Recycling method of fine slag discharged by anthracite coal water slurry gasifier and structure thereof

A gasifier and coal-water-slurry technology, which is applied in the manufacture of combustible gas, petroleum industry, solid fuel, etc., can solve the problems of high production cost, low operation efficiency and low efficiency of anthracite coal-water slurry gasification technology, etc. High load and safe and stable operation, realizing resource utilization and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

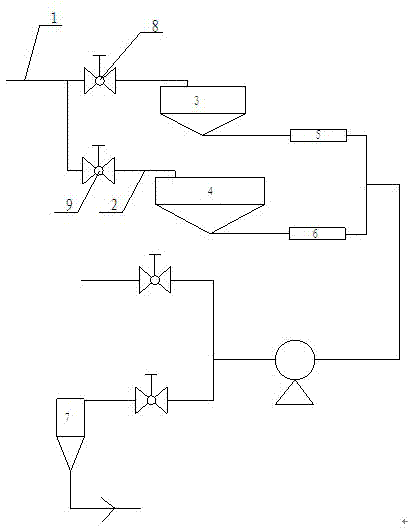

[0011] Example 1: The reuse method of the fine slag discharged from the bituminous coal-water slurry gasifier is to connect the gasified fine slag discharged from the anthracite coal-water slurry gasifier to the flotation feeding tank and the tailing coal slurry feeding tank respectively through the pump, and enter the flotation The clean coal obtained by flotation that is selected into the material tank is used for co-firing in the gasifier, and the tailing coal slime that enters the material tank is squeezed as coal slurry for co-firing in coal boilers; the waste water after flotation and pressing is recycled Grey water storage tank circulation; valves are respectively installed at the entrances of the flotation feeding tank and the tailings slime feeding tank, the opening conditions of the valves are that the flotation feeding tank is preferentially selected, and the processing capacity of the flotation feeding tank reaches the standard Close the corresponding valve and op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com