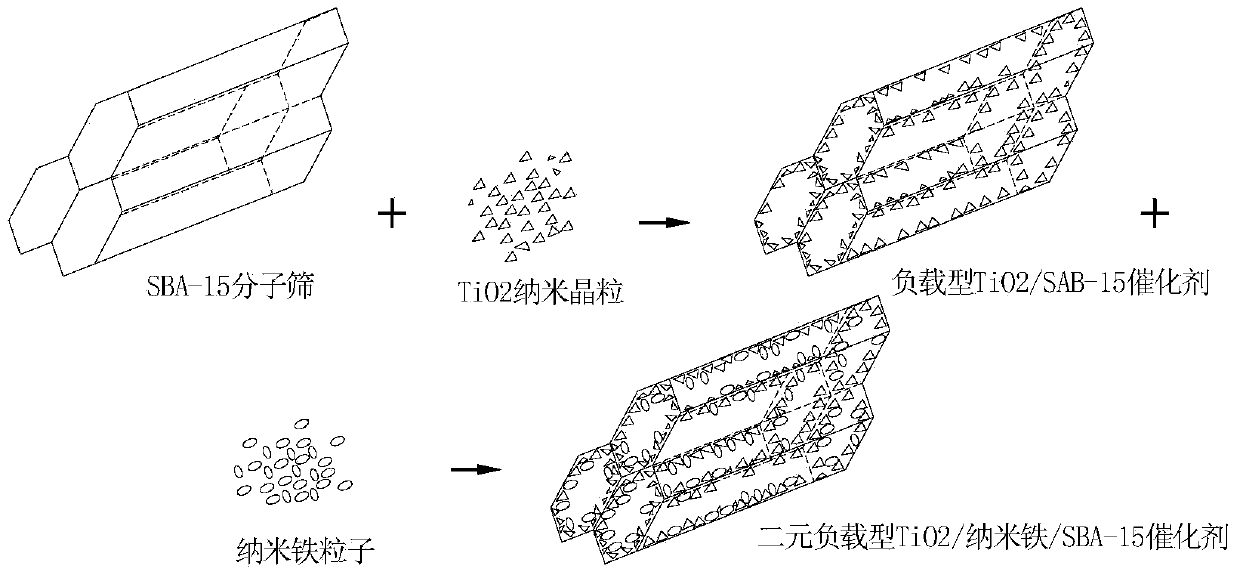

Preparation method of binary load-type TiO2/nano-iron/SBA-15 catalyst

A supported and catalyst technology, which is applied in the field of preparation of binary supported TiO2/nano-iron/SBA-15 catalysts, can solve the problems of high recombination rate of photogenerated carriers, expensive noble metals, and high cost, and achieve photocatalytic efficiency Improve and inhibit the effect of compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Binary supported TiO of the present invention 2 The preparation method of / nanometer iron / SBA-15 catalyst, this method comprises the following steps:

[0033] (1) Preparation of butyl titanate hydrolysis buffer

[0034] Add 4.26ml of concentrated hydrochloric acid with a mass fraction of 36% to 38% into a 500mL volumetric flask filled with anhydrous ethanol solvent to prepare a 0.1mol / L hydrochloric acid ethanol solution, which is recorded as butyl titanate hydrolysis buffer.

[0035] (2) Loaded TiO 2 / SBA-15 catalyst preparation

[0036] The volume ratio of reaction substances is: butyl titanate: absolute ethanol: butyl titanate hydrolysis buffer: distilled water + butyl titanate hydrolysis buffer = 10:10:20-50:2.1+5.

[0037] At a temperature of 15°C-35°C, put butyl titanate and absolute ethanol in the first pear-shaped separating funnel and mix evenly to obtain the butyl titanate component, which is denoted as X component; distilled water and hydrolysis buffer Put...

Embodiment 1 2

[0048] Example 1 Binary supported TiO 2 / Nano-iron / SBA-15 catalyst preparation

[0049] Step 1: TiO 2 Loaded TiO with a loading of 15% 2 / Preparation of SBA-15 catalyst

[0050] At a temperature of 15°C-35°C, take 10mL of butyl titanate and 10mL of absolute ethanol in the first pear-shaped separating funnel and mix thoroughly to form X component, take 2.1ml of distilled water and 5ml of hydrolysis buffer in the first Mix well in a pear-shaped separating funnel to form Y component, then weigh 13.32g of SBA-15 molecular sieve with a pore size of 7nm-15nm and 100ml of butyl titanate hydrolysis buffer, mix them in a beaker, and ultrasonically disperse for 20min to form Put Z component on a magnetic stirrer, start stirring, add X component dropwise to Z component, start to drop Y component after 2 minutes, the dropping speed of X component is about 60-90 drops / min, Y group Minute rate of drop is 20-30 drops / min. During the dropwise addition of components X and Y, component C ...

Embodiment 2

[0059] Example 2 Loaded TiO 2 / Nano-iron / SBA-15 catalyst preparation

[0060] Step 1: TiO 2 Loaded TiO with 30% loading 2 / Preparation of SBA-15 catalyst

[0061] At a temperature of 15°C-35°C, take 10mL of butyl titanate and 10mL of absolute ethanol in the first pear-shaped separating funnel and mix thoroughly to form X component. Take 2.1ml of distilled water and 5ml of hydrolysis buffer in the first Mix well in a pear-shaped separating funnel to form the Y component, then weigh 5.48g of SBA-15 molecular sieve with a pore size of 7nm-15nm and 50ml of butyl titanate hydrolysis buffer, mix them in a beaker, and ultrasonically disperse for 20 minutes to form Put Z component on a magnetic stirrer, start stirring, add X component dropwise to Z component, start to drop Y component after 2 minutes, the dropping speed of X component is about 60-90 drops / min, Y group Minute rate of drop is 20-30 drops / min. During the dropwise addition of components X and Y, component C is subje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com