Technology for preparing antibacterial peptide

An antimicrobial peptide and process technology, applied in the field of preparation of antimicrobial peptide, can solve the problems of long production cycle, narrow antibacterial spectrum and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

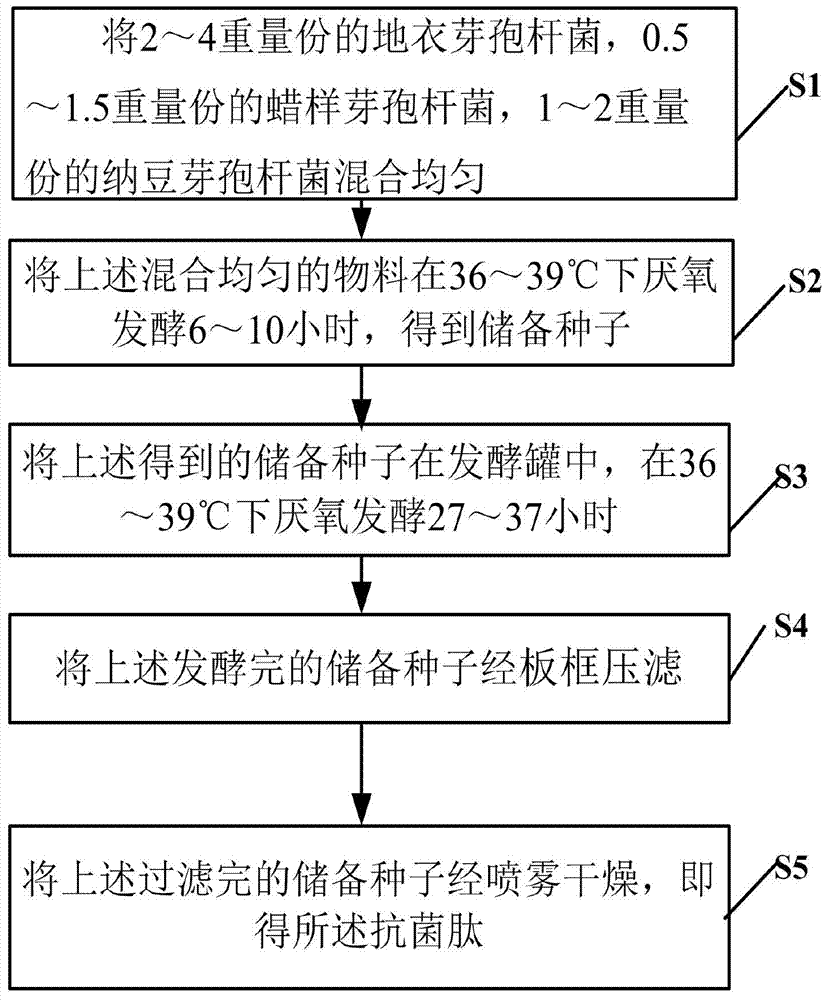

[0032] A process for preparing antimicrobial peptides, comprising the steps of:

[0033] 1) Mix 2 parts by weight of Bacillus licheniformis, 0.5 parts by weight of Bacillus cereus, and 1 part by weight of Bacillus natto;

[0034] 2) Anaerobic fermentation of the above-mentioned homogeneously mixed materials at 36°C for 6 hours to obtain reserved seeds;

[0035] 3) Anaerobic fermentation of the above-mentioned reserved seeds in a fermenter at 36°C for 27 hours;

[0036] 4) Press filter the above-mentioned fermented reserve seeds through plate and frame;

[0037] 5) The above-mentioned filtered reserve seeds are spray-dried to obtain the antimicrobial peptide.

[0038] The plate and frame filter press used in the step 4) consists of alternately arranged filter plates and filter frames to form a set of filter chambers. The surface of the filter plate has grooves, and its protruding parts are used to support the filter cloth. , There are through holes on the corners of the filt...

Embodiment 2

[0041] A process for preparing antimicrobial peptides, comprising the steps of:

[0042] 1) Mix 3 parts by weight of Bacillus licheniformis, 1 part by weight of Bacillus cereus, and 1.5 parts by weight of Bacillus natto;

[0043] 2) Anaerobic fermentation of the above-mentioned homogeneously mixed materials at 38°C for 8 hours to obtain reserved seeds;

[0044] 3) Anaerobic fermentation of the above-mentioned reserved seeds in a fermenter at 38°C for 32 hours;

[0045] 4) Press filter the above-mentioned fermented reserve seeds through plate and frame;

[0046] 5) The above-mentioned filtered reserve seeds are spray-dried to obtain the antimicrobial peptide.

[0047] The plate and frame filter press used in the step 4) consists of alternately arranged filter plates and filter frames to form a set of filter chambers. The surface of the filter plate has grooves, and its protruding parts are used to support the filter cloth. , There are through holes on the corners of the filt...

Embodiment 3

[0050] A process for preparing antimicrobial peptides, comprising the steps of:

[0051] 1) Mix 4 parts by weight of Bacillus licheniformis, 1.5 parts by weight of Bacillus cereus, and 2 parts by weight of Bacillus natto;

[0052] 2) Anaerobic fermentation of the above-mentioned homogeneously mixed materials at 39°C for 10 hours to obtain reserved seeds;

[0053] 3) Anaerobic fermentation of the above-mentioned reserved seeds in a fermenter at 39°C for 37 hours;

[0054] 4) Press filter the above-mentioned fermented reserve seeds through plate and frame;

[0055] 5) The above-mentioned filtered reserve seeds are spray-dried to obtain the antimicrobial peptide.

[0056] The plate and frame filter press used in the step 4) consists of alternately arranged filter plates and filter frames to form a set of filter chambers. The surface of the filter plate has grooves, and its protruding parts are used to support the filter cloth. , There are through holes on the corners of the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com