Dry overall shield insulating tubular bus

A tubular busbar, shielding insulation technology, applied in the direction of insulated cables, insulated conductors, organic insulators, etc., can solve the problems of processing insulation layer, damage, and inability to use common bending angles, etc., to achieve good electrical insulation performance, excellent heat resistance, The effect of excellent water repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

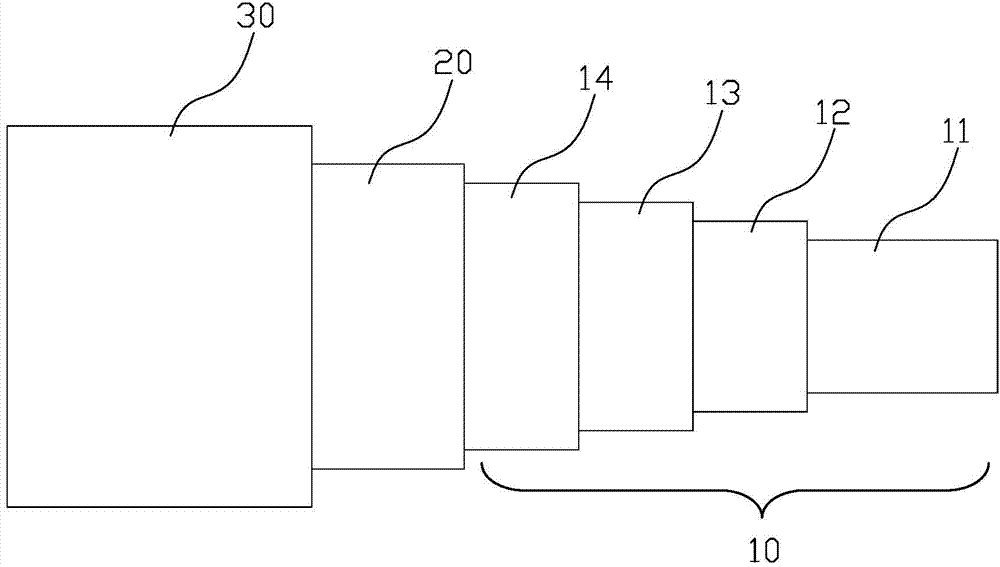

[0008] Combine below figure 1 , the present invention is described in further detail.

[0009] A dry-type fully shielded insulated tubular busbar, comprising a tubular conductive core 11, the conductive core 11 is coated with a first semi-conductive shielding layer 12, an insulating layer 13, a second semi-conductive shielding layer 14, and a grounding shielding layer in sequence from the inside to the outside 20. The outer protective layer 30, the insulating layer 13 is made of organic silica gel. The first semi-conductive shielding layer 12 is arranged on the outside of the conductive core 11 to uniform the electric field and avoid tip discharge caused by sharp corners or burrs on the surface of the conductive core 11; the second semi-conductive shielding layer 14 acts as an insulating shield. The materials of the first and second semi-conductive shielding layers 12 and 14 can adopt common settings. The gist of the present invention is to use organic silica gel as the insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com