formula, first add ethylene glycol into the reaction kettle, then add sebacic acid, azelaic acid and benzotriazole, after stirring evenly, slowly add the solution in step 1, stir evenly; finally add The cooling liquid is obtained after the other raw materials are fully stirred evenly.

[0025] ...

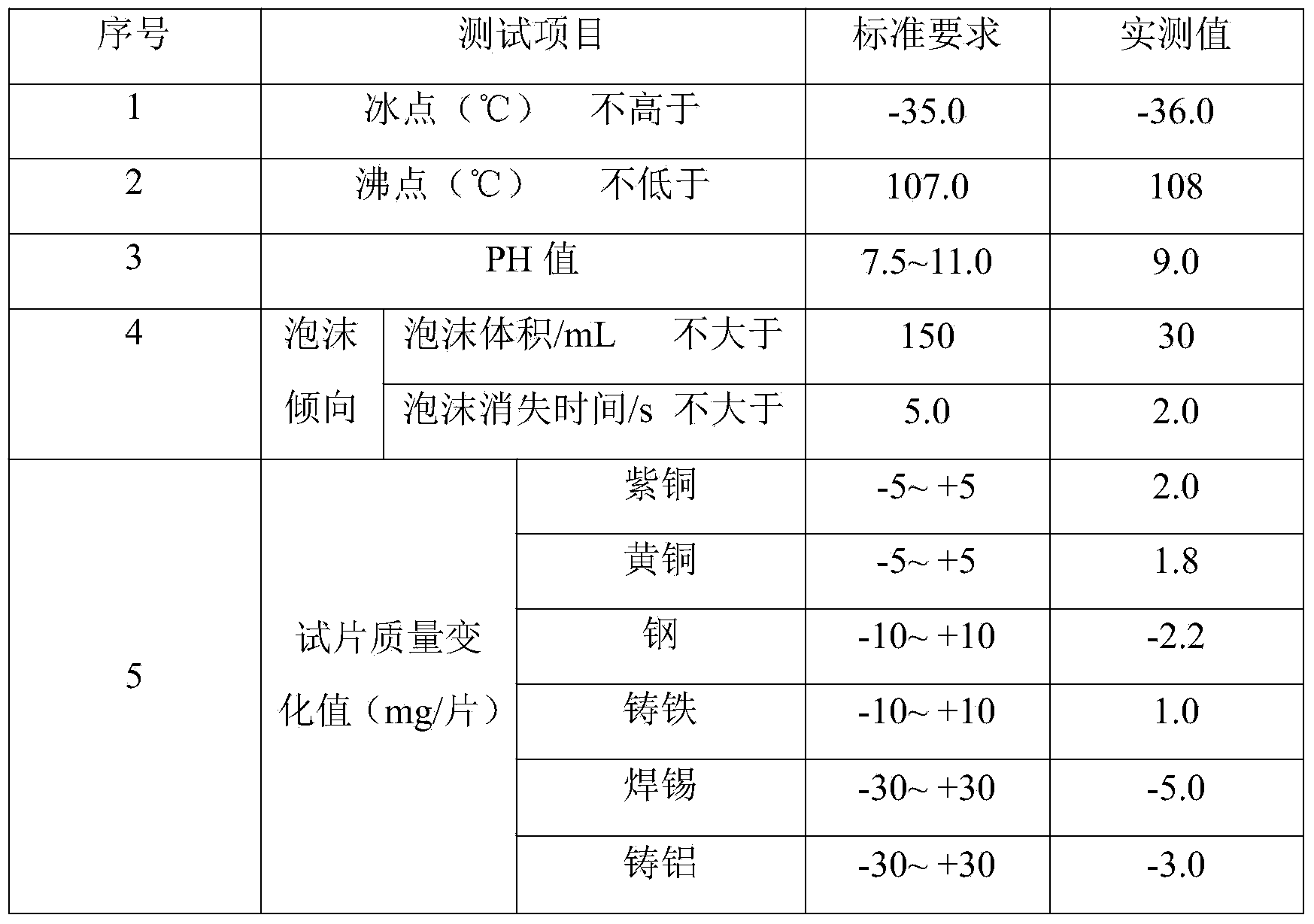

Embodiment 2

[0028] A kind of automobile engine coolant, described additive composition is made up according to following mass percentage ratio, is No.-35:

[0029] Ethylene glycol 50%, benzotriazole 0.2%, sodium benzoate 0.06%, sebacic acid 0.8%, azelaic acid 0.4%, sodium metasilicate 0.7%, γ-(sodium sulfonate) propylsiloxane 0.4%, defoamer 0.005%, potassium hydroxide 0.1%, dye 0.002%, deionized water 47.333%.

[0030] Preparation:

[0031] 1. Take an appropriate amount of water, first add sodium metasilicate to dissolve, then add silicate stabilizer and stir, after dissolving, add sodium benzoate, stir, dissolve and set aside;

[0032] 2. Take each raw material according to the formula, first add ethylene glycol into the reaction kettle, then add sebacic acid, azelaic acid and benzotriazole, after stirring evenly, slowly add the solution in step 1, stir evenly; finally add The cooling liquid is obtained after the other raw materials are fully stirred evenly.

[0033] According to NB / S...

Embodiment 3

[0036] A kind of automobile engine coolant, described additive composition is made up according to following mass percentage ratio, is -40 number:

[0037]

[0038]

[0039] According to NB / SH / T0521-2010 standard for glassware corrosion test, the results are as follows:

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com