Preparation method of waterborne one-component polyurethane paint with low viscosity

A water-based polyurethane and oligomer technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of affecting emulsion stability, inconvenient production and application, large resin particle size, etc., and achieves extensive use of technology and excellent mechanical strength , Apply easy and quick effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

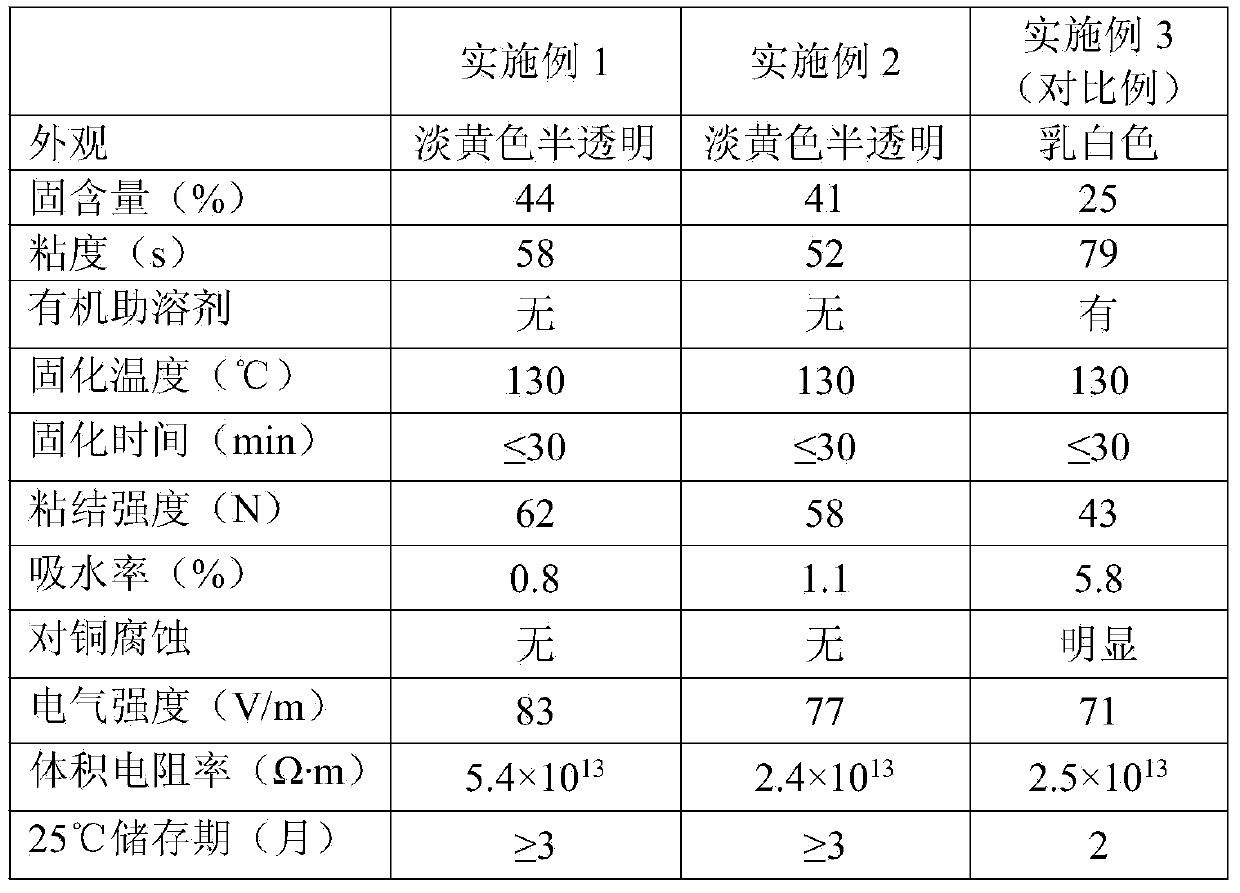

Examples

Embodiment 1

[0038] In a reaction flask protected by nitrogen and equipped with a reflux device, add 201.92 g (0.40 moles of OH) of polyphthalic anhydride diethylene glycol ester polyol with a hydroxyl value of 112 mg KOH / g after vacuum dehydration at 120 ° C, and then add 5g methyl ethyl ketone, stop heating after heating up to 50°C. Add MDI-50144.38g (1.15mol NCO) dropwise slowly with a dropping funnel. After 1.5 hours of dropping, the system automatically exotherms for 1 hour, and then reacts at 65°C for 0.5 hours. After the system is stable, add 0.18g of dibutyltin dilaurate, keep warm at 75°C until the measured NCO content is 9.08%, add an appropriate amount of acetone to adjust the viscosity to 4720mPa·s, and obtain an isocyanate-terminated oligomer.

[0039] Add 42.4 g of diethylene glycol (0.8 mol OH) and 16.75 g of dimethylol propionic acid (0.25 mol OH) in a reaction flask protected by nitrogen and equipped with a reflux device. And 13.8g of glycerin (0.45 moles of OH), then add...

Embodiment 2

[0043] In a reaction flask protected by nitrogen and equipped with a reflux device, add 140.25 g (0.3 mole OH) of polycaprolactone polyol with a hydroxyl value of 120 mgKOH / g and a polyol with a hydroxyl value of 110 mgKOH / g at 120 ° C. Propylene glycol 150g (0.3 mole OH), then add 6g methyl ethyl ketone, heat up to 50°C and stop heating. Slowly add 130.62 g of TDI (1.5 moles of NCO) dropwise with a dropping funnel. After 1.5 hours of dropping, the system automatically exotherms for 1 hour, and then reacts at 65°C for 0.5 hours. After the system is stable, add 0.2 g of dibutyltin dilaurate, keep warm at 75°C until the measured NCO content is 8.97%, add an appropriate amount of acetone to adjust the viscosity to 4290mPa·s, and obtain an isocyanate-terminated oligomer.

[0044] In a reaction flask protected by nitrogen and equipped with a reflux device, add 45.6 g (1.2 moles of OH) of propylene glycol, 20.1 g of dimethylol propionic acid (0.3 moles of OH) and trimethylol Add 20...

Embodiment 3

[0048] In a reaction flask protected by nitrogen and equipped with a reflux device, add 201.92g (0.40 mole OH) of polyphthalic anhydride diethylene glycol ester polyol with a hydroxyl value of 112mgKOH / g after vacuum dehydration at 120°C, and then add 10g Methylpyrrolidone, stop heating after heating up to 50°C. Add MDI-50144.38g (1.15mol NCO) dropwise slowly with a dropping funnel. After 1.5 hours of dropping, the system automatically exotherms for 1 hour, and then reacts at 65°C for 0.5 hours. After the system is stable, add propylene glycol, dimethylolpropionic acid and glycerin, add 0.18g of dibutyltin dilaurate, and react at 75°C. During this process, the viscosity of the system is reduced by adding acetone. When the NCO content is 0.51%, a water-based polyurethane resin is obtained, and the measured acid value is 29 mgKOH / g.

[0049] Add triethylamine to the above resin for neutralization, then add it into deionized water, emulsify and disperse at 800rpm for 30min. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com