Manufacturing method of chimney exhaust gas dust removal filter cloth

A manufacturing method and filter cloth technology, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of increasing the filtration area, reducing the filtration wind speed, unreasonable production and application, etc., and achieve high strength and running resistance The effect of reducing and meeting industrial emission requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

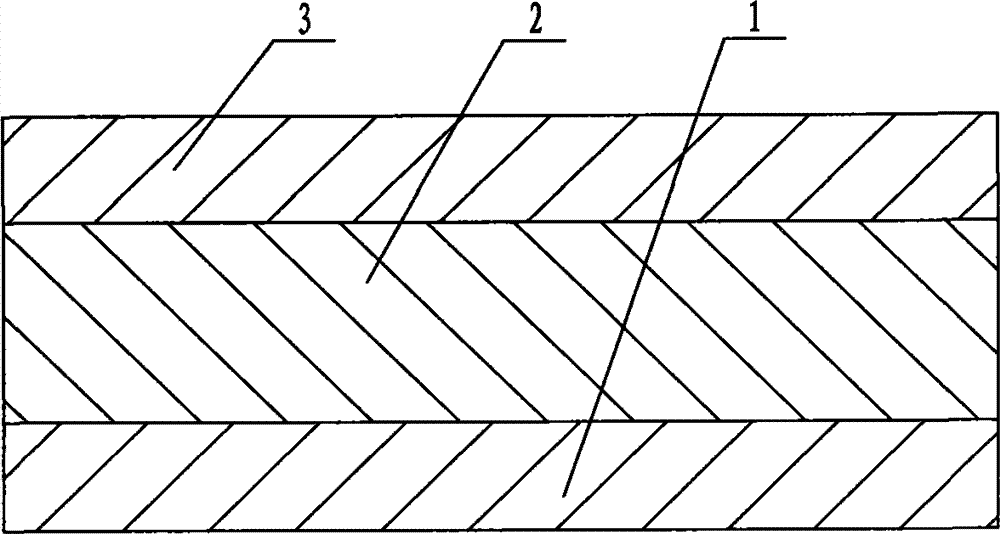

Embodiment 1

[0019] A method for manufacturing chimney exhaust gas dust removal filter cloth, comprising: using liquid crystal polyarylate fiber yarn to make a fabric layer 1 with a spatial network structure, and performing low-temperature plasma treatment on the fabric layer 1; The weaving process makes the liquid crystal polyarylate fiber into the filter material base 2, performs low-temperature plasma treatment on the filter material base 2, uses the knitting process to weave the fabric layer 1 and the filter material base 2 together; uses the spinning solution to use nanofiber electrospinning The spinning device carries out electrospinning, so that the spinning solution forms a charged jet stream, and the charged spinning solution jet stream is arranged on the surface of the filter material base layer 2 in a disordered manner after stretching, thinning, bending, and splitting. The nanofiber membrane 3 is formed. Due to the high-speed impact of the spinning solution and its own adhesive ...

Embodiment 2

[0022] A method for manufacturing chimney exhaust gas dust removal filter cloth, comprising: using liquid crystal polyarylate fiber yarn to make a fabric layer 1 with a spatial network structure, and performing low-temperature plasma treatment on the fabric layer 1; The weaving process makes the liquid crystal polyarylate fiber into the filter material base 2, performs low-temperature plasma treatment on the filter material base 2, uses the knitting process to weave the fabric layer 1 and the filter material base 2 together; uses the spinning solution to use nanofiber electrospinning The spinning device carries out electrospinning, so that the spinning solution forms a charged jet stream, and the charged spinning solution jet stream is arranged on the surface of the filter material base layer 2 in a disordered manner after stretching, thinning, bending, and splitting. The nanofiber membrane 3 is formed. Due to the high-speed impact of the spinning solution and its own adhesive ...

Embodiment 3

[0025] A method for manufacturing chimney exhaust gas dust removal filter cloth, comprising: using liquid crystal polyarylate fiber yarn to make a fabric layer 1 with a spatial network structure, and performing low-temperature plasma treatment on the fabric layer 1; The weaving process makes the liquid crystal polyarylate fiber into the filter material base 2, performs low-temperature plasma treatment on the filter material base 2, uses the knitting process to weave the fabric layer 1 and the filter material base 2 together; uses the spinning solution to use nanofiber electrospinning The spinning device carries out electrospinning, so that the spinning solution forms a charged jet stream, and the charged spinning solution jet stream is arranged on the surface of the filter material base layer 2 in a disordered manner after stretching, thinning, bending, and splitting. The nanofiber membrane 3 is formed. Due to the high-speed impact of the spinning solution and its own adhesive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com