Method for graft modification of insoluble ammonium polyphosphate through organosilicon, and use of obtained product

A technology of ammonium polyphosphate and graft modification, which is applied in the treatment of dyed organic silicon compounds and fibrous fillers. The effect of easy moisture absorption, good flame retardancy, good flame retardancy and hydrophobic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Evenly disperse 10 parts of insoluble I-type ammonium polyphosphate (APP) in 15 parts of solvent acetone, add 3 parts of aminosiloxane and 1. part of MeSi (O-N=CMe 2 ) 3 , after mixing evenly, heat to 40°C, remove the solvent, dry, then heat up to 110°C, react for 30 minutes, cool to room temperature, and then pulverize to 50nm particles to obtain the modified insoluble I-type ammonium polyphosphate product. The yield is 95%.

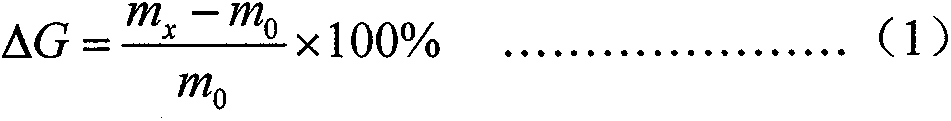

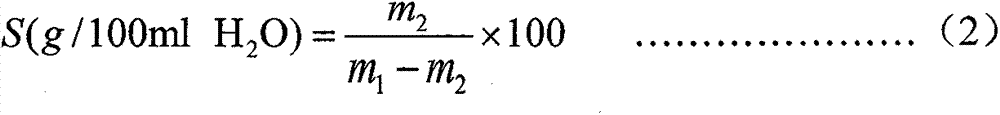

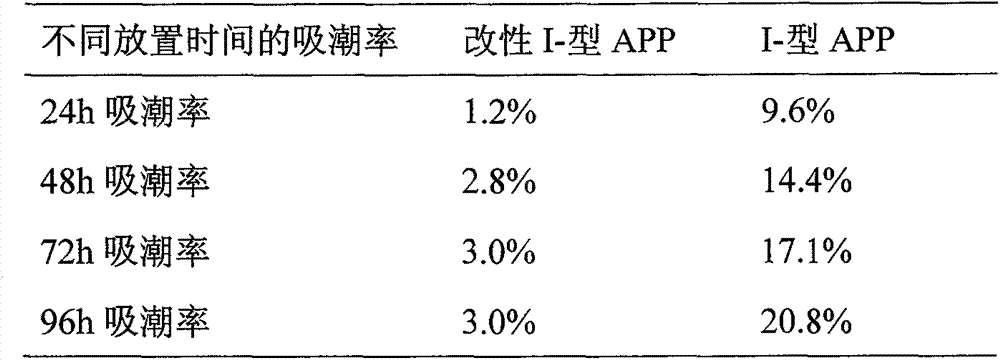

[0034] The changes in moisture absorption, dispersibility and solubility of modified I-type APP and unmodified I-type APP were respectively tested according to the aforementioned method, and the results are listed in Table 1, Table 2 and Table 3 respectively.

[0035] Table 1 Changes in the moisture absorption of modified I-type APP and unmodified I-type APP

[0036]

[0037] It can be seen from Table 1 that the moisture absorption of the modified I-type APP changes very little with time, less than 2%, and after more than 72 hours, it is bas...

Embodiment 2

[0045] Evenly disperse 10 parts of insoluble II-type ammonium polyphosphate in 35 parts of solvent petroleum ether, add 4 parts of epoxypropylsiloxane and 2 parts of CH 2 =CH-Si(O-N=CMe 2 ) 3 , after mixing evenly, heat to 50°C, remove the solvent, dry, then heat up to 130°C, react for 60 minutes, cool to room temperature, and then pulverize to 100nm particles to obtain the modified insoluble II-type ammonium polyphosphate product. The yield was 96%.

[0046] The changes in moisture absorption, dispersibility and solubility of modified II-type APP and unmodified II-type APP were tested according to the aforementioned method, and the results are listed in Table 4, Table 5 and Table 6 respectively.

[0047] Table 4 Changes in the moisture absorption of modified II-type APP and unmodified insoluble II-type APP

[0048]

[0049] As can be seen from Table 4, the moisture absorption of the modified II-type APP changes very little with time, less than 1%, and after more than 72...

Embodiment 3

[0057] Evenly disperse 12 parts of insoluble II-type ammonium polyphosphate in 55 parts of solvent toluene, add 6 parts of polydimethylsiloxane and 3 parts of MeSi (O-N=CMeEt) under stirring 3 , after mixing evenly, heat to 60°C, remove the solvent, dry, then heat up to 160°C, react for 80 minutes, cool to room temperature, and then pulverize to 150nm particles to obtain the modified II-type insoluble ammonium polyphosphate product. The yield was 97%.

[0058] The changes in moisture absorption, dispersibility and solubility of modified II-type APP and unmodified II-type APP were respectively tested according to the aforementioned method, and the results are listed in Table 7, Table 8 and Table 9 respectively.

[0059] Table 7 Changes in the moisture absorption of modified II-type APP and unmodified insoluble II-type APP

[0060]

[0061] It can be seen from Table 7 that the moisture absorption of the modified II-type APP is almost unchanged with the extension of time, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com