Preparation method of micro/nano dendritic silver super-hydrophilicity film and application of film in surface enhanced Raman substrate

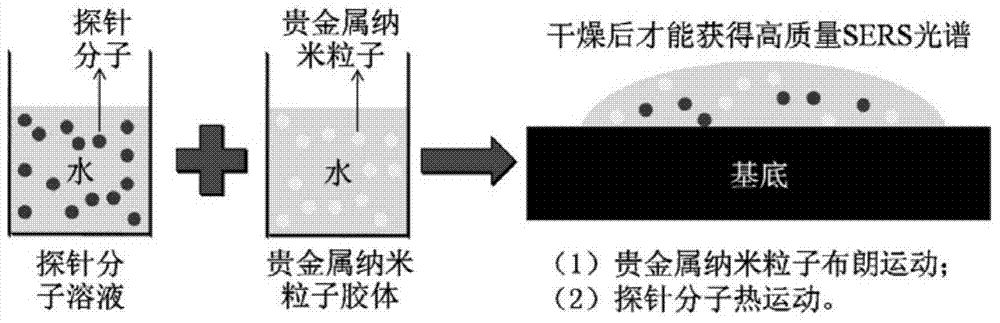

A micro-nano, super-hydrophilic technology, applied in the direction of nanotechnology, Raman scattering, liquid chemical plating, etc., can solve the problems of high preparation cost, lack of fast, on-site and real-time, and inability to effectively obtain SERS signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

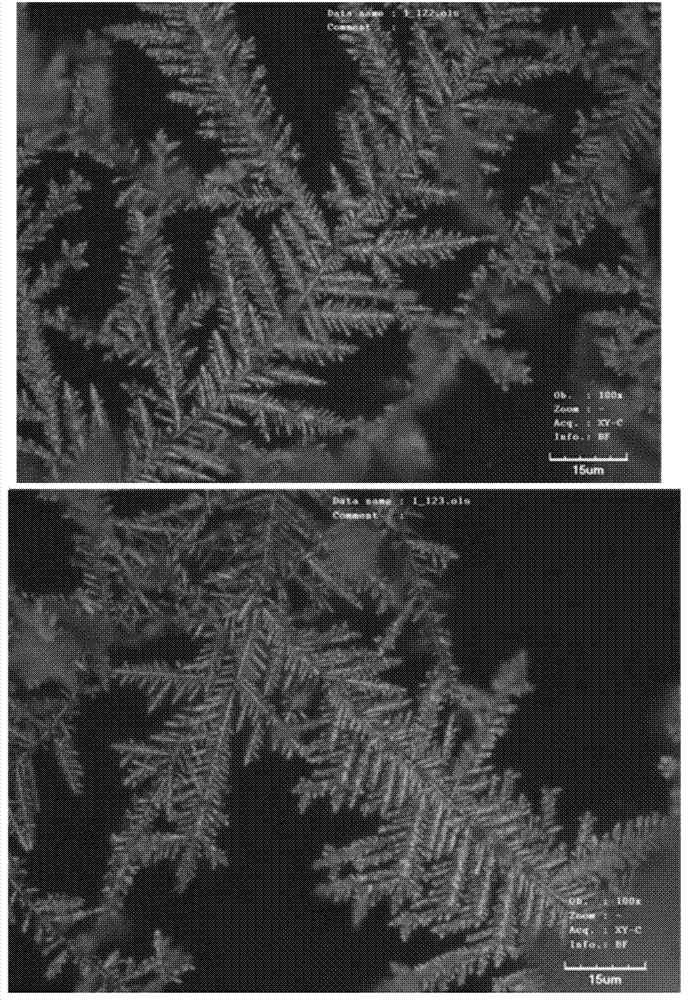

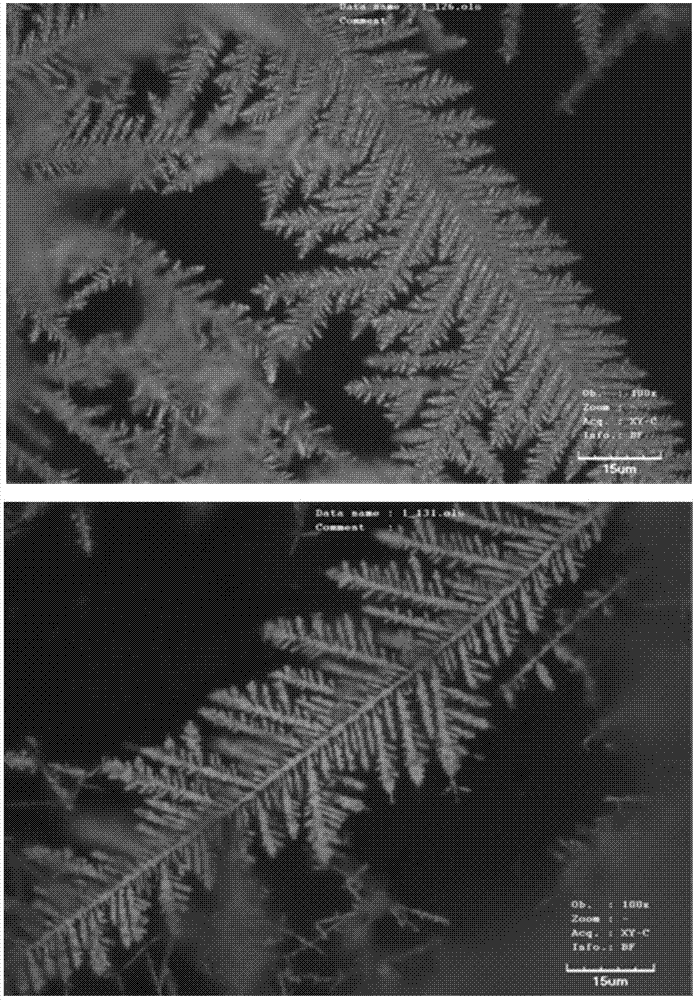

Embodiment 1

[0033] Place a flat high-purity aluminum sheet with a thickness of 300 μm and a purity of 99.999% after ultrasonic cleaning and drying with acetone on a glass substrate, and immerse the high-purity aluminum sheet and the glass substrate together in 100ml of silver nitrate solution with a molar concentration of 1mmol / L and 20ml of dilute silver nitrate solution with a concentration of 38%. in a mixture of sulfuric acid. Self-assembled and grown at room temperature to avoid vibration. After about 48 hours, a micro-nano dendritic silver film was grown on the glass substrate with a high-purity aluminum sheet, and then the micro-nano dendritic silver film was deposited by the uniform drop method of the liquid level. The substrate was taken out from the solution and separated from the remaining aluminum sheet, rinsed with ultrapure water several times and then dried to obtain a micro-nano-dendritic silver super-hydrophilic surface enhancement that can be used for rapid, on-site, and ...

Embodiment 2

[0035] Place a flat high-purity aluminum sheet with a thickness of 300 μm and a purity of 99.999% after ultrasonic cleaning and drying with acetone on a glass substrate, and immerse the high-purity aluminum sheet and the glass substrate together in 100ml of a silver nitrate solution with a molar concentration of 2mmol / L and 20ml of a dilute solution with a concentration of 38%. in the sulfuric acid mixture. Self-assembled and grown at room temperature to avoid vibration. After about 48 hours, a micro-nano dendritic silver film was grown on the glass substrate with a high-purity aluminum sheet, and then the micro-nano dendritic silver film was deposited by the uniform drop method of the liquid level. The substrate was taken out from the solution and separated from the remaining aluminum sheet, rinsed with ultrapure water several times and then dried to obtain a micro-nano-dendritic silver super-hydrophilic surface enhancement that can be used for rapid, on-site, and real-time tr...

Embodiment 3

[0037] Place a flat high-purity aluminum sheet with a thickness of 300 μm and a purity of 99.999% after ultrasonic cleaning and drying with acetone on a glass substrate, and immerse the high-purity aluminum sheet and the glass substrate together in 100ml of a molar concentration of 3mmol / L silver nitrate solution and 20ml of a 38% concentration of dilute in the sulfuric acid mixture. Self-assembled and grown at room temperature to avoid vibration. After about 48 hours, a micro-nano dendritic silver film was grown on the glass substrate with a high-purity aluminum sheet, and then the micro-nano dendritic silver film was deposited by the uniform drop method of the liquid level. The substrate was taken out from the solution and separated from the remaining aluminum sheet, rinsed with ultrapure water several times and then dried to obtain a micro-nano-dendritic silver super-hydrophilic surface enhancement that can be used for rapid, on-site, and real-time trace detection of substan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com