Method for performing flotation separation on garnet from magnetic separation brown iron ore concentrate

A technology of garnet and limonite, applied in flotation, solid separation, etc., can solve the problems of difficult separation, high garnet content, low iron concentrate grade and recovery rate, etc., and achieve simple process structure and low chemical dosage little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The technical solution of the present invention will be further described below through examples.

[0020] The method of flotation separation garnet from magnetic separation limonite concentrate of the present invention, concrete steps and medicament system are as follows:

[0021] 1. Mineral raw materials:

[0022] The content of iron in the mineral raw materials used is 47.51%, and the content of garnet is 16.24%. The phase analysis shows that iron mainly exists in the form of limonite, a small amount of hematite and hemimorphite, and the gangue minerals are mainly garnet, silicon It exists in the form of acid salt, and a small amount of silica minerals.

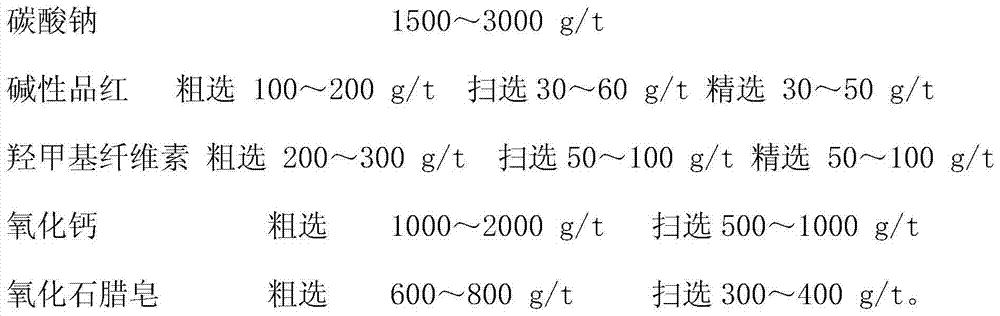

[0023] 2. Flotation agents and operating conditions:

[0024]

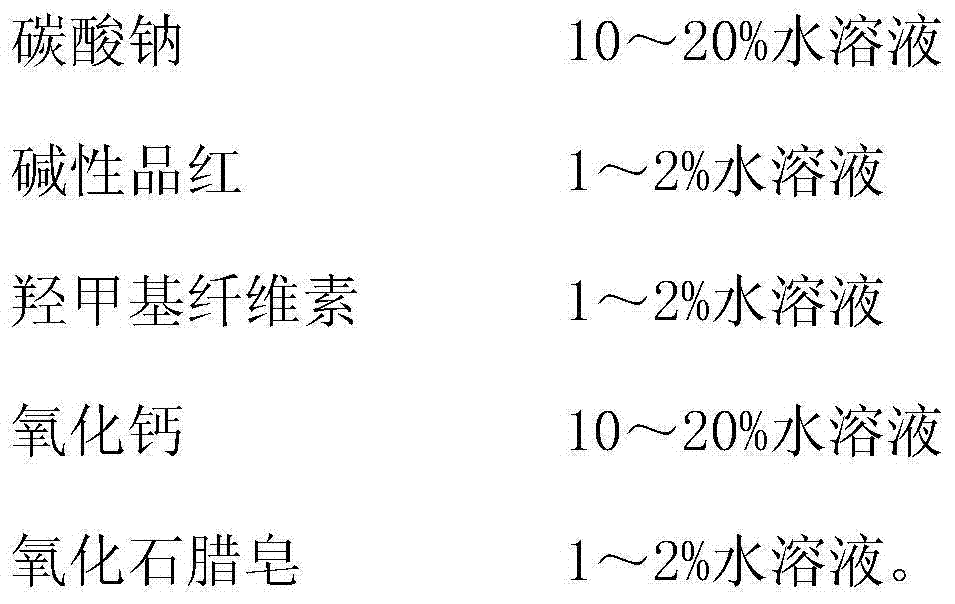

[0025] When in use, the medicament is first prepared into the following weight percent concentrations:

[0026]

[0027]

[0028] During the flotation process, add limonite concentrate to the mixing tank to adjust the pulp, add sodium carbon...

Embodiment 2

[0030] 1. Mineral raw materials:

[0031] The content of iron in the mineral raw materials used is 48.65%, and the content of garnet is 15.77%. The phase analysis shows that iron mainly exists in the form of limonite, a small amount of hematite and hemimorphite, and the gangue minerals are mainly garnet, silicon It exists in the form of acid salt, and a small amount of silica minerals.

[0032] 2. Flotation agents and operating conditions:

[0033]

[0034] When in use, the medicament is first prepared into the following weight percent concentrations:

[0035]

[0036]

[0037] During the flotation process, add limonite concentrate to the mixing tank to adjust the pulp, add sodium carbonate to adjust the pH value of the pulp to 7.5-8, then add basic fuchsin and hydroxymethyl cellulose as inhibitors of garnet, and then add Add calcium oxide as limonite activator, and finally add oxidized paraffin wax soap as limonite collector to collect limonite concentrate product....

Embodiment 3

[0039] 1. Mineral raw materials:

[0040] The content of iron in the mineral raw materials used is 49.32%, and the content of garnet is 14.91%. According to the phase analysis, iron mainly exists in the form of limonite, a small amount of hematite and hemimorphite, and the gangue minerals are mainly garnet, silicon It exists in the form of acid salt, and a small amount of silica minerals.

[0041] 2. Flotation agents and operating conditions:

[0042]

[0043] When in use, the medicament is first prepared into the following weight percent concentrations:

[0044]

[0045]

[0046] During the flotation process, add limonite concentrate to the mixing tank to adjust the pulp, add sodium carbonate to adjust the pH value of the pulp to 7.5-8, then add basic fuchsin and hydroxymethyl cellulose as inhibitors of garnet, and then add Add calcium oxide as limonite activator, and finally add oxidized paraffin wax soap as limonite collector to collect limonite concentrate produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com