High-voltage super-junction terminal structure

A junction terminal, high voltage technology, applied in the field of high voltage super junction terminal structure, can solve the problems of increasing chip production cost, poor electric field uniformity, increasing chip area, etc., to reduce ion pollution and charge accumulation, and avoid electric field concentration effect. , the effect of preventing charge imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

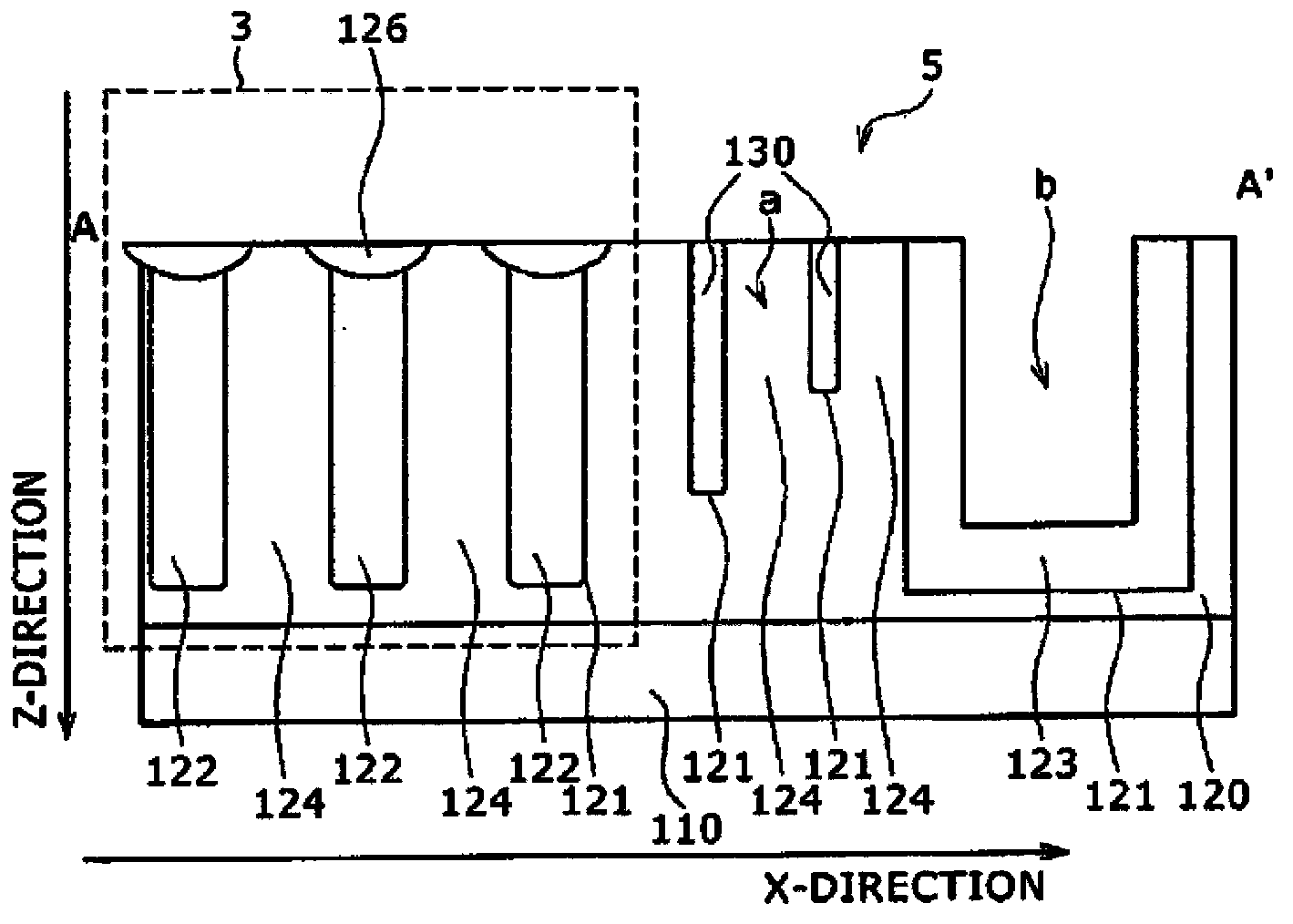

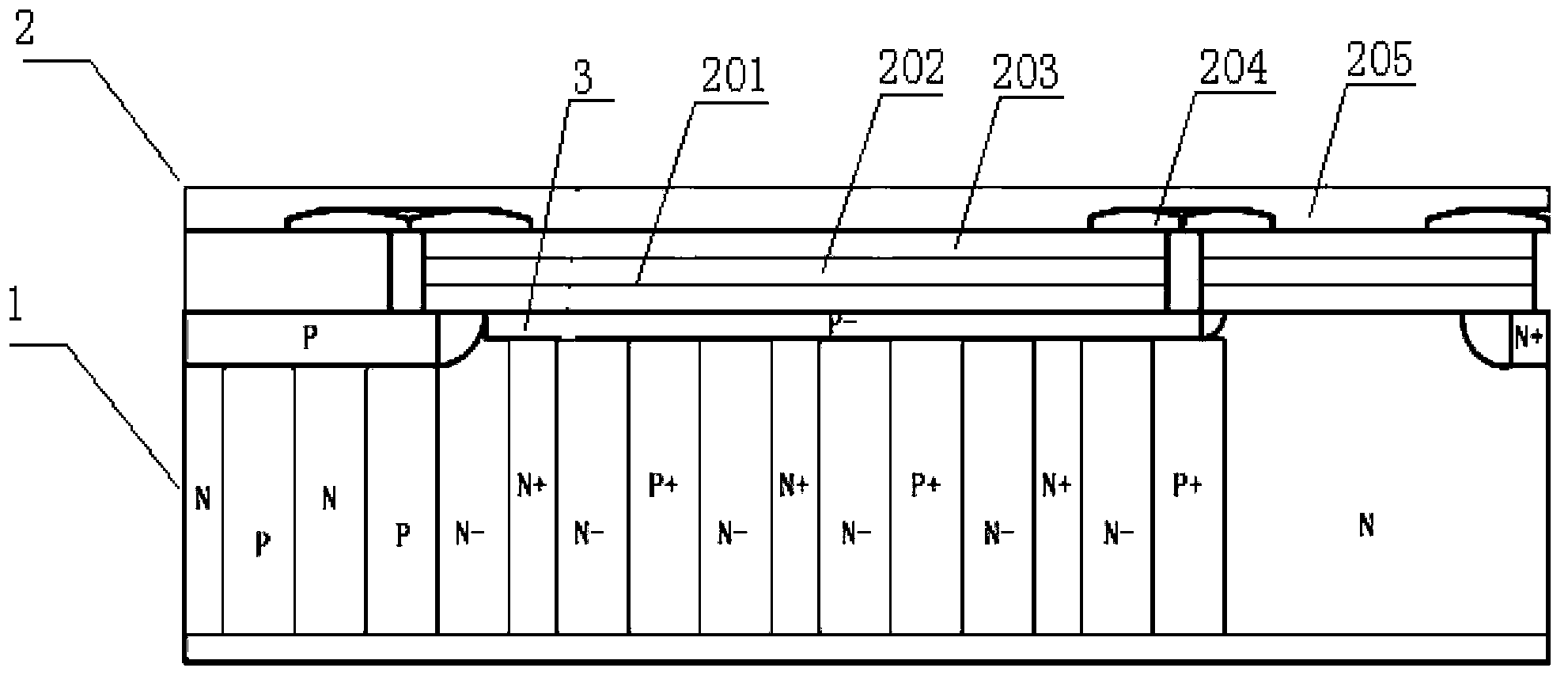

[0027] see figure 2 , the present invention provides a high-voltage super junction terminal structure, including a super junction region 1 composed of spaced P+, N-, N+ columns and a terminal surface structure 2 with a metal field plate and a SIPOS field plate, the super junction region 1 There is a layer of P-layer 3 between the terminal surface structure 2 and the terminal surface structure 2, and the surface of the silicon wafer of the terminal surface structure 2 is sequentially deposited with a high resistance SIPOS layer 201, SiO layer from bottom to top 2 layer 202 , low resistance SIPOS layer 203 , metal field plate 204 and nitrogen doped SIPOS layer 205 .

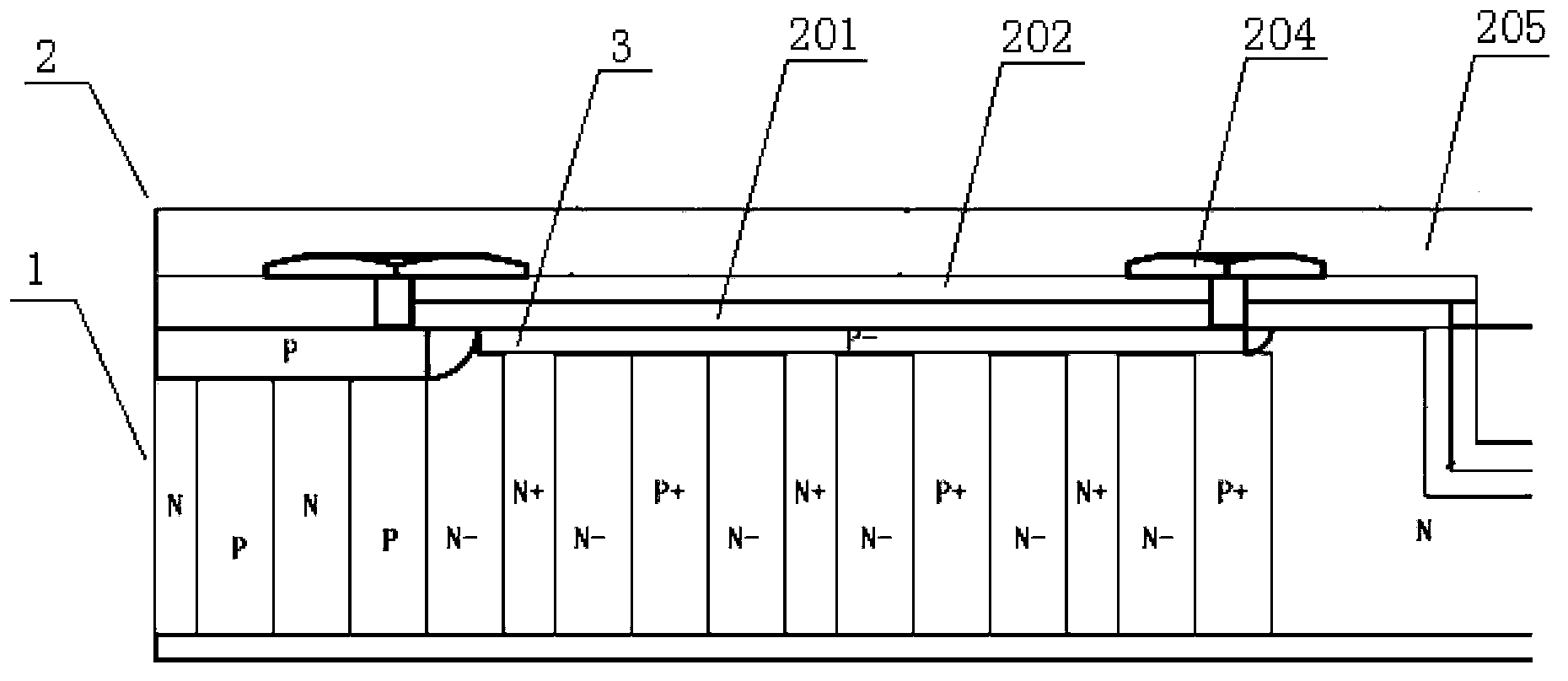

[0028] see image 3 , a high-voltage superjunction terminal structure provided by an embodiment of the present invention includes a superjunction region 1 composed of spaced P+, N-, and N+ columns and a terminal surface structure 2 with a metal field plate and a SIPOS field plate. There is a layer of P-layer 3 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com