High-base-number naphthenic acid composite calcium-magnesium detergent, preparation method thereof and lubricating oil composition

A high base value naphthene and detergent technology, which is applied in lubricating compositions, additives, petroleum industry, etc., can solve the problems of slow development and poor cleaning performance, and achieve low ash content, good acid neutralization ability, and high base value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

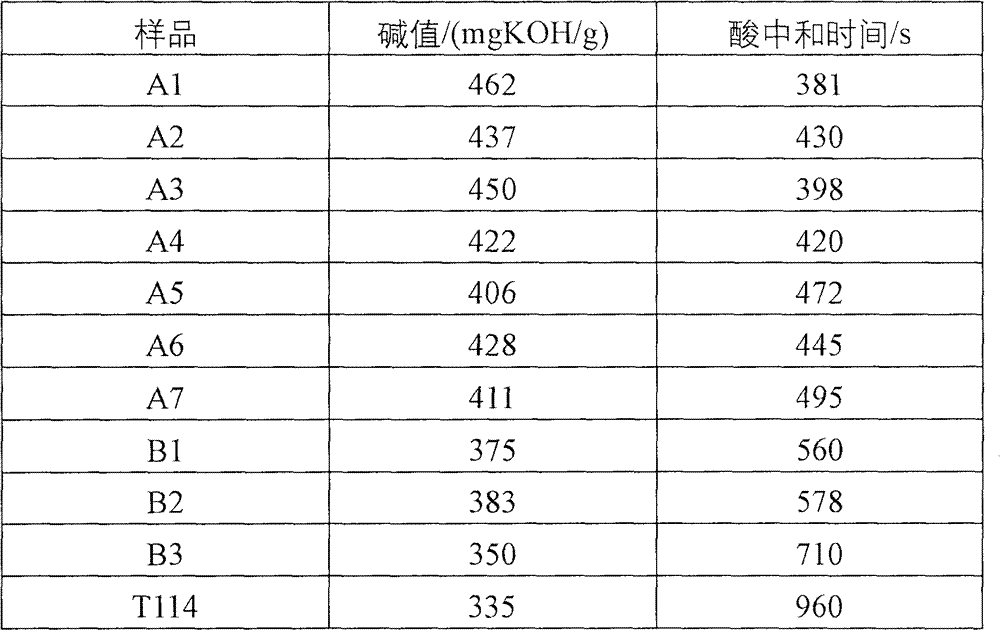

Examples

Embodiment 1

[0040]Add 150 milliliters of xylenes in the reactor, 35 grams of 150SN neutral oils, 10 grams of water, 10 grams of calcium oxide, 65 grams of naphthenic acid (pure acid value 118mgKOH / g, acid content 72%), control reaction temperature at 60 ℃, after 60 minutes of neutralization reaction, neutral calcium naphthenate is generated. Add 15 grams of magnesium oxide, 20 grams of methanol, 10 grams of dodecylbenzenesulfonic acid, and 15 grams of ethylenediamine, control the reaction temperature to 55°C, and feed carbon dioxide at a ventilation rate of about 100ml / min. When the absorption rate of carbon dioxide reaches 90% of the theoretical value, add 15 grams of magnesia, and pass into carbon dioxide to carry out the secondary carbonation reaction. When the absorption rate of carbon dioxide reaches 90% of the theoretical value, the reaction ends. Heat up to 130°C for dealcoholization and water, then add solvent to dilute and centrifuge, put the centrifuged flash product into a dist...

Embodiment 2

[0042] Add 150 milliliters of xylenes in the reactor, 35 grams of 150SN neutral oil, 10 grams of water, 10 grams of calcium oxide, 65 grams of naphthenic acid (pure acid value 118mgKOH / g, acid content 72%), control reaction temperature at 50 ℃, after 60 minutes of neutralization reaction, neutral calcium naphthenate is generated. Add 15 grams of magnesium oxide, 20 grams of methanol, 10 grams of dodecylbenzenesulfonic acid, and 15 grams of ethylenediamine, control the reaction temperature to 50°C, and feed carbon dioxide at a ventilation rate of about 100ml / min. When the absorption rate of carbon dioxide reaches 90% of the theoretical value, add 15 grams of magnesia, and pass into carbon dioxide to carry out the secondary carbonation reaction. When the absorption rate of carbon dioxide reaches 90% of the theoretical value, the reaction ends. Heat up to 130°C for dealcoholization and water, then add solvent to dilute and centrifuge, put the centrifuged flash product into a dist...

Embodiment 3

[0044] Add 150 milliliters of xylenes in the reactor, 35 grams of 150SN neutral oils, 15 grams of water, 15 grams of calcium oxide, 65 grams of naphthenic acid (pure acid value 118mgKOH / g, acid content 72%), control reaction temperature at 60 ℃, after 60 minutes of neutralization reaction, neutral calcium naphthenate is generated. Add 15 grams of magnesium oxide, 15 grams of methanol, 6 grams of dodecylbenzenesulfonic acid, and 20 grams of triethanolamine, control the reaction temperature at 55 ° C, and feed carbon dioxide at a ventilation rate of about 100 ml / min, and the amount of feed reaches the theoretical value When the carbon dioxide absorption rate reaches 90% of the theoretical value, the reaction ends. Heat up to 130°C for dealcoholization and water, then add solvent to dilute and centrifuge, put the centrifuged flash product into a distillation bottle with a decompression facility, first raise the temperature to 120°C for atmospheric distillation, the heating rate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com