System for adjusting shape and appearance of micro deep hole based on laser dual-wave combined machining

A composite processing and micro-deep hole technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of limited shape of micro-deep holes and limitations of the improvement of micro-deep hole morphology, and achieve morphology improvement, The effect of improving the morphology of micro-deep holes and adjusting the shape of micro-deep holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

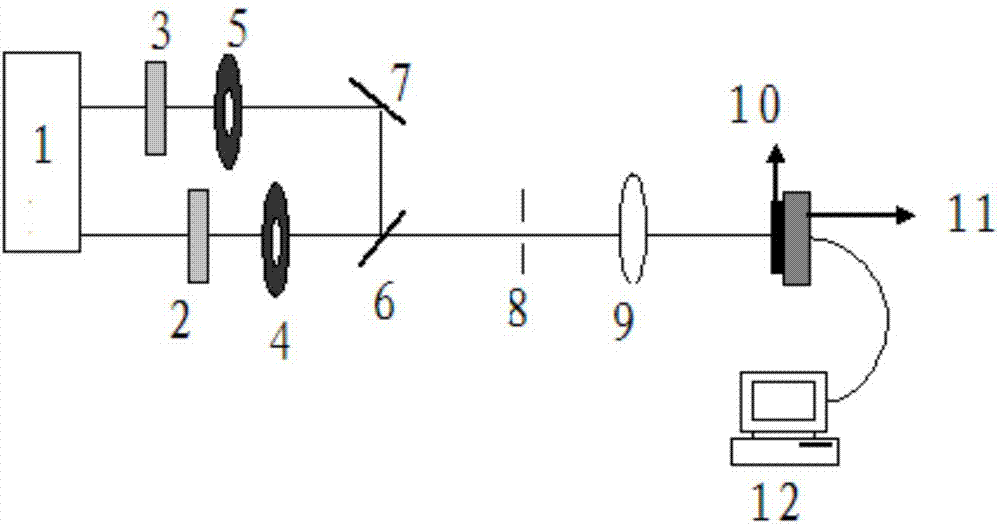

[0010] Referring to the accompanying drawings, a system for adjusting the shape and shape of micro-deep holes based on laser dual-wave composite processing includes a laser 1, which emits lasers of two different wavelengths, and an optical path passes through the first attenuator 2 and the first light in turn. Diaphragm 4, dichroic mirror 6, shutter 8, and lens 9 irradiate on the target 10, and another optical path passes through the second attenuator 3, the second diaphragm 5, reflector 7, dichroic mirror 6, and the second optical path in sequence. One light path converges to realize the collinearity of the two paths of light. The target 10 is fixed on the workbench 11 , and the control end of the workbench 11 is connected to the computer 12 .

[0011] The working principle of the present invention is: by adjusting the laser 1 to emit two different wavelengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com