Special controlled release formula fertilizer for oil palm

A formula fertilizer and oil palm technology, applied in application, fertilization device, fertilizer mixture, etc., to achieve the effect of increasing income, improving quality and plant stress resistance, and improving fertilizer utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

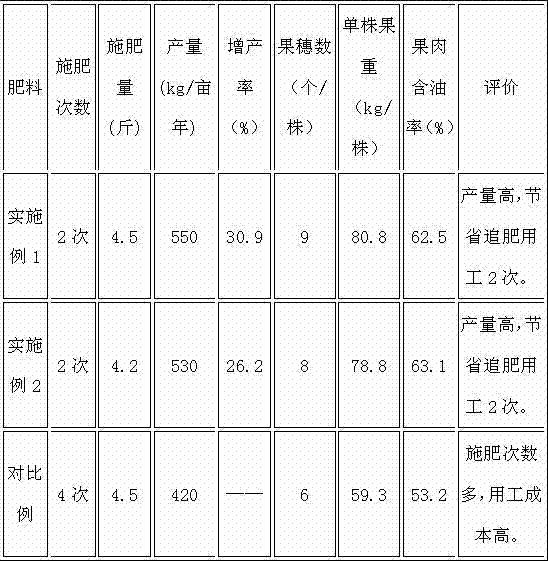

Examples

Embodiment 1

[0043] Example 1: special controlled-release formula fertilizer for oil palm, total nutrient: nitrogen, phosphorus pentoxide, potassium oxide content proportions are 18%, 9%, 18%, all are percentages by mass. The raw material components are as follows:

[0044] 60 days reaction film-forming polymer coated urea 100kg;

[0045] 150 kg of film-forming polymer-coated urea after 120 days of reaction;

[0046] 120 kg of film-forming potassium sulfate was reacted in 120 days;

[0047] Urea 100 kg;

[0048] Diammonium phosphate 190 kg;

[0049] Potassium sulfate 240 kg;

[0050] Magnesium sulfate 20 kg;

[0051]Zinc sulfate 5 kg;

[0052] Borax 20 kg;

Embodiment 2

[0053] Example 2: special controlled-release formula fertilizer for oil palm, total nutrients: nitrogen, phosphorus pentoxide, and potassium oxide content ratios are 20%, 8%, and 20% respectively, all of which are percentages by mass. The raw material components are as follows:

[0054] 60 days reaction film-forming polymer coated urea 100 kg;

[0055] 120 kg of film-forming polymer-coated urea after 120 days of reaction;

[0056] 150 kg of film-forming potassium sulfate was reacted in 120 days;

[0057] Urea 150 kg;

[0058] Diammonium phosphate 170 kg;

[0059] Potassium sulfate 250 kg;

[0060] Magnesium sulfate 30 kg;

[0061] Zinc sulfate 10 kg;

[0062] Borax 10 kg;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com