Heavy oil composite additive

A compound additive and heavy oil technology, which is applied in the field of heavy oil additives, can solve the problems of heavy oil with many harmful impurities, large combustion smoke, and poor fluidity, and achieve the effects of environmental protection, complete combustion, and reduced fuel costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

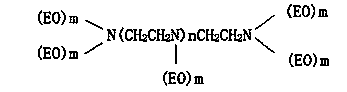

[0034] (1) At a constant temperature of 20°C, first add 8 parts of polyethylene polyamine polyether, 2 parts of polypropylene glycol, 2 parts of acetic acid, 5 parts of n-butanol, 5 parts of n-pentanol, and 30 parts of water into the mixing tank, and stir 3h;

[0035] (2) Add 5 parts of methyl tert-butyl ether and 10 parts of ethyl tert-butyl ether to the above mixture, and stir for 1 hour;

[0036] (3) Add 20 parts of polyvinylpyrrolidone to the above mixture, and stir for 1 hour;

[0037] (4) Add 3 parts of N,N-disalicylic acid-1,2-propylenediamine to the above mixture and stir for 2 hours to form a microemulsion system, which is the heavy oil composite additive product A of the present invention, which can be stored stably for 150 days without oil and water. separate.

Embodiment 2

[0039] (1) At a constant temperature of 30°C, first add 12 parts of polyethylene polyamine polyether, 7 parts of polypropylene glycol, 4 parts of acetic acid, 7 parts of n-butanol, 8 parts of n-pentanol, and 35 parts of water into the mixing tank, and stir 5h;

[0040] (2) Add 8 parts of methyl tert-butyl ether and 5 parts of ethyl tert-butyl ether to the above mixture, and stir for 2 hours;

[0041] (3) Add 28 parts of polyvinylpyrrolidone to the above mixture, and stir for 1 hour;

[0042] (4) Add 15 parts of N,N-disalicylic acid-1,2-propylenediamine to the above mixture and stir for 3 hours to form a microemulsion system, which is the heavy oil composite additive product B of the present invention. separate.

Embodiment 3

[0044] (1) At a constant temperature of 50°C, first add 17 parts of polyethylene polyamine polyether, 12 parts of polypropylene glycol, 5 parts of acetic acid, 10 parts of n-butanol, 10 parts of n-pentanol, and 50 parts of water into the mixing tank, and stir 6h;

[0045] (2) Add 10 parts of methyl tert-butyl ether and 8 parts of ethyl tert-butyl ether to the above mixture, and stir for 1 hour;

[0046] (3) Add 35 parts of polyvinylpyrrolidone to the above mixture, and stir for 2 hours;

[0047] (4) Add 10 parts of N,N-disalicylic acid-1,2-propylenediamine to the above mixture and stir for 3 hours to form a microemulsion system, which is the heavy oil composite additive product C of the present invention, which can be stably placed for 155 days without oil and water. separate.

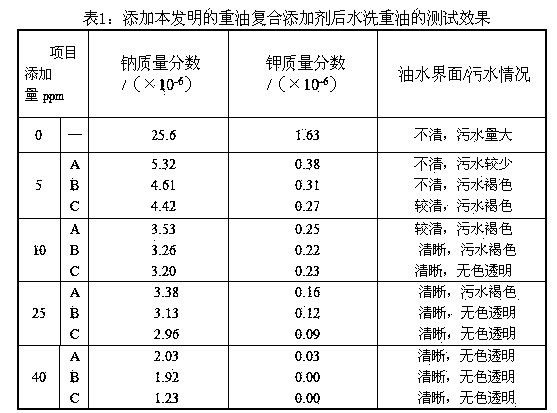

[0048] The heavy oil composite additives prepared in Examples 1-3 were added to the heavy oil according to the addition amount of 5ppm, 10ppm, 25ppm, and 40ppm for testing. The test results are shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com