Environmentally friendly separation process of valuable components in biomass raw materials

A biomass raw material, environmental protection technology, applied in the direction of raw material separation, fiber raw material processing, textiles and papermaking, etc., can solve the problems affecting environmental protection effect, chemical agent consumption, etc., to achieve renewable recycling, effective separation and utilization, oxidation The effect of activity enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

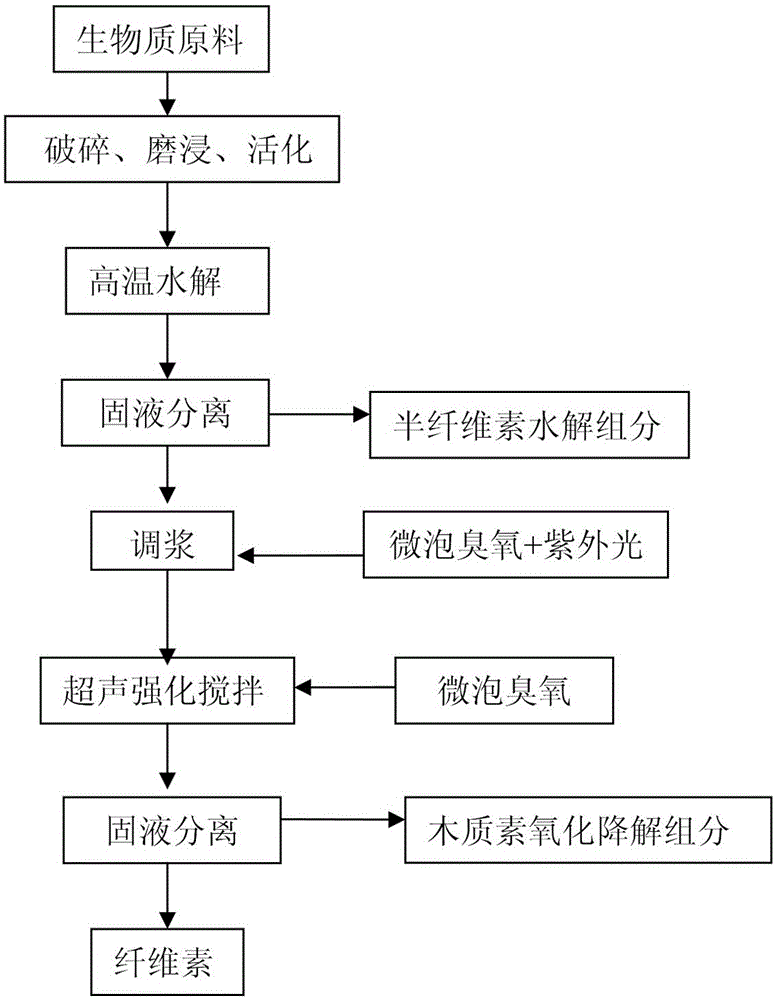

[0027] a kind of like figure 1 The environmental protection separation process of valuable components in the biomass raw material of the present invention is shown, the biomass raw material of this environmental protection separation process is derived from Hunan Yiyang Taohuajiang Industrial Co., Ltd. Phoebe wood processing waste, and the determination methods all adopt the national standard (GB / GB / T2677.2-93; GB / T2677.3-93; GB / T2677.4-93; GB / T2677.5-93; GB / T2677.2-95), the content of each component in the bamboo raw materials is shown in Table 1 shown.

[0028] Table 1: Composition of Phoebe bamboo biomass raw material.

[0029] Biomass type Cellulose (%) Hemicellulose(%) Lignin (%) Bamboo 50.20 21.95 23.67

[0030] The environmental protection separation process of the present embodiment specifically comprises the following steps:

[0031](1) First crush the bamboo biomass raw material, and the particle size of the crushed biomass raw materia...

Embodiment 2

[0038] a kind of like figure 1 The environmental protection separation process of valuable components in the biomass raw material shown in the present invention, the biomass raw material of this environmental protection separation process is derived from Hunan Yiyang Taohuajiang Industrial Co., Ltd. water bamboo processing waste, and the determination methods all adopt national standards (GB / GB / T2677.2-93; GB / T2677.3-93; GB / T2677.4-93; GB / T2677.5-93; GB / T2677.2-95), the content of each component in the bamboo raw materials is shown in Table 4 shown.

[0039] Table 4: Composition of water bamboo biomass raw materials.

[0040] Biomass type Cellulose (%) Hemicellulose(%) Lignin (%) water bamboo 53.45 21.36 19.41

[0041] The environmental protection separation process of the present embodiment specifically comprises the following steps:

[0042] (1) First crush the bamboo biomass raw material, and the particle size of the crushed biomass raw mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com